Press release

Ammonia Manufacturing Plant Setup Report 2025: Cost and Raw Material Requirements

IMARC Group's "Ammonia Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" report provides a comprehensive guide on how to successfully set up an ammonia manufacturing plant. The report offers clarifications on various aspects, such as unit operations, raw material requirements, utility supply, infrastructural needs, machinery models, labour necessities, transportation timelines, packaging costs, etc.In addition to the operational aspects, the report also provides in-depth insights into ammonia manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful ammonia manufacturing unit.

Request a Sample Report: https://www.imarcgroup.com/ammonia-manufacturing-plant-project-report/requestsample

What is Ammonia?

Ammonia is a colorless gas with a pungent odor, composed of nitrogen and hydrogen, with the chemical formula NH3. It occurs naturally in the environment from the decomposition of organic matter and is also synthetically produced on a large scale for industrial applications. Ammonia is highly soluble in water, forming a solution known as ammonium hydroxide, which is commonly used in cleaning products. Its primary use is as a fertilizer in agriculture, where it plays a critical role in supplying nitrogen, an essential nutrient for plant growth. Additionally, ammonia serves as a building block for the manufacture of various chemicals, including explosives, plastics, dyes, and pharmaceuticals. Due to its ability to absorb heat, ammonia is also employed as a refrigerant in industrial refrigeration systems. Despite its widespread utility, ammonia is toxic in high concentrations, requiring careful handling and storage to ensure environmental and occupational safety.

Market Trend and Drivers of Ammonia:

The global ammonia market is primarily driven by its critical role in the agricultural sector, particularly as a key component in nitrogen-based fertilizers. With the growing demand for food due to increasing global population levels, the need for high-yield crops has surged, boosting the consumption of ammonia-based fertilizers such as urea, ammonium nitrate, and ammonium sulfate. Additionally, industrial applications in pharmaceuticals, textiles, and chemical manufacturing contribute to sustained market demand. Technological advancements in ammonia production, particularly the integration of low-carbon or green ammonia using renewable energy sources, are also reshaping the market landscape. The transition toward sustainable agricultural practices and decarbonization in energy-intensive industries has prompted investments in green ammonia, further expanding its application in energy storage and as a potential fuel. Furthermore, stringent environmental regulations are encouraging the development of cleaner ammonia production methods, enhancing its long-term viability. These factors collectively underpin the continued growth and diversification of the global ammonia market.

Buy Full Report: https://www.imarcgroup.com/checkout?id=7857&method=1911

Key Aspects to Setup an Ammonia Plant:

• Location to Setup Plant

• Market Research

• Plant Layout

• Construction and Infrastructure

• Equipment/Machinery Procurement

• Documentation and Licenses

• Cost Analysis

Requirements to Setup a Facility:

• Funds

• Machinery

• Lands

Types of Costs to Setup a Factory:

• Land, Location and Site Development Cost

• Plant Layout Cost

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Key Questions Answered in the Report:

• How has the ammonia market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global ammonia market?

• What is the regional breakup of the global ammonia market?

• What are the price trends of various feedstocks in the ammonia industry?

• What is the structure of the ammonia industry and who are the key players?

• What are the various unit operations involved in an ammonia manufacturing plant?

• What is the total size of land required for setting up an ammonia manufacturing plant?

• What is the layout of an ammonia manufacturing plant?

• What are the machinery requirements for setting up an ammonia manufacturing plant?

• What are the raw material requirements for setting up an ammonia manufacturing plant?

• And more...

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7857&flag=C

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ammonia Manufacturing Plant Setup Report 2025: Cost and Raw Material Requirements here

News-ID: 4000623 • Views: …

More Releases from IMARC Group

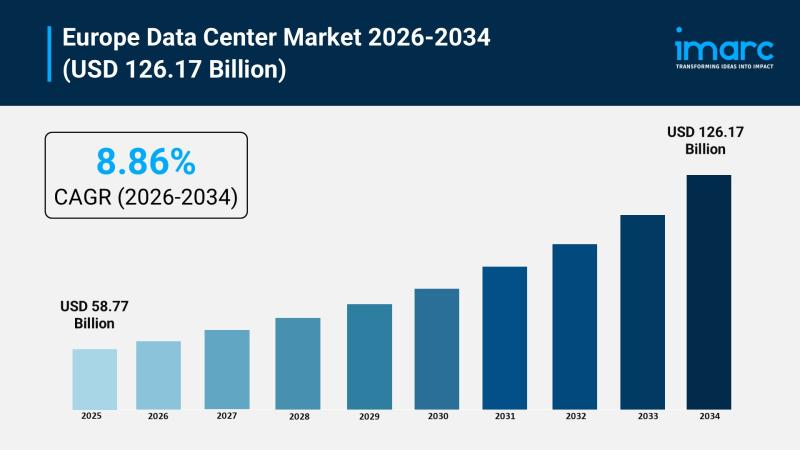

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

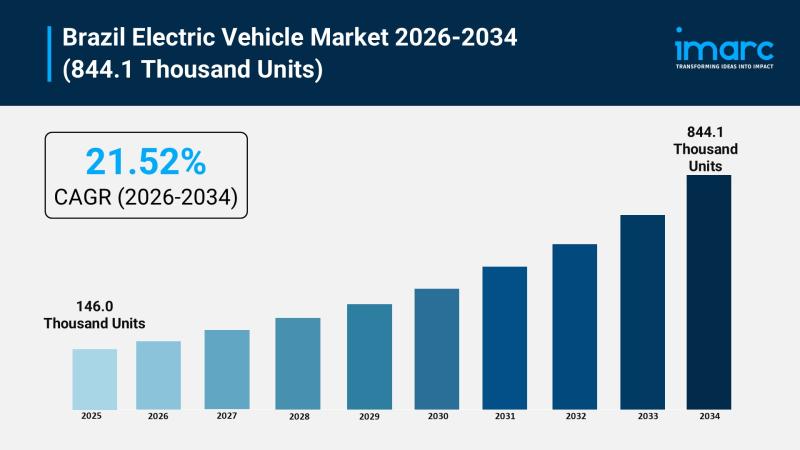

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…