Press release

Fiberglass Reinforced Plastic (FRP) Pipe manufacturing Plant: Setup Cost, Machinery and Raw Materials

Setting up a fiberglass reinforced plastic (FRP) pipe manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Fiberglass Reinforced Plastic (FRP) Pipe Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a fiberglass reinforced plastic (FRP) pipe manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/fiberglass-reinforced-plastic-pipe-manufacturing-plant-project-report/requestsample

Fiberglass Reinforced Plastic (FRP) pipe is a composite material pipe manufactured by combining a polymer resin matrix with glass fiber reinforcement. This combination offers a high strength-to-weight ratio, corrosion resistance, and excellent durability in aggressive environments. FRP pipes are engineered to withstand a wide range of temperatures and pressures, making them ideal for applications in industries such as chemical processing, oil and gas, water treatment, and marine. The material is resistant to both internal and external chemical attacks, reducing maintenance costs and extending operational life. Additionally, FRP pipes are lightweight, facilitating easier handling and installation compared to traditional metal or concrete alternatives, which contributes to lower transportation and labor costs in both industrial and infrastructure projects.

The Fiberglass Reinforced Plastic (FRP) pipe market is primarily driven by increasing demand for corrosion-resistant and durable piping solutions across various end-use industries. Rapid industrialization, especially in emerging economies, has led to growing investments in water and wastewater infrastructure, chemical processing, and oil and gas sectors-all of which favor FRP due to its low maintenance and long service life. Additionally, the shift towards lightweight and non-metallic materials to reduce transportation and installation costs is boosting market adoption. Environmental regulations encouraging the use of sustainable, non-corrosive materials further propel market growth. Technological advancements in composite manufacturing and a rising focus on infrastructure modernization globally also contribute significantly to the expanding demand for FRP piping systems.

Buy Full Report: https://www.imarcgroup.com/checkout?id=15718&method=1911

Key Steps Required to Set Up a Fiberglass Reinforced Plastic (FRP) Pipe Plant

1. Market Analysis

The report provides insights into the landscape of the fiberglass reinforced plastic (FRP) pipe industry at the global level. The report also provides a segment-wise and region-wise breakup of the global fiberglass reinforced plastic (FRP) pipe industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of fiberglass reinforced plastic (FRP) pipe, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the fiberglass reinforced plastic (FRP) pipe manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for fiberglass reinforced plastic (FRP) pipe manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for fiberglass reinforced plastic (FRP) pipe production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a fiberglass reinforced plastic (FRP) pipe manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=15718&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fiberglass Reinforced Plastic (FRP) Pipe manufacturing Plant: Setup Cost, Machinery and Raw Materials here

News-ID: 3971115 • Views: …

More Releases from IMARC Group

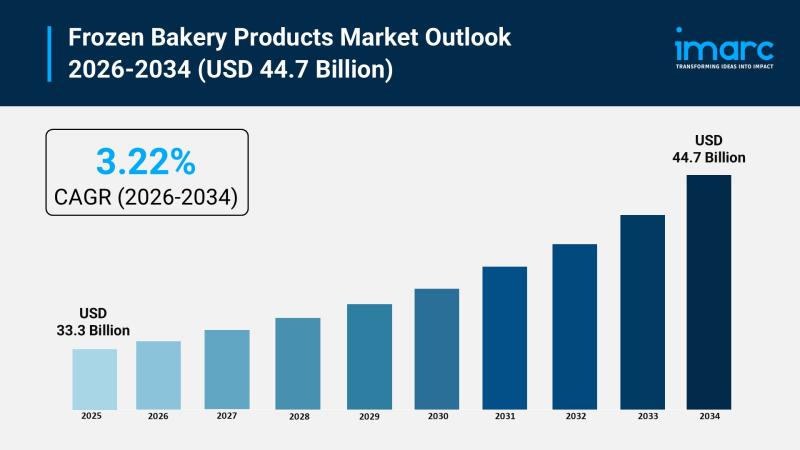

Frozen Bakery Products Market Size to Hit USD 44.7 Billion by 2034 | With a 3.22 …

Market Overview:

According to IMARC Group's latest research publication, "Frozen Bakery Products Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global frozen bakery products market size reached USD 33.3 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 44.7 Billion by 2034, exhibiting a growth rate (CAGR) of 3.22% during 2026-2034.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth…

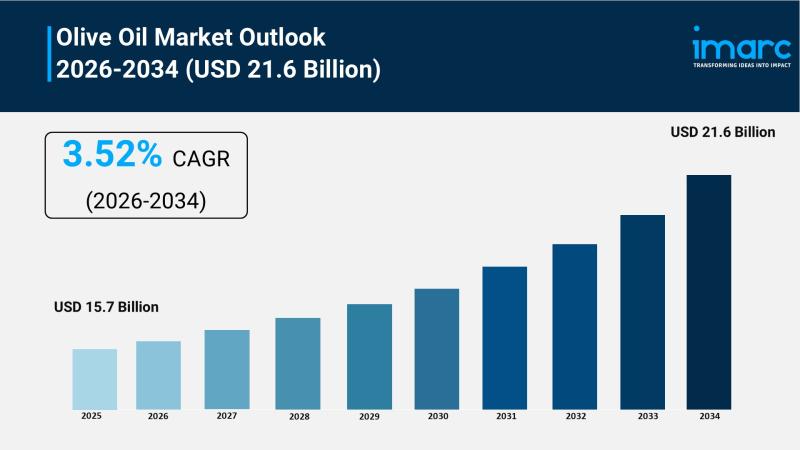

Olive Oil Market to Reach USD 21.6 Billion by 2034, Growing at a CAGR of 3.52%

Market Overview:

The Olive Oil Market is experiencing steady expansion, driven by Rising Health and Wellness Trends, Increasing Culinary Diversity and Authenticity and Sustainability and Organic Preferences. According to IMARC Group's latest research publication, "Olive Oil Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global olive oil market size was valued at USD 15.7 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD…

Bioethanol Production Plant Cost 2026: Raw Materials & Pricing Trends

Setting up a Bioethanol Production Plant positions investors in one of the most stable and essential segments of the renewable energy and biofuel value chain, backed by sustained global growth driven by rising demand for clean-burning renewable fuels, increasing adoption of sustainable energy alternatives across automotive, pharmaceutical, and chemical industries, accelerating decarbonization requirements across global energy systems, and the dual-benefit advantages of reducing carbon emissions while simultaneously supporting rural agricultural…

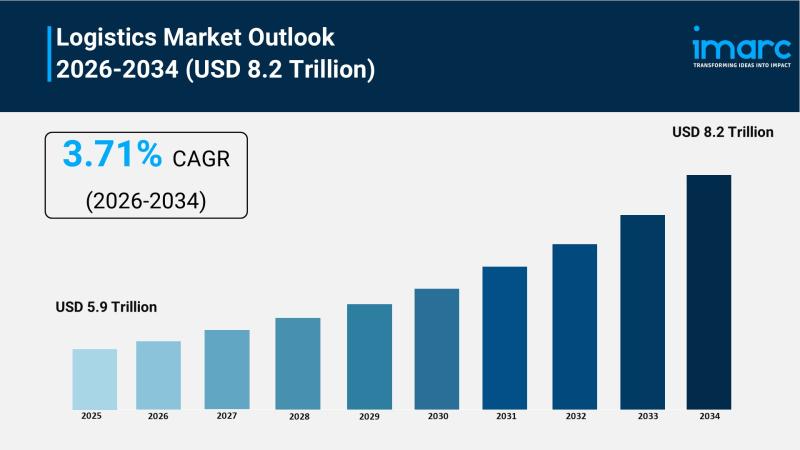

Logistics Market to Reach USD 8.2 Trillion by 2034, Growing at a CAGR of 3.71%

Market Overview:

The Logistics Market is experiencing steady expansion, driven by E-commerce Growth, Technological Advancements, and Globalization of Trade. According to IMARC Group's latest research publication, "Logistics Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global logistics market size was valued at USD 5.9 Trillion in 2025. Looking forward, the industry is projected to reach USD 8.2 Trillion by 2034, exhibiting a CAGR of 3.71% during 2026-2034.

This…

More Releases for FRP

FRP Rebar Market Set to Soar to $1361 Million by 2031 with 6.7% CAGR | Aslan FRP …

Report Description -

QYResearch latest report 'FRP Rebar Market 2025 Report' provides a comprehensive analysis of the industry with market insights will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. Finally, this will increase the return rate and strengthen the competitive advantage within. Since it's a personalised market report, the services are catered to the particular difficulty. The correct methodology…

Fiber Reinforced Plastics (FRP) Sales Market Size Analysis by Application, Type, …

According to Market Research Intellect, the global Fiber Reinforced Plastics (FRP) Sales market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The market for Fiber Reinforced Plastics (FRP) has been steadily growing due to rising demand…

FRP Cable Tray Market Size and Forecast

FRP Cable Tray Market size was valued at USD 1.5 Billion in 2022 and is projected to reach USD 2.8 Billion by 2030, growing at a CAGR of 8.2% from 2024 to 2030.

FRP Cable Tray Market Outlook and Investment Analysis

What is the current outlook for the FRP Cable Tray Market?

The FRP Cable Tray market is experiencing strong growth due to its increasing demand across various industries such as construction, electrical,…

FRP Rebar Market Growth Dynamics 2025-2032

The Fiber Reinforced Polymer (FRP) Rebar market has emerged as a critical player in the construction sector, offering innovative solutions for reinforcing concrete structures. With its lightweight, high tensile strength, and corrosion resistance, FRP Rebar is gaining traction in various applications, including road building, bridges, and underground construction. The market is characterized by a growing demand for sustainable construction materials, which is driving the adoption of FRP Rebar as a…

Key Trend Reshaping the FRP Tank Market in 2025: Product Innovation In The FRP T …

What combination of drivers is leading to accelerated growth in the frp tank market?

The growth of FRP tanks is anticipated to be driven by the escalating need for oil and gas storage solutions. Storage systems for oil and gas incorporate terminals or tanks that keep the produced oil and gas either above or underground. The oil and gas sector utilizes FRP tanks to hold bulk quantities of fluids at various…

FRP Pole Market Size, Share | Trend 2022

The global frp pole market size was valued at USD 328.1 million in 2021 and is expected to grow at a CAGR of 5.8% during the forecast period 2022 to 2028. FRP Pole (Fiber Reinforced Polymer Pole) is a type of composite material that is made by combining fibers such as carbon, fiberglass, or aramid with a polymer matrix. These poles are lightweight, strong, and highly durable, which makes them…