Press release

Feed Premix Manufacturing Plant Cost- Detailed Project Report

Setting up a feed premix manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Feed Premix Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a feed premix manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Feed premix is a specialized blend of essential nutrients, vitamins, minerals, and other additives mixed with animal feed to enhance its nutritional value and promote animal health. It is a concentrated form of feed additives, conveniently combined in accurate proportions to ensure optimal nutrition for livestock and poultry. Feed premixes are widely utilized in the agriculture industry, particularly in animal husbandry, to improve the growth, productivity, and overall well-being of livestock. These premixes are formulated to meet the specific dietary requirements of different animal species, ensuring a balanced and complete diet that may be lacking in certain nutrients.

The rising population across the globe and increasing per capita meat consumption are encouraging farmers and animal producers to use feed premix that will optimize their production processes and ensure the health and growth of their animals, contributing to the market growth. Moreover, the growing product utilization owing to its nutritional supplements and additives that contribute to improved animal performance, enhanced immune function, and efficient feed utilization is creating a positive outlook for the market. Additionally, the growing awareness among consumers about the quality and safety of animal-derived food products has led to an increased focus on animal welfare and sustainable farming practices, providing an impetus to the market growth. In addition to this, rapid advancements in feed formulation technologies and ongoing research and development (R&D) efforts have resulted in the development of specialized premixes that target specific animal species and production stages, which enable precise nutrient delivery, improved digestibility, and better feed conversion rates, thereby increasing the profitability of animal production operations, which in turn, is providing a considerable boost to the market growth. Besides this, the growing popularity of feed premix due to the emergence of customized feed premix solutions tailored to meet the unique nutritional requirements of different livestock categories, such as poultry, swine, cattle, and aquaculture, is providing remunerative growth opportunities.

Request for a Sample Report: https://www.imarcgroup.com/feed-premix-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up a Feed Premix Plant.

1. Market Analysis

The report provides insights into the landscape of the feed premix industry at the global level. The report also provides a segment-wise and region-wise breakup of the global feed premix industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of feed premix, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the feed premix manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy Now: https://www.imarcgroup.com/checkout?id=30604&method=1911

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for the feed premix manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for feed premix production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=30604&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a feed premix manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Feed Premix Manufacturing Plant Cost- Detailed Project Report here

News-ID: 4015919 • Views: …

More Releases from IMARC Group

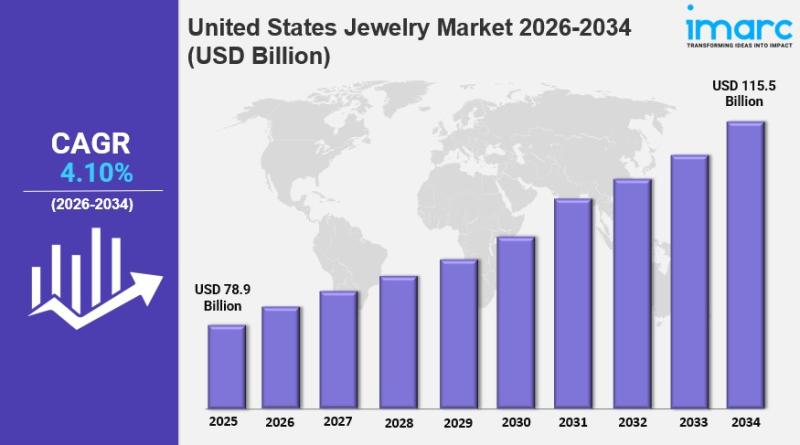

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for Feed

Feed Mycotoxin Modifiers: Enhancing Animal Health and Feed Safety

Introduction

Mycotoxins are toxic compounds produced by molds and fungi that frequently contaminate animal feed. When animals consume feed containing these toxins, it can negatively impact their health, resulting in lower productivity and financial losses for the livestock industry. Feed mycotoxin modifiers are specially designed products that neutralize or reduce the harmful effects of mycotoxins, ensuring that animals receive safe and nutritious feed. These products play a critical role in maintaining…

Fish, Fish Feed, Fish Feed Additives, Shrimp, Shrimp Feed, Shrimp Feed Additives …

Market Overview:

Feeding these aquatic animals food is referred to as feeding fish and shrimp. To increase the end product quality of fish or shrimp, to preserve the physical and chemical quality of their diet, or to preserve the quality of the aquatic environment, additives are nutritional elements that are supplemented in small amounts.

The producers of compound feed, integrators, farmers, home-mixers, animals, and participants in the aquaculture business are the final…

Animal Feed & Feed Additives Market | Global Industry Report 2026

The global animal feed and feed additives market is progressing at a CAGR of 4.1% from 2018 to 2026, according to a research report released by leading market intelligence provider, Transparency Market Research. This market was valued at US$17.5 bn in 2018 and is expected to reach US$24.1 bn by the end of 2026.

Read report Overview-

https://www.transparencymarketresearch.com/animal-feed-and-feed-additives-market.html

The above data feature in a new TMR research report, titled "Animal Feed and Feed…

Aqua Feed

Global Aquafeed Market

Aquafeed is a compounded feed prepared by mixing of various raw materials with additives, which are administered to various aquatic species such as crustaceans, fish, and mollusks for aquatic species growth. Aquafeed is commonly used in the aquaculture sector and prepared according to the specific requirements of the age and species of animals. Aquafeed is available as the medicated and non-medicated feed. Medicated feed is used for the…

Poultry Feed Market Report 2018: Segmentation by Type (Complete Feed, Concentrat …

Global Poultry Feed market research report provides company profile for Tyson Foods, BRF, ForFarmers, Twins Group, East Hope Group, JA Zen-Noh, Haid Group, CP Group, Cargill, New Hope Group, Purina Animal Nutrition, Nutreco and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and…

Global Feed Preservatives Market, Types (Mixed Feed and Feed Raw Materials) Natu …

Feed preservatives are used in animal food products to avoid any spoilage of food product and enhance shelf life. Especially in animal food products, preservatives or antioxidants are essential to avoid animal fats and oils from oxidizing. They are also essential in kibble or dry pet food products.

For further inquiries, about Global Feed Preservatives Market enquire here >>>> https://www.progressivemarkets.com/enquiry-about-report/feed-preservatives-market

Preservatives are available in two forms, namely, natural and artificial…