Press release

What is CO2 Laser Cutting? And how does it work on fabric?

Are you curious about how CO2 laser cutting can transform fabric production with precision and efficiency? Whether you're a hobbyist, designer, or manufacturer, understanding the basics of CO2 laser cutting is essential for unlocking its potential. In this guide, we'll break down how CO2 laser cutting works, its benefits for fabric cutting, and why it's a game-changer for the textile industry. By the end, you'll have a clear understanding of the process and how to leverage it for your projects.The finding the best focal length of CO2 laser plays a significant role in the quality of cuts, particularly when working with laser cutting fabric. A shorter focal length (1.5" to 2.5") is ideal for intricate designs on thin fabrics, while a longer focal length (3" to 5") is better for thicker materials. The right focal length ensures a focused beam, reducing charring and improving edge quality. Experiment with different lengths to find the perfect setup for your fabric cutting needs.

https://www.mimowork.com/laser/co2-laser-lens-focal-length

1. What is CO2 Laser Cutting?

CO2 laser cutting is a technology that uses a high-powered laser beam generated by a carbon dioxide gas mixture to cut, engrave, or etch materials. When it comes to fabric, this method offers unmatched precision, speed, and versatility. The laser beam is directed by mirrors and focused through a lens, creating a concentrated point of energy that vaporizes the material along a pre-programmed path.

2. How Does It Work on Fabric?

Laser Generation: The CO2 laser tube emits an infrared beam, which is then reflected and focused onto the fabric's surface.

Material Interaction: The laser's heat energy melts or vaporizes the fabric fibers along the cutting path.

Edge Sealing: One of the unique advantages of laser cutting fabric is that it simultaneously seals the edges, preventing fraying-a common issue with traditional cutting methods.

Precision and Detail: The laser can cut intricate patterns, curves, and fine details with minimal kerf (material loss), making it ideal for delicate fabrics like silk, polyester, and cotton.

3. Benefits of CO2 Laser Cutting for Fabric

Precision: Achieve intricate designs and clean edges that are impossible with manual cutting.

Speed: Cut multiple layers of fabric in seconds, significantly reducing production time.

Versatility: Works on a wide range of fabrics, from natural fibers to synthetics.

Automation: Compatible with CAD software, allowing for repeatable and scalable production.

Eco-Friendly: Reduces material waste and eliminates the need for additional edge-sealing processes.

4. Real-World Applications

Fashion Design: Create intricate lace patterns, custom appliques, and perfectly tailored pieces.

Home Textiles: Produce precise cuts for curtains, upholstery, and decorative fabrics.

Industrial Use: Manufacture technical textiles, such as automotive interiors or medical fabrics, with high accuracy.

Now that you understand the basics of how CO2 laser cutting works and its advantages for fabric, you might be wondering how to get started or optimize your cutting process. Let's explore some practical tips and considerations for beginners.

Laser cutter for sublimated fabric have revolutionized the way sublimated fabrics are processed for sportswear and clothing. By using precise laser technology, manufacturers can achieve clean, intricate cuts without fraying edges, ensuring high-quality finishes for athletic apparel and fashion garments. This method is particularly beneficial for sublimated fabrics, as it preserves the vibrant prints and patterns during the cutting process. Whether you're creating custom jerseys, activewear, or trendy clothing, laser cutting offers unmatched precision and efficiency. Integrating a laser cutter for sublimated fabric into your production line can elevate your designs and streamline your workflow.

https://www.mimowork.com/sublimation-fabrics-laser-cutter/

Practical Tips for Beginners

1. Choose the Right Fabric

Not all fabrics react the same way to laser cutting. Natural fibers like cotton and silk cut cleanly, while synthetics like polyester may melt or discolor. Always test on a small sample before full-scale production.

2. Optimize Settings

Adjust the laser's power, speed, and focus to match the fabric type and thickness. Lower power and higher speed are ideal for delicate fabrics, while thicker materials may require more power.

3. Use Vector Files

Design your patterns in vector format (e.g., SVG or DXF) for precise cutting paths. Most laser cutting software supports these file types.

4. Ensure Proper Ventilation

Laser cutting can produce fumes, especially with synthetic fabrics. Use an exhaust system or work in a well-ventilated area to maintain safety.

5. Maintain Your Equipment

Regularly clean the laser lens and mirrors to ensure optimal performance. A well-maintained machine delivers consistent results and extends its lifespan.

Conclusion

CO2 laser cutting is a revolutionary technology that combines precision, speed, and versatility, making it an invaluable tool for fabric cutting. Whether you're creating custom designs or scaling up production, understanding the process and its benefits can help you achieve professional results. By following the tips outlined above, you'll be well on your way to mastering CO2 laser cutting for fabric.

Ready to take your fabric projects to the next level? Explore CO2 laser cutting today and experience the difference it can make!

Media Contact

Company Name: Mimowork

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-is-co2-laser-cutting-and-how-does-it-work-on-fabric]

Country: China

Website: https://www.mimowork.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What is CO2 Laser Cutting? And how does it work on fabric? here

News-ID: 3995176 • Views: …

More Releases from ABNewswire

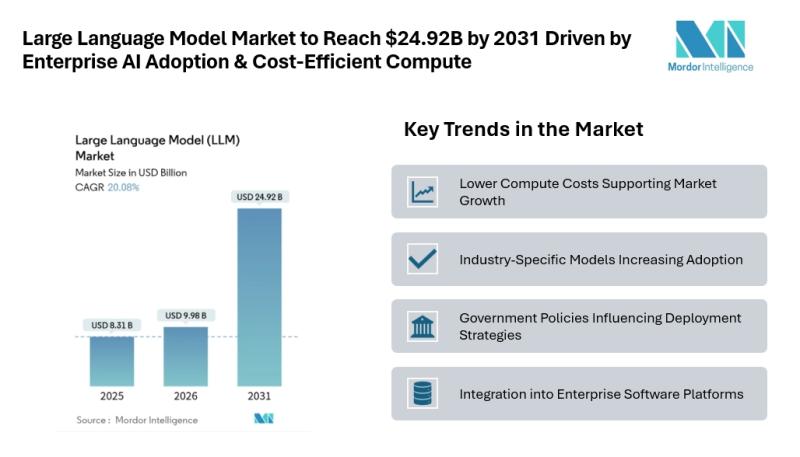

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

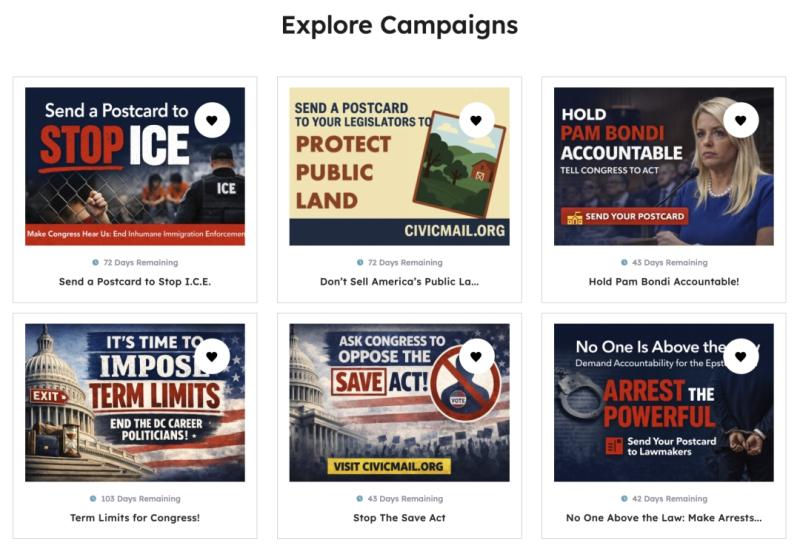

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for CO2

Practical Tips for CO2 Laser Cutting Fabrics and Benefits of CO2 Laser Cutting f …

Best Fabrics for CO2 Laser Cutting: What You Need to Know

Are you wondering which fabrics work best with CO2 laser cutting? Whether you're a fashion designer, hobbyist, or manufacturer, choosing the right fabric can make or break your project. In this guide, we'll explore the best fabrics for CO2 laser cutting, their unique properties, and practical tips to achieve flawless results. By the end, you'll have the knowledge to select…

Global CO2 Injector(CO2 Bubbler) Market Expected to Witness a Sustainable Growth …

LP INFORMATION recently released a research report on the CO2 Injector(CO2 Bubbler) market analysis, which studies the CO2 Injector(CO2 Bubbler)'s industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global "CO2 Injector(CO2 Bubbler) Market 2020-2025" Research Report categorizes the global CO2 Injector(CO2 Bubbler) market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players…

Bacteria as CO2 recycling powerhouse

E. coli can live and feed on formate & methanol:

Scientists from the Max Planck Institute (Germany) have reached a significant breakthrough presented in their recent Nature Chemical Biology publication. Their research for EU project eForFuel has redesigned the model biotechnological bacteria Escherichia coli (E. coli) to live and feed on methanol and formate: a possibility that serves as a stepping stone towards future endeavors aiming at recycling CO2 into various…

Global Transcritical CO2 Market |

Data Bridge market Research has released a new report on Global Transcritical CO2 Market which incorporates a thorough assessment of overall Global Transcritical CO2 Market The report provides a detailed competitive analysis which includes the profiles of key market players and organizations and their working strategies. The report consists of essential data and information about the concerned Global Refinished Paint Market. For better understanding complex Global Transcritical CO2 Market data…

Beer CO2 Regulator Market Size Detail Analysis focusing on Key Players like Tapr …

Scope of the Report:

The worldwide Beer CO2 Regulator Market is expected to grow at a CAGR of roughly over the next five years, will reach million US$ in 2024, from million US$ in 2019, according to a new GIR (Global Info Research) study.

This report focuses on the Beer CO2 Regulator in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the…

Global Beer CO2 Regulator Market | 2018 Key Vendors: Taprite, Titan Controls, Pr …

Qyresearchreports include new market research report “Global Beer CO2 Regulator Market Research Report 2018” to its huge collection of research reports.

This report on the global Beer CO2 Regulator market is based upon thorough study conducted by some of the professional and expert analysts of the industry. This report emphasizes on several factors including government regulations that are influencing growth of the market positively or negatively. The report explains challenges, opportunities,…