Press release

Thin Film Deposition Equipment Market Poised for 9.4% CAGR Growth, Surpassing USD 70 Billion by 2031

The global thin film deposition equipment market, valued at USD 31.2 billion in 2022, is forecast to reach an impressive USD 70.0 billion by the end of 2031, growing at a compound annual growth rate (CAGR) of 9.4% over the period 2023-2031. This robust growth trajectory is driven by a surge in demand across the microelectronics, flexible electronics, and solar cell sectors, alongside continuous technological advancements that are redefining manufacturing paradigms across industries.Market Overview

The thin film deposition equipment market is witnessing significant transformation, powered by rapid advancements in microelectronics and renewable energy technologies. At its core, thin film deposition involves depositing a very fine layer of material onto a substrate, employing techniques such as Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and Atomic Layer Deposition (ALD). These processes are critical in the fabrication of integrated circuits, solar cells, optical coatings, and numerous other applications. The increasing complexity of electronic devices and the miniaturization trend have fueled demand for higher precision and efficiency in deposition techniques, making this market an attractive opportunity for both established and emerging players.

Explore the highlights and essential data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=84535

Key Players and Industry Leaders

The market is highly fragmented and characterized by fierce competition among several industry giants and innovative startups. Prominent companies such as AJA International, Inc., Blue Wave Semiconductors, Inc., Canon ANELVA Corporation, CVD Equipment Corporation, Intevac, Inc., Kenosistec Sr, Lam Research Corporation, Plasma-Therm LLC, Plassys Bestek, PVD Products, Inc., Samco, Inc., and Singulus Technologies AG have established themselves as leaders through continuous product innovation, strategic mergers and acquisitions, and expanded global footprints. Their commitment to research and development has been pivotal in introducing new techniques that enhance precision while lowering manufacturing costs.

Recent Developments

Recent strategic moves have further solidified market positions for leading players:

• Lam Research Corporation recently inaugurated a state-of-the-art research and development facility in India. This new center aims to localize design processes, reduce dependency on overseas operations, and foster closer collaborations with local semiconductor manufacturers.

• Plasma-Therm LLC expanded its operations in Europe by opening a Specialty Process Engineering Group plant in Somerset, England, facilitating better service for customers in the U.K. and Ireland.

These developments highlight a global trend where companies are investing in localized production and R&D to meet the specific demands of regional markets while maintaining a competitive edge in innovation and efficiency.

Market Drivers & Trends

Several key factors are fueling the expansion of the thin film deposition equipment market:

• Rising Demand for Microelectronics and Flexible Electronics:

The ongoing miniaturization of electronic components and the growing popularity of flexible electronic devices, such as foldable smartphones and bendable displays, are driving demand for highly precise and durable thin film coatings. The enhanced performance of microelectronics is directly linked to the ability to create thinner, more efficient films using advanced deposition techniques.

• Surge in Solar Cell Applications:

Renewable energy, particularly solar energy, is experiencing unprecedented growth. The global push for sustainable energy sources is boosting investment in solar cell technologies, where thin film deposition plays a vital role in manufacturing cost-effective, high-efficiency solar panels. Techniques such as PECVD and sputtering are integral in the production of a-Si and CIGS solar cells, respectively, which are both lightweight and flexible.

• Technological Advancements in Deposition Techniques:

Innovations such as atomic layer deposition (ALD) are enabling the production of ultra-thin films with unparalleled uniformity and conformality. These advancements not only drive down costs but also open new avenues for applications in semiconductor manufacturing, data storage, and precision optics.

• Environmental and Efficiency Benefits of PVD:

The physical vapor deposition (PVD) segment, widely used in semiconductor manufacturing and solar cell production, is particularly attractive due to its environmentally friendly nature. PVD processes generate minimal waste and require lower energy consumption compared to other methods, aligning well with global sustainability goals.

Market Restraints & Challenges

Despite robust growth prospects, the thin film deposition equipment market faces several challenges:

• High Capital Investment:

The advanced machinery required for thin film deposition is capital intensive, posing significant financial challenges for new entrants and smaller players.

• Technological Complexity:

Maintaining precision and consistency in deposition processes requires cutting-edge technology and expertise, which may limit market penetration in developing regions.

• Supply Chain Disruptions:

Fluctuations in the supply chain, particularly for high-purity materials and specialized components, can lead to production delays and increased operational costs.

• Regulatory and Environmental Compliance:

Stringent environmental regulations concerning the use and disposal of chemicals in CVD and other deposition processes could impact operational flexibility and increase compliance costs.

Visit our report for a deep dive into key insights and conclusions - https://www.transparencymarketresearch.com/thin-film-deposition-equipment-market.html

Market Segmentation

The global thin film deposition equipment market is segmented on several parameters:

• By Type:

o Physical Vapor Deposition (PVD): Dominates the market with widespread applications in semiconductors, data storage, and solar cell production.

o Chemical Vapor Deposition (CVD): Expected to witness rapid growth, particularly in high-performance electronic device production.

o Atomic Layer Deposition (ALD): Gaining traction for applications requiring ultra-thin and conformal coatings.

• By Application:

o Solar Cells

o Semiconductor Lasers

o Hard Disk Drives

o Precision Optics

o LED Displays

o Memory Devices

o Discrete & Power Devices

o Sensors & Transducers

o Transistors

o Others (including optical filters and eyeglasses)

• By Industry Vertical:

o IT & Telecommunication

o Semiconductor & Electronics

o Energy & Utility

o Consumer Electronics

o Automotive

o Healthcare

o Others (aerospace & defense, research & academia)

• By End-Use:

o Integrated Device Manufacturers (IDMs)

o Foundries

Regional Insights

The Asia Pacific region holds the largest market share, accounting for approximately 42.0% of the global market in 2022. This dominance is primarily due to the high demand for miniaturized electronic devices and significant investments in solar cell technologies in developing countries. Major semiconductor manufacturing hubs in China, Taiwan, South Korea, and Japan are driving growth in this region.

North America and Europe also represent significant markets, propelled by advanced research and development activities and a robust presence of major industry players, particularly in the U.S. These regions continue to be centers of innovation and technological advancements, contributing substantially to the global market's evolution.

Market Growth Factors

Several factors are expected to drive the growth of the thin film deposition equipment market over the coming years:

• Innovation in Deposition Techniques:

The development of new, low-temperature deposition methods is anticipated to reduce manufacturing costs and broaden the scope for new material applications.

• Expansion of Renewable Energy Installations:

The global shift towards renewable energy, especially solar energy, is set to drive significant investments in thin film deposition equipment.

• Rising Semiconductor Demand:

Increasing demand for semiconductors-integral to various industries including automotive, consumer electronics, and telecommunications-will further stimulate market growth.

• Technological Miniaturization:

The trend towards smaller, more efficient electronic devices necessitates precision deposition techniques, thereby fostering market expansion.

Future Outlook

Looking ahead, the thin film deposition equipment market is poised for sustained growth and transformation. Analysts predict that continuous innovation in deposition processes and an increasing focus on sustainability will be key drivers. Manufacturers are expected to invest heavily in research and development to create next-generation equipment that not only meets the evolving demands of high-tech industries but also adheres to environmental regulations. With a forecasted CAGR of 9.4%, the industry is set to see transformative shifts that will redefine manufacturing standards across semiconductor, solar cell, and flexible electronics applications.

Buy this Premium Research Report to explore detailed market trends - https://www.transparencymarketresearch.com/checkout.php?rep_id=84535<ype=S

Why Buy This Report?

Investors, industry stakeholders, and market participants will find this comprehensive report invaluable. It offers:

• In-Depth Analysis: Detailed insights into market trends, key drivers, and challenges.

• Strategic Insights: A thorough examination of competitive landscapes and recent developments.

• Regional & Segment Analysis: Clear breakdowns of market segmentation, regional dynamics, and growth opportunities.

• Future Forecasts: Reliable projections and forecasts, helping stakeholders make informed decisions.

• Actionable Intelligence: Critical data to support strategic planning, product development, and investment decisions in a rapidly evolving market.

Explore Latest Research Reports by Transparency Market Research

Automated Material Handling Market: https://www.transparencymarketresearch.com/automated-material-handling-market.html

Phototransistor Market: https://www.transparencymarketresearch.com/phototransistor-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Thin Film Deposition Equipment Market Poised for 9.4% CAGR Growth, Surpassing USD 70 Billion by 2031 here

News-ID: 3930427 • Views: …

More Releases from Transparency Market Research

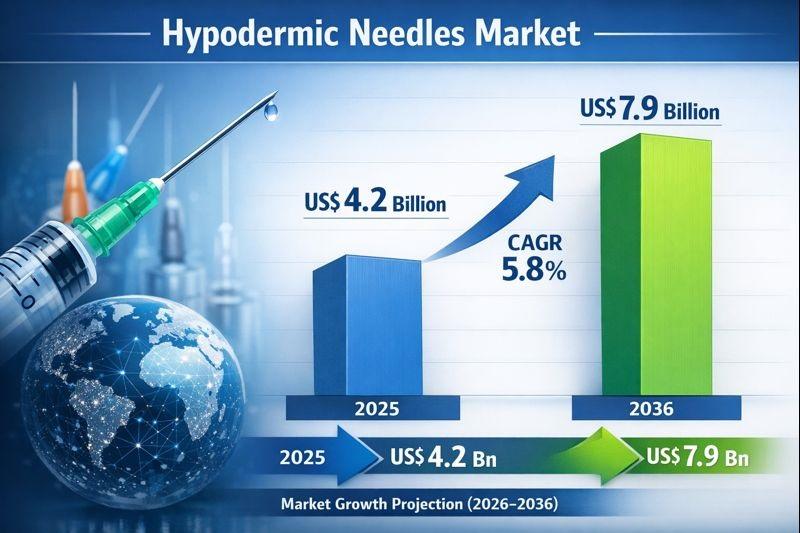

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

Connected Car Market to Reach US$ 467.2 Billion by 2036, Driven by Rising Adopti …

The global connected car market is entering a high-growth phase as vehicles increasingly evolve into software-defined, data-driven mobility platforms. Valued at US$ 100.8 billion in 2025, the market is projected to reach an impressive US$ 467.2 billion by 2036, expanding at a robust CAGR of 12.3% from 2026 to 2036. This growth is fueled by rapid advancements in automotive connectivity, rising consumer demand for intelligent features, and strong integration of…

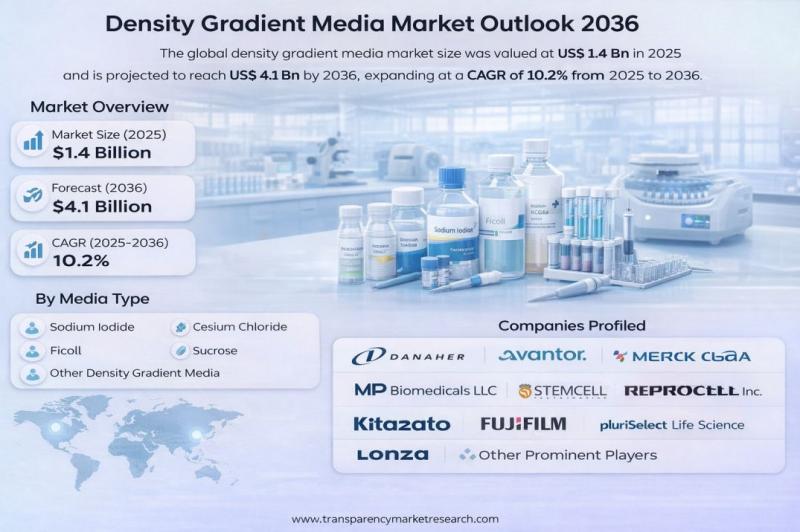

Density Gradient Media Market to Reach US$ 4.1 Billion by 2036, Driven by Rapid …

The global density gradient media market was valued at US$ 1.4 Billion in 2025 and is projected to reach US$ 4.1 Billion by 2036, expanding at a robust CAGR of 10.2% from 2025 to 2036. The market's rapid growth is primarily driven by increasing demand for rapid infectious disease screening, expanding cell therapy and immunology research, and continuous technological advancements improving sensitivity and multiplexing in laboratory workflows.

Access key findings and…

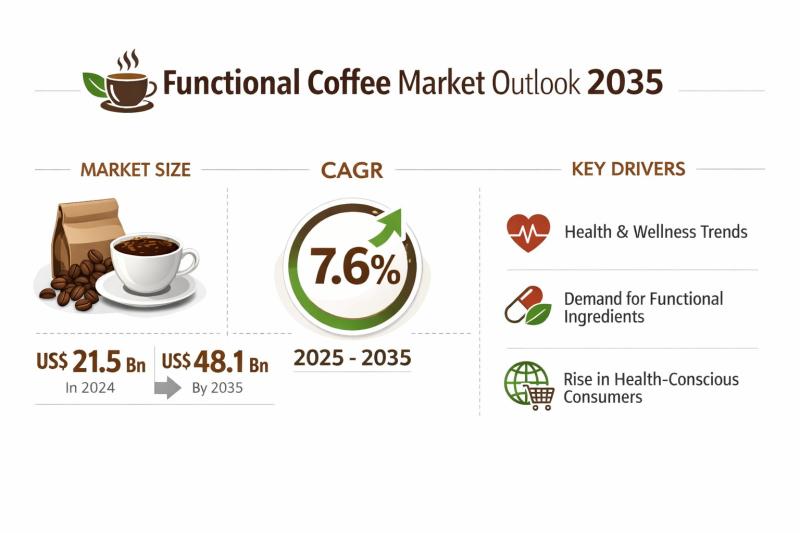

Functional Coffee Market Expanding at 7.6% CAGR Through 2035 - By Product Type / …

The global functional coffee market was valued at US$ 21.5 Bn in 2024 and is projected to reach US$ 48.1 Bn by 2035, expanding at a compound annual growth rate (CAGR) of 7.6% from 2025 to 2035. This steady growth trajectory reflects the strong convergence of coffee consumption habits with rising demand for functional and wellness-oriented beverages. Functional coffee has transitioned from a niche category to a mainstream product offering,…

More Releases for Deposition

Major Growth Driver Identified in 2025 Chemical Vapor Deposition Market: Rising …

Stay ahead with our updated market reports featuring the latest on tariffs, trade flows, and supply chain transformations.

Chemical Vapor Deposition Market Size Valuation Forecast: What Will the Market Be Worth by 2025?

The market size of chemical vapor deposition has experienced swift expansion in the past few years. Experts predict that it will surge from $38.84 billion in 2024 to a staggering $42.89 billion in 2025, with a compound annual growth…

Atomic Layer Deposition Market: Atomic Layer Deposition Market to Hit USD 6.06B …

Atomic Layer Deposition Market Scope:

Key Insights : Atomic Layer Deposition Market size was valued at USD 2.10 billion in 2022 and is poised to grow from USD 2.36 billion in 2023 to USD 6.06 billion by 2031, growing at a CAGR of 12.50% during the forecast period (2024-2031).

Discover Your Competitive Edge with a Free Sample Report :https://www.skyquestt.com/sample-request/atomic-layer-deposition-market

Access the full 2024 Market report for a comprehensive understanding @https://www.skyquestt.com/report/atomic-layer-deposition-market

In-Depth Exploration of…

Atomic Layer Deposition Market Report 2024 - Atomic Layer Deposition Market Size …

"The Business Research Company recently released a comprehensive report on the Global Atomic Layer Deposition Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The atomic layer deposition…

Optical Coating Market, By Technology (Vacuum Deposition Technology, Ion-Assiste …

Market Definition

An optical coating contains one or more thin layers of material deposited on an optical component such as a lens or mirror, which modifies how the optic transmits and reflects light. One type of optical coating is an anti-reflective coating that reduces unwanted reflections from surfaces, and generally used on camera lenses and spectacle. Another type is the high-reflector coating, which can produce mirrors that reflect the light greater than 99.99% of the light and fall on them. More complex…

Vapour Deposition Market Global Industry Analysis By Technology Are Chemical Vap …

Vapour deposition market is going to have a rocket boom for their sales, import, export and revenue in the forecast period of 2018-2025.

The report is generated based on the market type, size of the organization, availability on-premises and the end-users’ organization type, and the availability in areas such as North America, South America, Europe, Asia-Pacific and Middle East & Africa.

The base year for calculation in the report is taken as…

Physical Vapor Deposition Market Global Briefing 2017

Global Physical Vapor Deposition Market Research Report 2017 provides a unique tool for evaluating the market, highlighting opportunities, and supporting strategic and tactical decision-making. This report recognizes that in this rapidly-evolving and competitive environment, up-to-date marketing information is essential to monitor performance and make critical decisions for growth and profitability. It provides information on trends and developments, and focuses on markets and materials, capacities and technologies, and on the changing…