Press release

How to Prevent Copper-Free Holes in High Aspect Ratio PCBs: Key Insights for PCB Manufacturing

Understanding the Importance of Hole Size to Thickness Ratio in PCB Manufacturing [https://www.richpcba.com/pcb-assembly-service/]In PCB manufacturing, the hole size to thickness ratio, also known as the aspect ratio, is a critical factor that influences the quality of hole plating. This ratio is calculated by dividing the PCB's thickness by the hole diameter, often referred to as the length-to-diameter ratio (L/D).

For instance, if a PCB's thickness is 1.60 mm and the hole diameter is 0.2 mm, the aspect ratio is 8:1. Lower aspect ratios indicate thinner boards with larger holes, which typically result in better plating results due to more even ion distribution during the electroplating process.

However, high aspect ratio PCBs-those with thin boards and small holes-pose significant challenges during the electroplating process, leading to defects such as copper-free holes (also known as "blind vias" or "voids") and poor quality plating.

What Causes Copper-Free Holes in High Aspect Ratio PCBs?

* Micro-Bubbles and Blockage - In the traditional direct current (DC) electroplating process, the electroplating solution may trap micro-bubbles in the hole, preventing the copper from evenly plating the hole walls. These bubbles can block the flow of copper, resulting in areas with insufficient copper deposition.

* Poor Cleaning During Pre-Treatment - If the PCB isn't properly cleaned before plating, contaminants or residues may remain inside the holes. This prevents the copper from adhering to the hole walls, creating voids and weak spots.

* Drill Defects - When drilling high aspect ratio holes, if the drill bit isn't sharp enough, it can cause issues with the hole's internal surface. Instead of smoothly removing the material, the drill bit might pull and tear resin or fiberglass, leaving rough surfaces. This can hinder the plating process and lead to poor copper adhesion.

[https://www.richpcba.com/pcb-assembly-service/]

How High Aspect Ratio Affects Plating Quality

For high aspect ratio PCBs (e.g., 14:1, 16:1, or even 20:1), the plating process becomes more challenging. The electroplating solution struggles to deposit copper uniformly, especially in the inner regions of the holes, which results in a dog-bone effect. This means the hole's top becomes wider while the lower part remains underplated.

Additionally, the hole's electrical current density varies across the hole's surface. At the entrance of the hole, the current density is higher, while in the deeper parts, it's lower. This uneven distribution leads to poor plating in the lower parts of the hole, contributing to the formation of copper-free holes.

Advanced Solutions to Prevent Copper-Free Holes in High Aspect Ratio PCBs

To avoid these issues, modern PCB manufacturing factories are turning to pulse plating technology, which overcomes many of the limitations of traditional DC electroplating.

Pulse Plating for Uniform Copper Deposition

Pulse plating uses alternating current with controlled pulses to increase copper deposition efficiency. Unlike conventional DC plating, pulse plating enhances the ion movement inside the hole, allowing for more uniform copper deposition across the hole, both at the entrance and deeper regions. This results in better plating quality and avoids the formation of copper-free holes.

Additionally, pulse plating ensures that copper is evenly deposited without significantly increasing the copper thickness on the board surface, maintaining the integrity of high-density circuits, fine lines, and precision impedance.

Image: https://ecdn6.globalso.com/upload/p/730/image_news/2025-02/21286b63ef4e40846cd7760b8c7343e7.png

Other Strategies

* Improved Drilling Techniques - Using high-precision drills can ensure smoother and cleaner holes, improving the surface quality and ensuring that the plating process is more effective.

* Optimized Pre-Treatment - Thorough cleaning and treatment of PCB holes can ensure better copper adhesion. Using chemical etching or plasma cleaning techniques can eliminate any contaminants and improve the quality of the hole wall, leading to better plating results.

* Use of Advanced Plating Equipment - Modern PCB factories utilize equipment that is specifically designed to handle high aspect ratio PCBs. This includes improved electroplating tanks, advanced solution filtration systems, and better current control mechanisms.

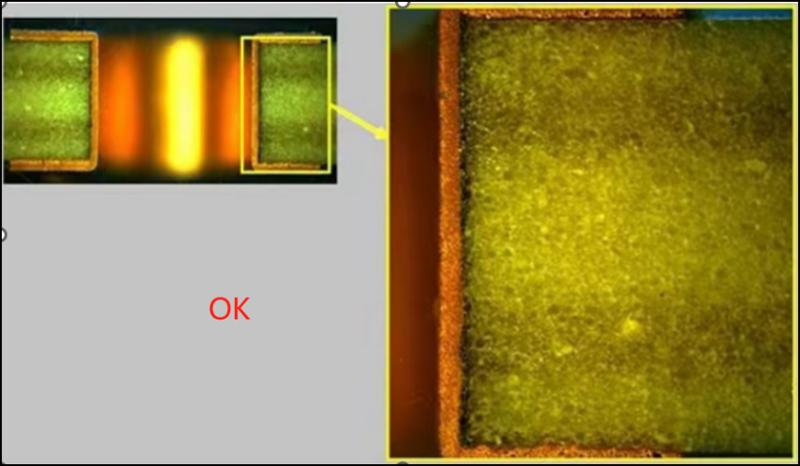

How to make the hole in the picture below?

Solution: Richfulljoy's pulsed VCP can avoid the frequent occurrence of excessive pits and holes in DC plating. High current density plating efficiency is high, and under the pulse plating system, it can make the inside and outside of the hole very good. The coating distribution effect can be achieved, and the surface copper does not increase, and the surface copper does not increase, and the thin circuit and high-precision impedance can be guaranteed.

Image: https://ecdn6.globalso.com/upload/p/730/image_news/2025-02/d26d3487e75f82e0193e08a8e1909ba1.png

Improving Quality in High Aspect Ratio PCB Manufacturing

In high aspect ratio PCB manufacturing, preventing copper-free holes is crucial for maintaining product integrity and performance. By understanding the challenges associated with plating in high aspect ratio designs and adopting advanced technologies like pulse plating, PCB manufacturers can ensure consistent and reliable plating quality.

If you're involved in PCB fabrication or working with PCB manufacturing factories, it's important to be aware of these techniques and work with manufacturers who have the expertise to handle high aspect ratio PCBs with the latest technology.

Media Contact

Company Name: richpcba

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=how-to-prevent-copperfree-holes-in-high-aspect-ratio-pcbs-key-insights-for-pcb-manufacturing]

Country: China

Website: https://www.richpcba.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Prevent Copper-Free Holes in High Aspect Ratio PCBs: Key Insights for PCB Manufacturing here

News-ID: 3966137 • Views: …

More Releases from ABNewswire

Post-Construction Cleaning Demand Rises Among Miami Renovators as The Prime Clea …

Miami homeowners and contractors are driving increased demand for professional post-construction cleaning services, with The Prime Cleaner reporting significant growth in this specialty category across South Florida.

MIAMI, FL - Demand for professional post-construction cleaning services is rising across Miami as homeowners complete renovations and contractors seek reliable cleaning partners for new builds. The Prime Cleaner has expanded its post-construction cleaning services [https://www.theprimecleaner.com/service/post-construction-cleaning] to meet the growing need.

Miami's construction and renovation…

Extending the Invisible Cord: Why Bluetooth Repeaters Are Essential for Seamless …

We live in a wireless world. Our headphones, keyboards, speakers, and even our lightbulbs connect via Bluetooth, freeing us from the tangle of cables. Yet, despite its convenience, Bluetooth has a wellknown limitation: range. The connection between a device and its source-whether it's a phone streaming music or a sensor reporting data-can stretch only so far before it stutters and drops. For homes, offices, and industrial facilities, these dead zones…

Beyond GPS: How Bluetooth Beacons Are Bridging the Gap Between Digital and Physi …

In an era dominated by GPS, it is easy to assume we have solved the problem of location tracking. We can navigate bustling cities, track lost phones, and find the nearest coffee shop with pinpoint accuracy-provided we are outside. But the moment we step indoors, the satellite signals fade, leaving a blind spot in our connected experiences.

This is where a small, unassuming piece of technology is making a massive impact:…

ECI Jewelers Introduces Streamlined Selling Experience with Same-Day Offers and …

ECI Jewelers has enhanced its luxury watch and jewelry buying service with same-day market-based offers and instant payment options for sellers nationwide. The concierge-style approach includes free valuations, full insurance coverage during transit, and expert assessment from the company's New York City Diamond District location, simplifying the selling process for owners of premium timepieces from brands like Rolex, Patek Philippe, and Audemars Piguet.

Elegant Creations Inc, operating as ECI Jewelers, has…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…