Press release

Overcoming TPU Limitations in Nylon Overmolding: Si-TPV 3525-65A Delivers Superior Bonding and Tactile Comfort - A Comparative Study

Why Is Soft Overmolding on Nylon So Important?Nylon, as an engineering plastic, is widely used in various applications due to its excellent mechanical properties. However, its rigid surface often leads to a poor tactile experience and potential skin abrasion during human contact. To address this, soft elastomers with Shore hardness ranging from 40A to 80A (typically 60A~70A) are overmolded onto nylon substrates, providing skin-friendly protection, enhanced tactile comfort, and greater design flexibility.

Traditional physical bonding methods (e.g., snap-fit designs, knurling, or threaded surfaces) for nylon overmolding suffer from inconsistent adhesion strength and limited design freedom. In contrast, chemical bonding leverages molecular affinity, polarity, or hydrogen bonding between materials, ensuring uniform adhesion across the interface and enabling complex geometries.

The Drawbacks of Using TPU for Nylon Overmolding

Thermoplastic Polyurethane (TPU) is widely used for overmolding onto nylon due to its wear resistance and good mechanical balance. It is often considered compatible with nylon due to their similar polarity. However, TPU often suffers from poor interfacial adhesion, leading to peeling or delamination, especially in high-stress or long-term use scenarios-ultimately compromising product quality and performance.

Solution: Introducing Si-TPV 3525- 65A, TPU alternative, the best elastomer for nylon overmolding [https://www.si-tpv.com/si-tpv-overmolding-of-tool-handles-redefines-ergonomics-boosting-safety-and-comfort-product/]

To address the limitations of TPU, Silike has developed Si-TPV 3525- 65A-a silicone-thermoplastic vulcanizate elastomer that maintains the desirable properties of TPU while significantly improving adhesion to nylon substrates.

This innovative soft overmolding Si-TPV thermoplastic elastomer material [https://www.si-tpv.com/si-tpv-overmolding-of-tool-handles-redefines-ergonomics-boosting-safety-and-comfort-product/] offers:

1. Excellent chemical bonding with PA6, PA12, and PA66

2. Durable, uniform overmolding interface

3. Soft-touch surface with enhanced user comfort

4. Outstanding mechanical durability, water, oil resistance, and cold flexibility

Superior Overmolding Performance of Si-TPV 3525- 65A on Nylon Substrates, A Comparative Study with TPU for Enhanced Bonding and Tactile Comfort!

Testing the Adhesion: Standardized Overmolding Evaluation

To compare bonding performance, Si-TPV and TPU were tested using a standardized overmolding procedure:

Nylon (PA6) substrates were injection-molded, then diagonally cut at 45 degrees and polished with 120-grit sandpaper.

The treated substrates were reinserted into molds for overmolding under controlled temperature and pressure.

Tensile tests were conducted to evaluate interfacial bonding strength.

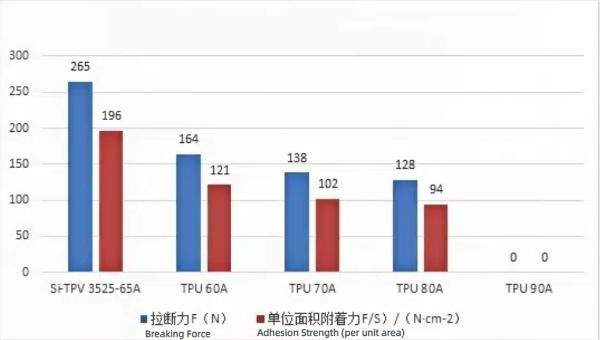

TPU vs. Si-TPV 3525- 65A on PA6: Tensile Force at Break & Adhesion Test Results

Image: https://www.si-tpv.com/uploads/Improve-Nylon-Product-Design-with-Soft-Touch-Overmolding-with-Si-TPV-3525-65A-Solutions.pngImage: https://www.si-tpv.com/uploads/Superior-Bonding-to-PA6-PA12-and-PA66-Si-TPV-3525-65A-Adhesion-Performance-Explained1.pngImage: https://www.si-tpv.com/uploads/TPU-for-Nylon-Overmolding1.png

TPU Overmolding on PA Substrates :

As TPU hardness increased (60A to 90A), bonding strength to PA6 significantly dropped. At 90A, TPU failed to bond entirely.

Si-TPV 3525-65A Overmolding, TPU alternative for nylon overmolding:

Demonstrated strong and consistent bonding with PA6. Cross-sectional analysis revealed cohesive failure-Si-TPV remained attached to both sides of the interface, proving strong chemical bonding. In contrast, TPU interfaces showed minimal residue, indicating weak adhesion.

Soft-touch material Si-TPV 3525- 65A on all kind of Nylon Grades: Reliable Across PA6, PA12, PA66

Modified Silicone Elastomer 3525- 65A also achieved robust bonding across multiple nylon types.

Non-Sticky Thermoplastic Elastomer Si-TPV 3525- 65A on PA12, overmolding showed no visible separation during testing, confirming true cohesive bonding without interface failure.

Plasticizer-Free Elastomers Si-TPV [https://www.si-tpv.com/si-tpv-overmolding-of-tool-handles-redefines-ergonomics-boosting-safety-and-comfort-product/]3525- 65A on PA66, the material maintained strong adhesion and structural integrity under load.

(Note: All Shore hardness values and test procedures align with international elastomer and adhesion testing standards.)

Goodbye TPU Peeling - Upgrade to Skin-Friendly, Soft-Touch Si-TPV for Durable Nylon Overmolding

Si-TPV 3525- 65A combines the mechanical resilience of TPU with the soft touch and chemical adhesion of silicone. It offers a breakthrough overmolding solution for nylon components used in consumer electronics, automotive interiors, and industrial tools.

By switching to Si-TPV, manufacturers can eliminate TPU peeling issues, extend product lifespan, deliver safety, aesthetics, and superior ergonomic performance.

Tel: +86-28-83625089 or +86-15108280799

Email: amy.wang@silike.cn

Website: www.si-tpv.com

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=overcoming-tpu-limitations-in-nylon-overmolding-sitpv-352565a-delivers-superior-bonding-and-tactile-comfort-a-comparative-study]

Country: China

Website: https://www.si-tpv.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Overcoming TPU Limitations in Nylon Overmolding: Si-TPV 3525-65A Delivers Superior Bonding and Tactile Comfort - A Comparative Study here

News-ID: 4013878 • Views: …

More Releases from ABNewswire

Family-Based Immigration Lawyer in San Diego, CA, Emphasizes Importance of Perso …

San Diego, CA - In the complex landscape of family-based immigration, no two cases are identical. Each couple, each family unit, and each set of circumstances requires a tailored approach that addresses specific challenges and maximizes the likelihood of success. Jason Feldman of Feldman Feldman & Associates PC understands this reality and has built his practice around delivering customized legal strategies that respond to the unique needs of every client.

"Family…

Expert Witness for Legal Malpractice in Arizona Warns Attorneys About Pitfalls i …

Tucson, AZ - A critical misstep in expert witness management is exposing Arizona attorneys' case strategies. David J. Leonard, is alerting the legal community about consequences of inadvertently converting consulting experts into testifying experts, a change that eliminates discovery protections. Raised in New York City, Leonard relocated to Arizona in 1958 and continues practicing full time after six decades.

Under Arizona law, consulting experts not expected to testify enjoy broad protections…

Stafili Wine Cafe Brings the Spirit of Greece to the Heart of New York with an U …

In a city known for its world-class dining and vibrant nightlife, Stafili Wine Cafe stands out as a warm, inviting haven where Greek heritage meets modern New York energy. With locations in West Village and Tribeca, Stafili Wine Cafe has quickly become a destination for wine lovers, food enthusiasts, and anyone seeking an intimate atmosphere rooted in hospitality, flavor, and culture.

New York, NY - In a city known for its…

Optimal Health Chiropractic Launches Cold, Flu & Allergy Campaign in Studio City …

As seasonal colds, flu outbreaks, and persistent allergies continue to affect families across the San Fernando Valley, Optimal Health Chiropractic is proud to announce a focused Cold, Flu & Allergy Campaign designed to support the immune system naturally. Led by Dr. Patrick Bennett, who has served the community for over 25 years, the clinic is highlighting the powerful role chiropractic care can play in strengthening the body's defenses and promoting…

More Releases for TPU

High-Performance Soft TPU Modifier for Matte TPU Films | Soft-Touch, Non-Sticky, …

You've adjusted the formulation, slowed the cooling rate, and even changed the resin grade - but the TPU film still ends up sticky, not soft enough, and prone to color loss after aging. These persistent drawbacks limit design freedom, reduce visual appeal, and undermine performance stability. What if the solution didn't require redesigning your entire process, and instead came from enhancing the TPU material itself? SILIKE Soft TPU Modifier particles(https://www.si-tpv.com/soft-modified-tpu-particle-series/)…

Global Demand for TPU Filament From China Spurs New TPU Filament Manufacturer In …

The global movement towards additive manufacturing is revolutionizing supply chains and product development cycles across multiple industrial sectors, leading to rapid adoption of high-performance materials like Thermoplastic Polyurethane (TPU). TPU filament in particular is notable for its combination of elasticity, durability and chemical resistance - something which Chinese producers are taking advantage of by investing heavily and diversifying into flexible polymers manufacturing as part of a competitive edge they possess…

Application of TPU Material in Humanoid Robots

TPU (Thermoplastic Polyurethane) [https://www.ytlinghua.com/polyether-tpu/] has outstanding properties such as flexibility, elasticity, and wear resistance, making it widely used in key components of humanoid robots like exterior covers, robotic hands, and tactile sensors. Below are detailed English materials sorted out from authoritative academic papers and technical reports:

1. Design and Development of an Anthropomorphic Robotic Hand Using TPU Material [https://www.ytlinghua.com/polyether-tpu/]The paper presented here approaches to solve the complexity of an anthropomorphic robotic…

TPU (Thermoplastic Polyurethane) Main Industry Applications

TPU (Thermoplastic Polyurethane [https://www.ytlinghua.com/t3-series-tpu/]) is a versatile material with excellent elasticity, wear resistance, and chemical resistance. Here are its main applications :

1. Footwear Industry - Used in shoe soles, heels, and upper parts for high elasticity and durability. - Commonly seen in sports shoes, outdoor footwear, and casual shoes to enhance shock absorption and grip.

2. Automotive Sector [https://www.ytlinghua.com/polyester-type-tpu-h3-series-product/] - Manufactures seals, gaskets, and weather strips for their flexibility and resistance…

Addressing the Limitations of Traditional TPU and Innovations for EV Charging Ca …

TPU is a versatile material known for its hardness and elasticity, making it popular in various applications. However, traditional TPU faces challenges in meeting the specific performance demands of industries such as automotive, consumer goods, and medical devices. These challenges include inadequate surface quality, high hardness levels limiting flexibility, and a lack of desirable tactile properties, which can impact user experience and product longevity.

Solutions: Modified TPU Technology

The modification of TPU…

Professional 3d printing manufacturer for TPU

What is TPU

TPU is a stands for Thermoplastic Polyurethane. It is a subset of TPE and is a soft polyether type polyurethane that comes in a range of hardness grades. At the same time, TPU also as the one of material be commonly used in injection industry. But today we want to show you another craft to process TPU, that is 3D Printing. Have you ever thought about 3D…