Press release

Pressure Cooker Manufacturing Plant Setup Report 2025: Unit Operations, Machinery Requirements and Cost Analysis

Setting up a pressure cooker manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Pressure Cooker Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a pressure cooker manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

A pressure cooker is a kitchen tool that cooks food quickly using steam pressure. It has a sealed pot with a locking lid that keeps steam from escaping. This steam raises the internal pressure, allowing temperatures to exceed the normal boiling point of water. As a result, food cooks faster than with traditional methods, which is great for busy households. They work well for tough cuts of meat, grains, and legumes, making them tender and flavorful in less time. With more people interested in home cooking, pressure cookers have become popular. They save time, keep nutrients, and boost flavors, making them a must-have in many kitchens.

The pressure cooker industry is growing fast, and this rise is due to more people interested in home cooking and healthier meals. As health awareness increases, many turn to pressure cookers for quick cooking that keeps nutrients intact. The demand for electric pressure cookers is also rising. These cookers offer features like slow cooking, sautéing, and air frying. They meet modern consumers' needs for efficiency and versatility. Technological advancements greatly impact the industry. Smart pressure cookers now have Wi-Fi or Bluetooth. Users can control cooking settings remotely with smartphone apps. This enhances the cooking experience. Sustainability is another important trend. Manufacturers are using eco-friendly materials and energy-efficient designs to attract environmentally conscious buyers. Geographic expansion is notable, especially in emerging markets. Urbanization and busy lifestyles create a demand for quick and easy cooking solutions. Overall, the pressure cooker industry is set for continued growth. This growth comes from changing consumer preferences, new technologies, and a focus on health and sustainability.

Request for a Sample Report: https://www.imarcgroup.com/pressure-cooker-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up a Pressure Cooker Plant.

1. Market Analysis

The report provides insights into the landscape of the pressure cooker industry at the global level. The report also provides a segment-wise and region-wise breakup of the global pressure cooker industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of pressure cooker, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the pressure cooker manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy Now: https://www.imarcgroup.com/checkout?id=30693&method=1911

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for the pressure cooker manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for pressure cooker production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=30693&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a pressure cooker manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pressure Cooker Manufacturing Plant Setup Report 2025: Unit Operations, Machinery Requirements and Cost Analysis here

News-ID: 4000387 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

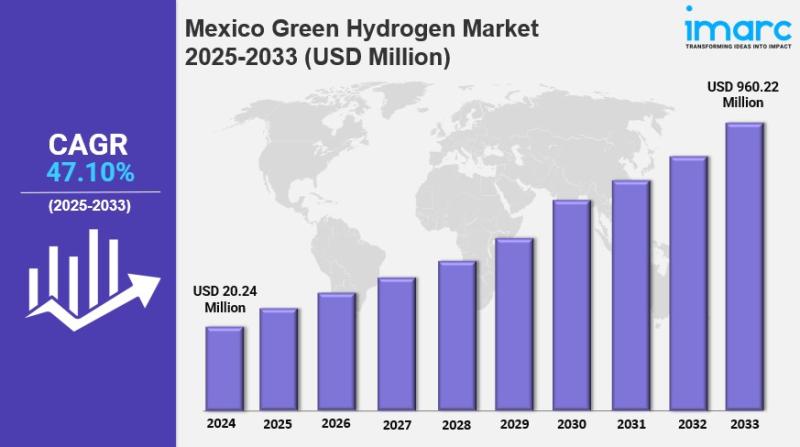

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Pressure

Benefits of Pressure Washing With Cen-Cal Pressure Pros

Fresno, CA - Over time, a property's exterior surfaces will collect debris, causing them to lose their visual appeal. This negative effect will become more and more noticeable over time, eventually causing property owners to seek out the best solution. In most cases, pressure washing [https://www.cencalpressurepros.com/pressure-washing-company-in-fresno-ca/] is the go-to answer to dirty exterior surfaces. Pressure washing uses high-pressure water to disturb and remove debris from these surfaces. This process has…

Ensuring Pressure Washing Safety With D4S Pressure Washing

Tampa, FL - Pressure washing [https://www.d4spressurewashing.com/pressure-washing-company-in-tampa-fl/] is an effective way of restoring a property's exterior surfaces. The process makes them cleaner, and as a result, more visually appealing. However, pressure washing does not come without its fair share of challenges. For instance, pressure washing uses highly pressurized water, and handling this force can cause significant harm or damage if the correct precautions are not taken. Learn what precautions to take…

How Midland Pressure Washing Conquers Pressure Washing Challenges

Leawood, KS - Pressure washing [https://www.midlandpressurewash.com/pressure-washing-company-in-leawood-ks/] does not go the exact same way every single time. In fact, this versatile process is used to clean a variety of different surfaces, and the precise details of pressure washing can be customized to match the job. With some knowledge of the demands of every surface that needs to be cleaned, residential and commercial property owners can harness the power of pressure washing…

Pressure Washing vs. Soft Washing With Riptide Pressure Washing

Wilmington, NC - The exterior surfaces of any property will become dirty over time. When this occurs, the owner of the property may become interested in cleaning them. However, the best way to accomplish this work may not be immediately clear. Should exterior surfaces be pressure washed, or soft washed? And what precisely is the difference between these two options? Riptide Pressure Washing [https://www.riptide-wash.com/] proudly provides pressure washing [https://www.riptide-wash.com/pressure-washing-company-in-wilmington-nc/] and…

DIY Pressure Washing Versus Professional Pressure Washing

West Hartford, CT - When a property's exterior surfaces become coated with dirt and debris, the property owner may decide the surfaces need to be pressure washed. At this point, the property owner has to make an important decision. Will they attempt to clean those exterior surfaces on their own? Or will they reach out to a professional business for the help they need? Both of these paths are valid…

Precision Under Pressure: Trends in Fluid Pressure Sensors

The Business Research Company recently released a comprehensive report on the Global Fluid Pressure Sensors Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, the fluid pressure…