Press release

Conveyors In Food Market to Benefit from Advancements in Hygienic Design and Processing Efficiency: Persistence Market Research

The global conveyors in the food market have witnessed substantial growth due to the rising demand for food automation and the need for improved sanitation. These systems play an essential role in food production and processing by facilitating the movement of raw and processed food products across different stages. Over time, conveyors have evolved to cater to the specific needs of various food sectors, including meat, dairy, bakery, and snacks. This article provides an in-depth look at the market, including key growth drivers, regional trends, segmentation, and the outlook for the future.Get a Sample Copy of Research Report (Use Corporate Mail id for Quick Response):

https://www.persistencemarketresearch.com/samples/23611

✅ Overview of the Market

The food industry is a significant contributor to the global economy, with conveyors being an integral part of food manufacturing and packaging lines. The growing demand for processed foods, coupled with advancements in automation technology, has resulted in an increased reliance on conveyors for improving efficiency, ensuring quality, and meeting high production standards. In 2024, the global market for conveyors in the food industry is expected to see a surge in demand, driven by the need for improved sanitation, hygiene standards, and better manufacturing capabilities.

Key market drivers include the growing adoption of automated systems, rising consumer demand for convenience foods, and the increasing focus on food safety regulations. These factors have prompted manufacturers to invest in state-of-the-art conveyor systems that not only streamline production but also meet the high hygiene standards required in the food industry. The North American and European markets are currently leading the industry, driven by regulatory standards, whereas the Asia Pacific region is showing significant potential due to a large population base and growing food processing industries.

✅ Key Growth Drivers Behind Market Growth

Automation and Technological Advancements: The adoption of automation technologies in food production and packaging lines has led to increased demand for conveyors. These systems help in reducing human labor, improving speed, and enhancing accuracy in food processing.

Rising Demand for Processed Foods: As consumer demand for ready-to-eat and packaged foods rises, the need for efficient food production processes has spiked, driving the demand for conveyors.

Stringent Hygiene and Sanitation Regulations: Government regulations surrounding food safety have encouraged manufacturers to invest in conveyors that are easy to clean, durable, and resistant to contamination.

Increased Investments in Food Processing: Growing investments in food manufacturing facilities and cold chain logistics, particularly in emerging markets, are contributing to the demand for conveyor systems.

✅ Leading Segment and Geographical Region

The bakery sector has emerged as the leading segment in the food conveyor market. This is primarily due to the high volume of products that require handling, packaging, and moving during production. Bakery items, from breads to pastries, require precision, speed, and reliability in production, making conveyors indispensable for their efficient movement.

Geographically, North America is expected to remain the dominant region for the conveyor market due to stringent food safety regulations and high demand for automated solutions in food manufacturing. The food processing industry in North America is heavily regulated, necessitating the adoption of high-quality, easy-to-clean conveyor systems.

✅ Key Highlights from the Report

➤ The conveyors in the food market are projected to experience significant growth over the forecast period.

➤ Bakery and meat processing are the leading end-user segments driving demand for conveyors in the food industry.

➤ Technological advancements in automation and conveyor design are key drivers of market growth.

➤ North America leads the market, driven by food safety regulations and high demand for efficient production.

➤ Asia Pacific is expected to experience substantial growth due to increasing investments in food processing and packaging infrastructure.

➤ Conveyor systems are becoming more adaptable to different food production lines, ensuring high efficiency and sanitation.

✅ Market Segmentation

Product Type-Based Segmentation

The food conveyor market is broadly segmented into different product types, including belt conveyors, metal conveyors, and modular conveyors. Belt conveyors, for instance, are highly popular in the food industry due to their flexibility, ease of integration, and efficiency in handling a variety of food products, from raw materials to finished goods.

Conveyors are also differentiated by material, with the most common being plastic, rubber, and stainless steel. Stainless steel conveyors are preferred in the food industry due to their ability to withstand harsh cleaning processes, resistance to corrosion, and durability. Plastic and rubber conveyors, on the other hand, are used where flexibility and lightweight solutions are needed.

End-User Segmentation

The conveyors in the food industry cater to a range of end-user sectors, including bakery, meat, dairy, poultry, and beverage industries. Each of these segments requires specific conveyor designs to handle the different types of food products and meet the respective safety regulations.

Bakery: Conveyors in the bakery industry are primarily used for transporting baked goods from one production stage to another, such as from ovens to packaging units. These conveyors are often designed to handle high temperatures.

Meat Processing: Conveyors in the meat processing industry are typically heavy-duty, able to transport large and sometimes irregularly shaped products through the various stages of processing.

Dairy: Dairy conveyors are designed to transport delicate products like milk and cheese, requiring gentle handling and proper sanitation features to avoid contamination.

✅ Regional Insights

North America

North America has been a significant market for conveyors in the food industry, owing to the strict food safety regulations and a growing preference for automation in food production. The U.S. and Canada are major contributors to the market, driven by advancements in cold chain logistics, food processing, and packaging technologies. The region also benefits from increased demand for ready-to-eat foods, which accelerates the need for efficient food handling solutions.

Asia Pacific

The Asia Pacific region is poised for substantial growth in the conveyors in food market, mainly due to a large population base in countries like China and India. The increasing urbanization, along with rapid industrialization, is pushing the demand for advanced food processing technologies. As the demand for packaged foods rises in this region, manufacturers are investing in conveyors to enhance efficiency and meet the rising food production requirements.

✅ Market Drivers

The food conveyor market is heavily influenced by several key drivers that contribute to its growth.

Increased Automation in Food Production: The shift toward automation has led to reduced labor costs and higher production efficiency. Automated conveyor systems allow for faster processing, reduced downtime, and greater consistency in food quality.

Hygiene and Safety Regulations: Stringent government regulations on food safety, including the need for easy-to-clean equipment, are driving the demand for conveyor systems that meet these standards.

Demand for Processed Foods: The growing demand for convenience foods is pushing the food industry to adopt advanced technologies such as conveyors that can streamline production lines.

✅ Market Restraints

Despite the market's growth prospects, several factors could restrain its progress.

High Initial Investment: The cost of installing automated conveyor systems can be prohibitively high, especially for small and medium-sized enterprises (SMEs), which may delay adoption.

Maintenance Costs: Conveyor systems require regular maintenance to ensure optimal performance. The cost of maintenance and replacement parts can be a barrier to long-term adoption for some manufacturers.

✅ Market Opportunities

Several opportunities are emerging within the conveyors in food market.

Smart Conveyor Solutions: There is an increasing demand for conveyors that integrate IoT capabilities for real-time monitoring and predictive maintenance, providing an opportunity for innovation.

Expansion into Emerging Markets: As food processing industries expand in regions like Asia Pacific, Latin America, and Africa, there is a significant opportunity for conveyor manufacturers to tap into these rapidly developing markets.

✅ Frequently Asked Questions

➤ How Big is the Market for Conveyors in the Food Industry?

➤ Who are the Key Players in the Global Market for Conveyors in Food?

➤ What is the Projected Growth Rate of the Market for Conveyors in Food?

➤ What is the Market Forecast for Conveyors in Food by 2032?

➤ Which Region is Estimated to Dominate the Industry for Conveyors in Food through the Forecast Period?

✅ Company Insights

Some of the key players in the conveyors in food industry include:

✦ Dorner GmbH

✦ Air Draulic Engineering (ADE)

✦ Canning Conveyor Co Ltd

✦ KOFAB

✦ Belt Technologies, Inc.

✦ Triple/S Dynamics, Inc.

✦ LM Manutentions

✦ Vis GmbH

✦ COBRA Group

✦ Floveyor

✦ VERMA FOOD PROCESSING SYSTEM

✅ Recent Developments

■ In 2024, Dorner GmbH launched a new series of stainless steel conveyors designed specifically for the food industry to meet stringent hygiene standards.

■ KOFAB introduced modular conveyors that can be easily customized to suit different production line setups in the bakery and dairy sectors.

✅ Conclusion

The conveyors in the food market are experiencing significant growth due to the increasing demand for automation, better food safety, and efficient production systems. With continued advancements in technology and growing investments in food manufacturing facilities, the industry is expected to evolve, with North America and Asia Pacific leading the charge. As the market expands, food manufacturers will continue to embrace conveyor systems that improve efficiency, reduce operational costs, and maintain high standards of sanitation.

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Conveyors In Food Market to Benefit from Advancements in Hygienic Design and Processing Efficiency: Persistence Market Research here

News-ID: 4005314 • Views: …

More Releases from Persistence Market Research

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

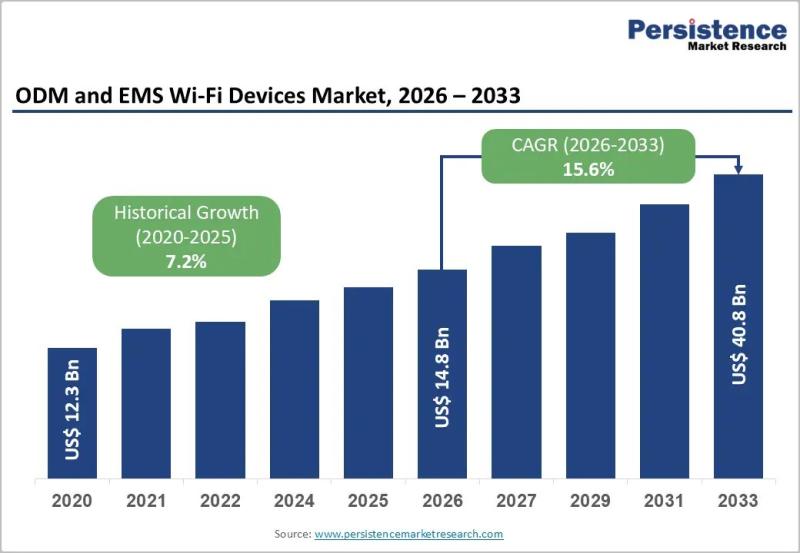

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

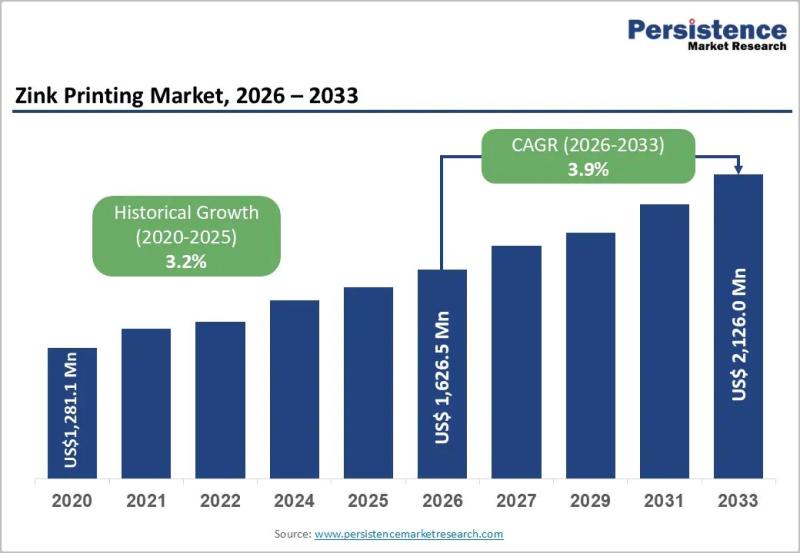

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

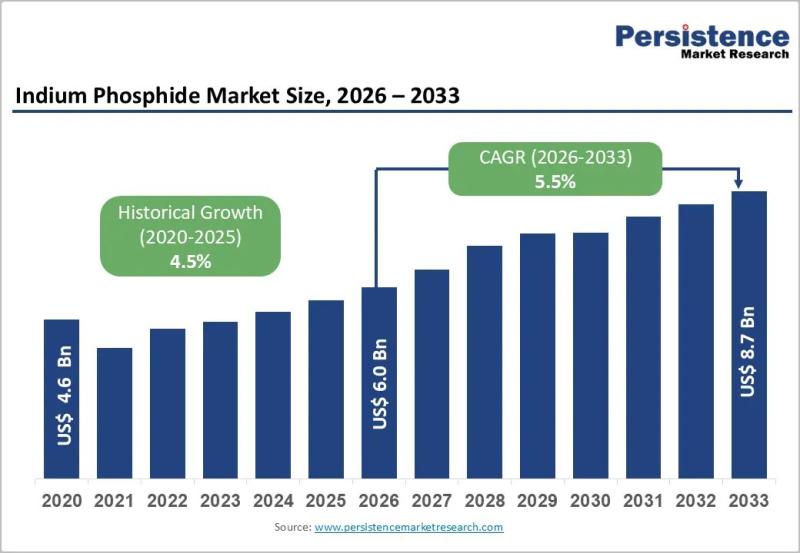

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

More Releases for Conveyor

YiFan Conveyor Strengthens Global Presence as a One-Stop Conveyor Solutions Prov …

Image: https://www.abnewswire.com/upload/2025/09/3d6a88fe91739b16779b2b9426bfdc46.jpg

Ningbo YiFan Conveyor Equipment Co., Ltd, a one-stop solution service provider for container loading and unloading conveyors, continues to make its mark as one of China's leading conveyor system manufacturers. Established in 2016 and headquartered in Ningbo, China, YiFan Conveyor has built a reputation for delivering innovative, reliable, and cost-effective conveyor solutions to industries across the globe.

Backed by an experienced and highly skilled technical R&D team, YiFan Conveyor independently…

Ningbo YiFan Conveyor Equipment Co., Ltd. Strengthens Global Reach with Comprehe …

Image: https://www.abnewswire.com/upload/2025/09/5faf1027de0534d1553f148f4ca4cf5a.jpg

Ningbo, China - September 5, 2025 - Ningbo YiFan Conveyor Equipment Co., Ltd., a China-based manufacturer of conveyor systems, continues to expand its role in industries worldwide by supplying a wide range of loading and unloading conveyor technologies. The company, headquartered in Ningbo, provides what it calls a "one-stop solution service," producing systems that are now used across logistics, warehousing, e-commerce, manufacturing, and other industrial sectors.

Founded in 2016, YiFan…

Belt Conveyor | Inclined Belt Conveyor | Flat Belt Conveyor - Technovision

General:

We specialize in manufacturing qualitative range of Belt Conveyor which find wide application in various fields to move diverse unit loads & bulk materials. Our conveyors are highly in demand in mining operation, foundries, bagasse handling in co-generation plants granaries, coal handling plants, bag handling in sugar godowns and packing industries. They are used in handling loads from one location to another within the process in line production. The Belt…

Loading Unloading Conveyor - Truck Loader Unloader Conveyor

Loading Unloading Conveyor

The Company is one of the front Runner in Manufacturing Material Handling Equipment and Truck Loader Conveyor in India With an ISO 9001-2015 Certification. The core focus of the company lies in superior quality and excellent customer services. Technovision Engineers Pvt. Ltd. Manufacturer & Supplier of a wide range of products which include Conveyor such as Truck Loader Conveyor, Loading Unloading Conveyors System etc.

General

We have leading specialization in manufacturing of Truck Loading Unloading Conveyor…

High Temperature Conveyor Market 2025 Business Opportunities with Key Players- L …

Reportsweb: Statistical Analysis for “High Temperature Conveyor Market” capacity, production, production value, cost/profit, supply/demand and import/export. The report will assist reader with better understanding and decision making.

“Global High Temperature Conveyor Market Analysis 2025” is a reliable business document for its targeted audiences such as manufacturers of high temperature conveyor, industry experts, industrial raw material suppliers and buyers, high temperature conveyor business authorities and end-users. It covers in-depth market analysis and…

Heat Resistant Conveyor Belt Market Size 2017 Dunlop Conveyor Belting, Savatech, …

Heat Resistant Conveyor Belt Market Research Report

A market study ” Global Heat Resistant Conveyor Belt Market ” examines the performance of the Heat Resistant Conveyor Belt market Size 2017. It encloses an in-depth Research of the Heat Resistant Conveyor Belt market state and the competitive landscape globally. This report analyzes the potential of Heat Resistant Conveyor Belt market in the present and the future prospects from various angles in…