Press release

Detailed Report on Renewable Ethylene Manufacturing Plant Setup - Cost Analysis

Setting up a renewable ethylene plant facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Renewable ethylene Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a renewable ethylene processing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/renewable-ethylene-manufacturing-plant-project-report/requestsample

Renewable ethylene is ethylene, a key building block in the manufacture of many plastics and chemicals, that comes from sustainable, non-fossil fuel sources. Most conventional production of ethylene is based on cracking petroleum-based feedstocks. Renewable approaches seek to use biomass, agricultural residues, or even captured carbon dioxide as the starting material. All such processes can involve fermentation of bioethanol to sugars followed by dehydration, syngas because of gasification of biomass and conversion thereafter, or electrochemical CO2 reduction. Renewable ethylene development is paramount in establishing plastics' more circular economy and making their production process less carbon intensive. Although still in the scale-up and commercialization stages, it is a major milestone on the path to a more sustainable chemical sector, reducing our reliance on finite fossil feedstocks.

The market for renewable ethylene is undergoing strong acceleration, as the world's need to decarbonize the chemical and plastics sectors grows more pressing by the day. One major trend is the heavy investment and R&D across different production routes, such as bioethanol dehydration, biomass gasification with syngas conversion, and new technologies like carbon capture and use. The growing push from authorities and consumers for eco-friendly products is one of the key drivers, forcing manufacturers to look for alternatives in the form of bio-based ethylene rather than fossil fuel-based ethylene. In addition, the falling cost of renewable energy sources that fuel some of these production processes improves the economics of renewable ethylene. Partnerships and collaborations along the value chain from feedstock providers to polymer manufacturers are driving the development and commercialization of renewable ethylene. The ability to lower greenhouse gas emissions substantially and make the plastics industry more circular places renewable ethylene squarely in the centre of a sustainable chemical industry future.

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=28464&flag=C

Key Steps Required to Set Up a Renewable Ethylene Plant.

1. Market Analysis

The report provides insights into the landscape of the renewable ethylene industry at the global level. The report also provides a segment-wise and region-wise breakup of the global renewable ethylene industry. Additionally, it also provides the price analysis of feedstocks used in the processing of renewable ethylene, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Processing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the renewable ethylene processing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy Now: https://www.imarcgroup.com/checkout?id=28464&method=1911

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for renewable ethylene processing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for renewable ethylene production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labour, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a renewable ethylene processing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labour, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new processing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Detailed Report on Renewable Ethylene Manufacturing Plant Setup - Cost Analysis here

News-ID: 4017879 • Views: …

More Releases from IMARC Group

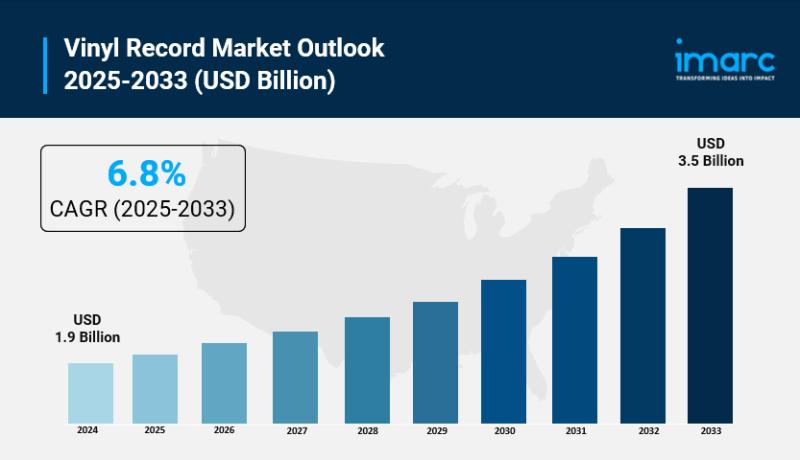

Vinyl Record Market Size to Reach USD 3.5 Billion by 2033 | With a 6.8% CAGR

Market Overview:

According to IMARC Group's latest research publication, "Vinyl Record Market Report by Product (LP/EP Vinyl Records, Single Vinyl Records), Feature (Colored, Gatefold, Picture), Gender (Men, Women), Age Group (13-17, 18-25, 26-35, 36-50, Above 50), Application (Private, Commercial), Distribution Channel (Supermarkets and Hypermarkets, Independent Retailers, Online Stores, and Others), and Region 2025-2033", The global vinyl record market size reached USD 1.9 Billion in 2024. Looking forward, IMARC Group expects the…

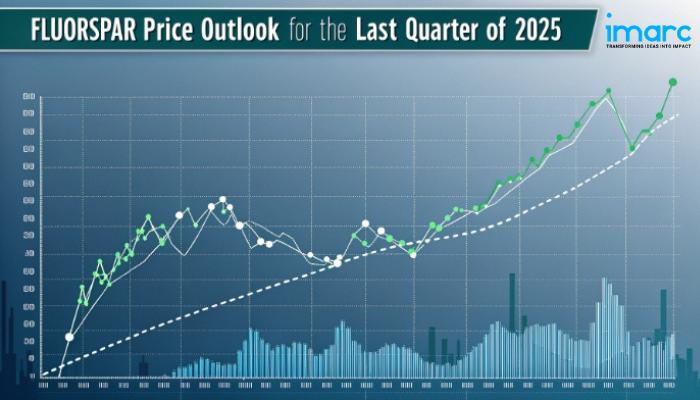

North America Fluorspar Prices Rise in Q4 2025: USA at USD 484/MT, Canada Peaks …

North America Fluorspar Prices Movement Q4 2025:

Fluorspar Prices in USA:

In Q4 2025, fluorspar prices in the USA averaged USD 484 per metric ton. Stable demand from aluminum production and chemical manufacturing supported price levels. Domestic mining operations maintained consistent output, while transportation and energy costs influenced overall supply. Moderate industrial activity and inventory management helped prevent significant price fluctuations across the regional market.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/fluorspar-pricing-report/requestsample

Note: The analysis…

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

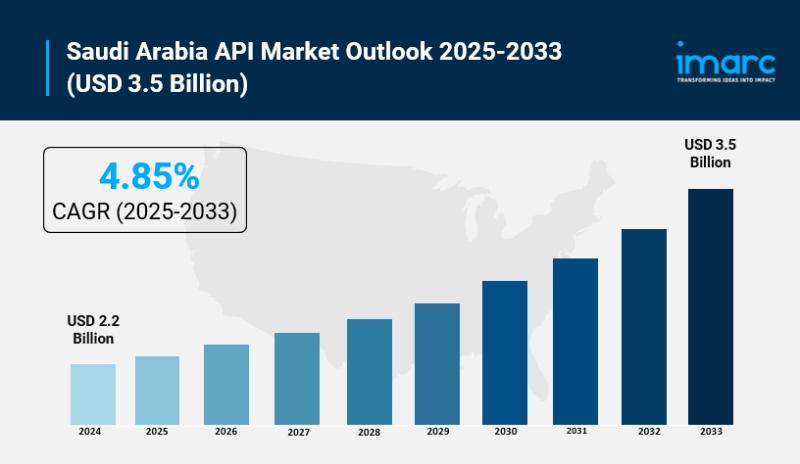

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

More Releases for Renewable

Role Of Renewable Energy Certificates In Facilitating Renewable Energy Consumpti …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts

How Large Will the Renewable Energy Certificates Market Size By 2025?

In the past few years, the renewable energy certificates market has witnessed a significant enlargement in its size. This market is projected to expand from $17.63 billion in 2024 to $22.73 billion in 2025, demonstrating a compound annual…

Israel Renewable Energy Market Size, Share Projections 2031 by Key Manufacturer- …

USA, New Jersey: According to Verified Market Research analysis, the global Israel Renewable Energy Market size was valued at USD 187.2 Million in 2024 and is projected to reach USD 1633.53 Million by 2032, growing at a CAGR of 31.1% from 2026 to 2032.

What is the current outlook of the Israel renewable energy market and what are the key growth drivers?

Israel's renewable energy market is undergoing rapid transformation. As of…

Key Trend Reshaping the Renewable Energy Storage Market in 2025: Advancements In …

"What combination of drivers is leading to accelerated growth in the renewable energy storage market?

The renewable energy storage market is anticipated to experience growth driven by the increasing investments in the energy sector. In simple terms, investing in this sector is the allocation of financial resources such as capital, funds, or assets to endeavors, projects or assets connected to the production, distribution, and use of energy. This is spurred by…

Prominent Renewable Energy Investment Market Trend for 2025: Advancements In Ren …

What Are the Projected Growth and Market Size Trends for the Renewable Energy Investment Market?

The renewable energy investment market has seen significant growth in recent years. It will rise from $309.77 billion in 2024 to $344.5 billion in 2025, at a CAGR of 11.2%. The growth is driven by public awareness of climate change, the declining costs of renewable technologies, policy incentives and mandates, concerns about energy security, and corporate…

Increasing Availability of Renewable Methanol Essential for the Global Renewable …

According to a new market research report launched by Inkwood Research, the Global Renewable Methanol Market is progressing with a CAGR of 3.82% in terms of revenue and 2.55% in terms of volume from 2022 to 2030 and is set to generate a revenue of $4119.94 million by 2030.

Browse 64 Market Data Tables and 44 Figures spread over 229 Pages, along with an in-depth analysis of the Global Renewable Methanol…

Global Renewable Chemicals Market | Global Renewable Chemicals Market: Ken Resea …

Renewable chemicals, also well-known as bio-based chemicals are generated from natural and bio-based raw materials. They are attained from the agricultural feedstock, agricultural waste, organic waste products, biomass, and microorganisms. Renewable chemicals have appeared as potential substitutes for petroleum-based chemicals as they propose fewer carbon footprints and are eco-friendly. Some of the commonly utilized renewable chemicals comprise polymeric (lignin, hemicellulose, cellulose, starch, protein) and monomeric (carbohydrates, oils, plant extractives,…