Press release

Brown Sugar Manufacturing Plant Project Report 2025: Machinery and Raw Materials

Setting up a brown sugar manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Brown Sugar Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a brown sugar manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

A brown sugar factory is a unique industrial aspect, either to produce brown sugar from sugarcane juice directly or by mixing advanced white sugar with molas. The manufacturing process typically adopts two primary approaches: direct method, wherein sugarcane juice gets partially refined, retaining natural jaggery to produce a more conventional product; And the refinery approach, involving a mix of white refined sugar and controlled volume of molasses to realize the preferred texture and flavor. The plant boasts necessary equipment like extraction equipment, clarification tanks, evaporation systems, centrifugal, drying equipment and automatic packaging lines, all harmoniously combined to ensure product quality and safety. Newer plants usually incorporate energy-efficient technology and deficiency waste systems to contribute towards environmental stability objectives. Advanced automation as well as real -time monitoring is also used to enhance operational efficiency, stability and minimize the need for manual labor. Based on the scale, these plants may cater to local markets or function as a large-scale industrial unit that supply brown sugar to food and beverages industries, bakery, confectionery and retail outlets. Sanitization procedures strictly followed and international food security certificates improve the dependability of the plant and allow access to global trade, particularly the demand for natural sweetness is growing.

The market of brown sugar manufacturing is constantly evolving with growing consumer demand for natural and less refined sweetness. Consumers understand the health effects of highly processed food, and brown sugar, as the jaggery content remains, is taken into consideration as a healthy alternative for white sugar. This follows the overall trend towards clean-labeled and organic foods. Moreover, brown sugar finds extensive applications in numerous forms of uses like baked food, sauces, drinks and ethnic foods, which is opening wider opportunities for its demand in numerous food processing industries. Greater disposable income, particularly in the emerging markets, is supporting higher consumption of premiums and specialties in food products, including brown sugar. The growth of organized retail and e-commerce sites has also enhanced access to access, providing consumers with a variety of product choices. Moreover, demand peaks during festivals and rise in consumption in home cooking and baking have positively influenced the market. Regulation favoring natural food products and more enthusiasm on permanent agriculture is being wooed to invest in the production of brown sugar. This combined factor continues to pursue the international brown sugar market, whose prospects lie in the Asia-Pacific, Latin America and Africa.

Buy Now : https://www.imarcgroup.com/checkout?id=28035&method=1911

Brown Sugar Manufacturing Plant Project Report Coverage:

1. Market Analysis

The report provides insights into the landscape of the brown sugar industry at the global level. The report also provides a segment-wise and region-wise breakup of the global brown sugar industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of brown sugar , along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

Request for a Sample Report: https://www.imarcgroup.com/brown-sugar-manufacturing-plant-project-report/requestsample

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the brown sugar manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for brown sugar manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for brown sugar production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a brown sugar manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=28035&flag=C

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: Sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

Phone Number:

- +1 631 791 1145, +91-120-433-0800

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Brown Sugar Manufacturing Plant Project Report 2025: Machinery and Raw Materials here

News-ID: 4017174 • Views: …

More Releases from IMARC Group

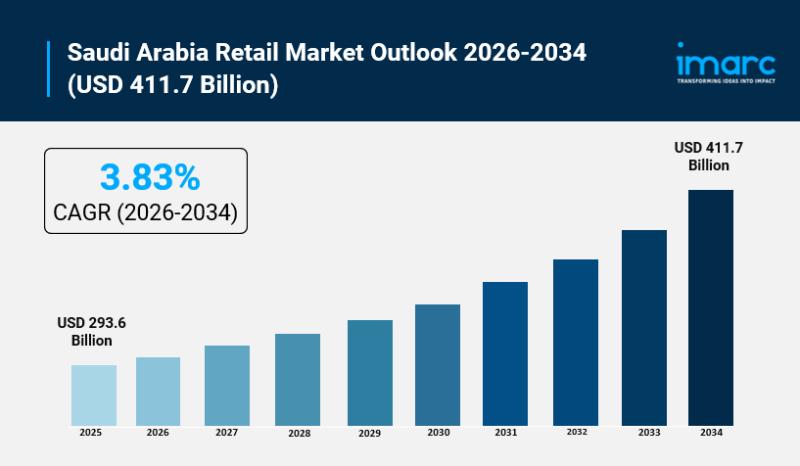

Saudi Arabia Retail Market Size to Surge to USD 411.7 Billion by 2034 | CAGR of …

Saudi Arabia Retail Market Overview

Market Size in 2025: USD 293.6 Billion

Market Size in 2034: USD 411.7 Billion

Market Growth Rate 2026-2034: 3.83%

According to IMARC Group's latest research publication, "Saudi Arabia Retail Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia retail market size was valued at USD 293.6 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 411.7 Billion by 2034, exhibiting a…

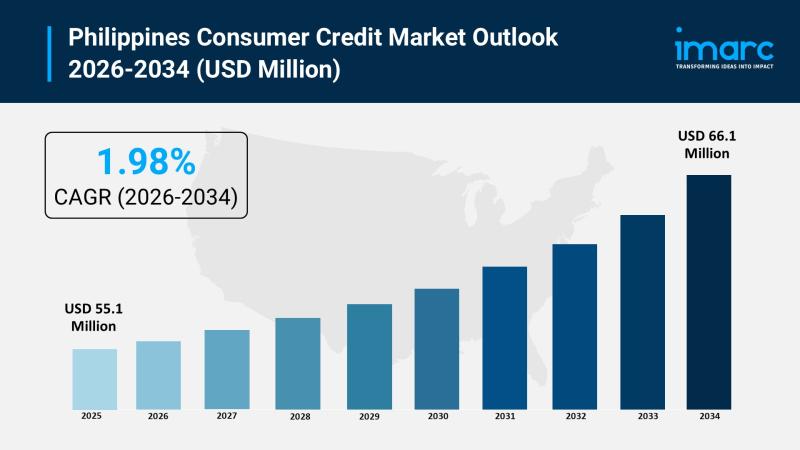

Philippines Consumer Credit Market 2026 | Worth USD 66.1 Million by 2034

Philippines Consumer Credit Market Overview:

The Philippines consumer credit market size reached USD 55.1 Million in 2025. The market is projected to reach USD 66.1 Million by 2034, exhibiting a growth rate (CAGR) of 1.98% during 2026-2034. The market is expanding steadily as rising financial inclusion, mobile-first lending platforms, and Buy Now Pay Later adoption bring formal credit to previously underserved Filipinos. Fintech innovation, neobank growth, and supportive BSP regulatory frameworks…

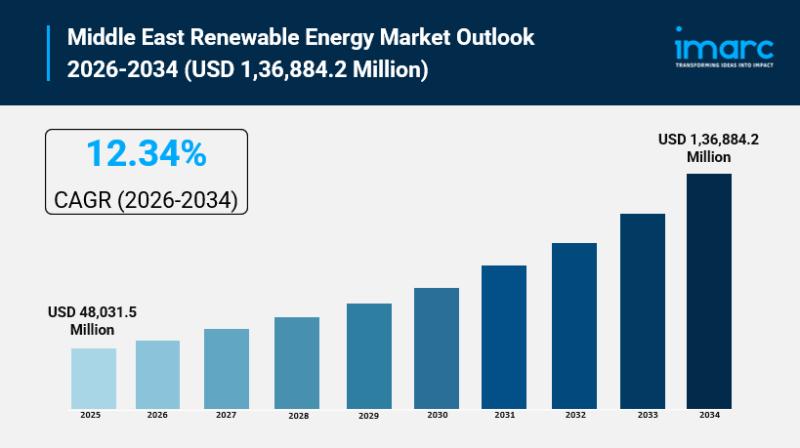

Middle East Renewable Energy Market Size to Hit USD 1,36,884.2 Million by 2034 | …

Middle East Renewable Energy Market Overview

Market Size in 2025: USD 48,031.5 Million

Market Size in 2034: USD 1,36,884.2 Million

Market Growth Rate 2026-2034: 12.34%

According to IMARC Group's latest research publication, "Middle East Renewable Energy Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Middle East renewable energy market size was valued at USD 48,031.5 Million in 2025. Looking forward, IMARC Group estimates the market to reach USD 1,36,884.2 Million by…

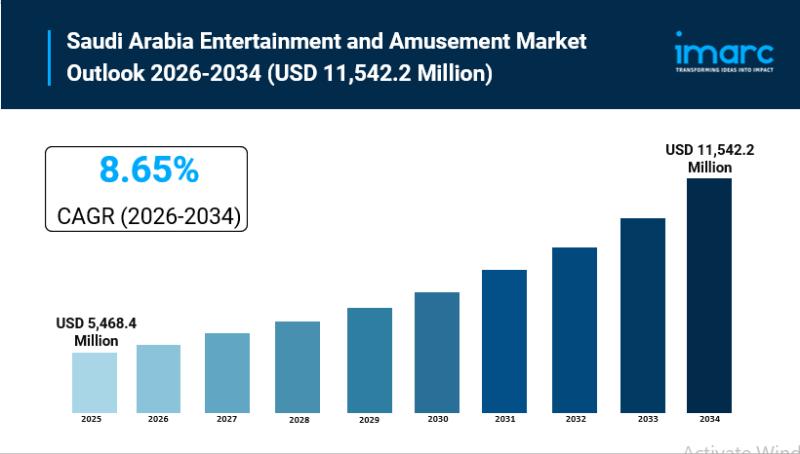

Saudi Arabia Entertainment and Amusement Market Size to Reach USD 11,542.2 Milli …

Saudi Arabia Entertainment and Amusement Market Overview

Market Size in 2025: USD 5,468.4 Million

Market Size in 2034: USD 11,542.2 Million

Market Growth Rate 2026-2034: 8.65%

According to IMARC Group's latest research publication, "Saudi Arabia Entertainment and Amusement Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Saudi Arabia entertainment and amusement market size reached USD 5,468.4 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 11,542.2 Million…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…