Press release

Catalyst Market Report 2025 Edition: Industry Market Size, Share, Growth, and Competitor Analysis

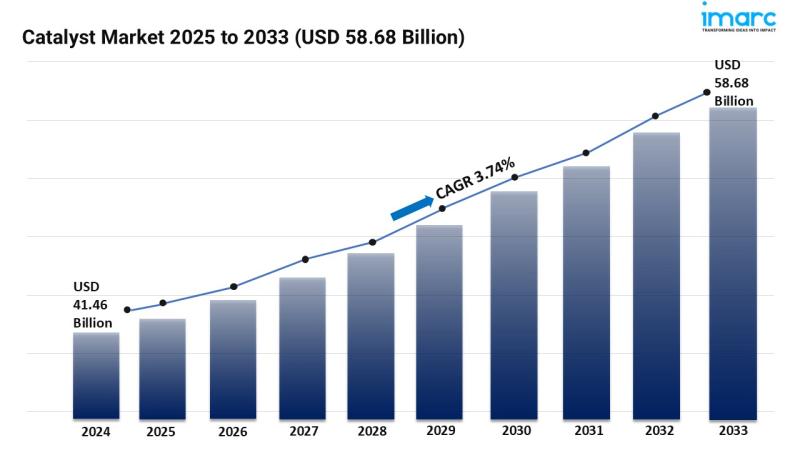

Market Overview:The catalyst market is experiencing rapid growth, driven by green catalyst innovation, specialty catalyst demand, and catalyst recycling & recovery. According to IMARC Group's latest research publication, "Catalyst Market Size, Share, Trends and Forecast by Type, Process, Raw Material, Application, and Region, 2025-2033", The global catalyst market size was valued at USD 41.46 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 58.68 Billion by 2033, exhibiting a CAGR of 3.74% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/catalyst-market/requestsample

Our report includes:

● Market Dynamics

● Market Trends And Market Outlook

● Competitive Analysis

● Industry Segmentation

● Strategic Recommendations

Factors Affecting the Growth of the Catalyst Industry:

● Green Catalyst Innovation:

The catalyst market is experiencing an intensive change to the green catalyst innovation, which is inspired by the immediate requirement for environmental rules and the immediate need for sustainable chemical processes. It is gaining fuel from the growing demand for dynamic catalysts that enable the use of renewable feed ox, reduces waste production and reduces energy consumption. Manufacturers are heavy investments in the development of catalysts that facilitate bio -based chemical production, carbon dioxide use and effective conversion of biomass. In addition, a focus can be focused on asymmetrical catalysts that can be easily extracted and recycled, and speed up by promoting a circular economy approach. The growth of catalysts with increased selectivity and activity reduces the need for hard response and reduces the formation of by -product. Integration of advanced properties Characteristic techniques and calculation modeling accelerate the discovery and adaptation of green catalysts. Increasing demand for catalysts that support the production of biodegradable polymers and durable fuels, and operate innovation in catalis research. Emphasis on life cycle assessment and environmental impact analysis are more environmentally developing benign catalytic processes. This green catalistic innovation is not just about using durable materials; It is about reducing environmental impact and redesigned chemical processes to promote more lasting chemical industry.

● Specialty Catalyst Demand:

The catalyst market is witnessing an increase in special catalyst needs, driven by the increasing complexity of chemical processes and the need for high -performance materials. This dynamic is met by the increasing demand for catalysts such as the production of fine chemicals, drugs and advanced materials. Manufacturers focus on developing catalysts with tailor -made properties, intended as high selectivity, activity and stability, to meet the specific requirements for applications. Furthermore, the integration of advanced synthesis techniques, such as nuclear layer provision and nanopartic technique, enable to create catalysts with precise, their structure and company. Development of catalysts that can function under mild reaction conditions, and expand the applications in sensitive chemical processes. Increase the demand for catalysts such as the production of high purity chemicals and special polymers drives innovation in catalysts design and synthesis. Catalysts focusing on stabilization and support materials enhance catalytic stability and recycling in specific applications. Integration of process -intensive technologies enables the development of more efficient and cost -effective catalytic processes. This particular catalyst requirement is not just about improvement in catalyst performance; It is about creating a catalyst solution that enables the production of high value products with increased efficiency and stability.

● Catalyst Recycling & Recovery:

The catalyst market is experiencing increasing emphasis on catalysis recovery and recovery, preservation of resources, the need to reduce waste and reduce environmental effects. This is fuel by increasing the lack of dynamic significant raw materials and increasing the cost of catalyst production. Manufacturers invest in developing technologies for effective extraction and lifting of catalysts used. In addition, the focus reduces on recycling processes with closed loops and maximizes resource use. The development of advanced separation and cleaning techniques enables the extraction of valuable metals and rare earth elements from the catalysts used. The increasing demand for sustainable and circular economics practice continues to use a catalysist -recycling initiative. Emphasis on regulator compliance and environmental management promotes the implementation of responsible catalytic management practices. Integration of data analysis and tracking systems is enabled to manage catalyst invention and effective control of recycling processes. The development of partnerships and collaboration between catalyst manufacturers, recycling companies and end users promotes the development of sustainable catalyst life cycle management strategies. This catalysis and recovery is not just about waste management; It is about creating a permanent and resource -educated catalyst's life cycle that reduces the environmental impact and promotes a circular economy.

Buy Full Report: https://www.imarcgroup.com/checkout?id=6370&method=1670

Leading Companies Operating in the Global Catalyst Industry:

● Albemarle Corporation

● Arkema S.A.

● Axens SA

● BASF SE

● Chevron Phillips Chemical Company LLC

● Clariant AG

● Dow Inc.

● Evonik Industries AG

● Exxon Mobil Corporation

● Honeywell International Inc.

● Johnson Matthey

● Shell plc

● W. R. Grace and Co. (Standard Industries Inc.)

● Zeolyst International Inc.

Catalyst Market Report Segmentation:

By Type:

● Heterogeneous Catalyst

● Homogeneous Catalyst

Heterogeneous catalyst represents the largest segment due to their ability to be easily separated from the reaction mixture and reused, enhancing process efficiency and cost-effectiveness.

By Process:

● Recycling

● Regeneration

● Rejuvenation

Recycling exhibits a clear dominance in the market because catalysts play a crucial role in enabling efficient and sustainable recovery and reuse of valuable materials, meeting increasing environmental regulations and resource conservation needs.

By Raw Material:

● Chemical Compounds

● Peroxides

● Acids

● Amines

● Others

● Metals

● Precious Metals

● Base Metals

● Zeolites

● Others

Chemical compounds (peroxides, acids, amines, and others) account for the majority of the market share as they are essential in manufacturing various types of catalysts used across multiple industrial processes, ensuring consistent performance and high reactivity.

By Application:

● Chemical Synthesis

● Chemical Catalysts

● Adsorbents

● Syngas Production

● Others

● Petroleum Refining

● Fluid Catalytic Cracking (FCC)

● Alkylation

● Hydrotreating

● Catalytic Reforming

● Purification

● Bed Grading

● Others

● Polymers and Petrochemicals

● Ziegler Natta

● Reaction Initiator

● Chromium

● Urethane

● Solid Phosphorous Acid Catalyst

● Others

● Environmental

● Light-duty Vehicles

● Motorcycles

● Heavy-duty Vehicles

● Others

Chemical synthesis (chemical catalysts, adsorbents, syngas production, and others) holds the biggest market share owing to the extensive use of catalysts in producing pharmaceuticals, polymers, and other fine chemicals, driving demand through continuous innovation and industrial growth.

Regional Insights:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

Asia Pacific's dominance in the catalyst market is attributed to rapid industrialization, significant investments in chemical and petrochemical industries, and a strong manufacturing base in various countries.

Ask Analyst for Sample Report: https://www.imarcgroup.com/request?type=report&id=6370&flag=C

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Catalyst Market Report 2025 Edition: Industry Market Size, Share, Growth, and Competitor Analysis here

News-ID: 3921287 • Views: …

More Releases from IMARC Group

Saudi Arabia Event Management Market Size to Hit USD 19,561.3 Million by 2033 at …

Saudi Arabia Event Management Market Overview

Market Size in 2024: USD 9,450.2 Million

Market Size in 2033: USD 19,561.3 Million

Market Growth Rate 2025-2033: 8.42%

According to IMARC Group's latest research publication, "Saudi Arabia Event Management Market Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the Saudi Arabia event management market was valued at USD 9,450.2 Million in 2024 and is projected to reach USD 19,561.3 Million by 2033, growing at a CAGR…

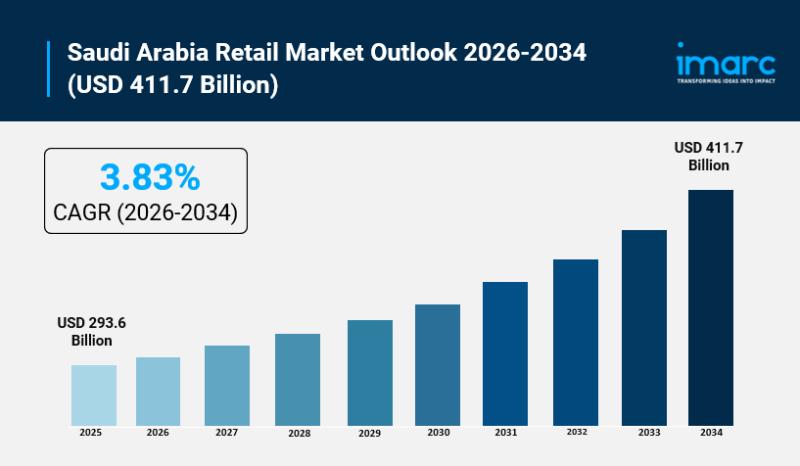

Saudi Arabia Retail Market Size to Surge to USD 411.7 Billion by 2034 | CAGR of …

Saudi Arabia Retail Market Overview

Market Size in 2025: USD 293.6 Billion

Market Size in 2034: USD 411.7 Billion

Market Growth Rate 2026-2034: 3.83%

According to IMARC Group's latest research publication, "Saudi Arabia Retail Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia retail market size was valued at USD 293.6 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 411.7 Billion by 2034, exhibiting a…

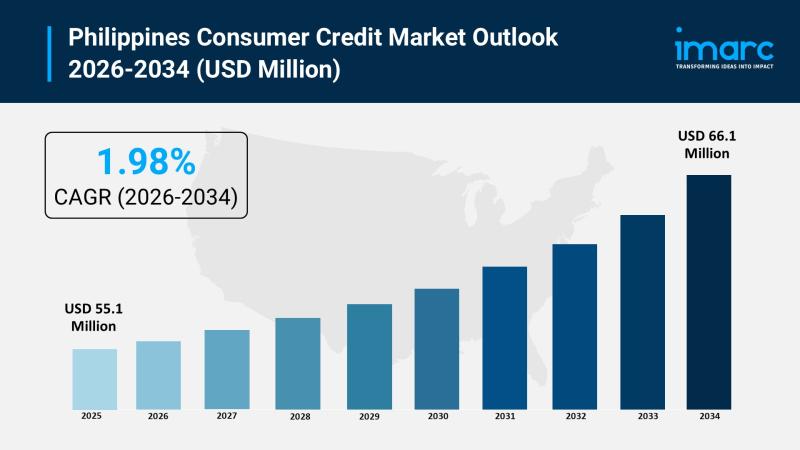

Philippines Consumer Credit Market 2026 | Worth USD 66.1 Million by 2034

Philippines Consumer Credit Market Overview:

The Philippines consumer credit market size reached USD 55.1 Million in 2025. The market is projected to reach USD 66.1 Million by 2034, exhibiting a growth rate (CAGR) of 1.98% during 2026-2034. The market is expanding steadily as rising financial inclusion, mobile-first lending platforms, and Buy Now Pay Later adoption bring formal credit to previously underserved Filipinos. Fintech innovation, neobank growth, and supportive BSP regulatory frameworks…

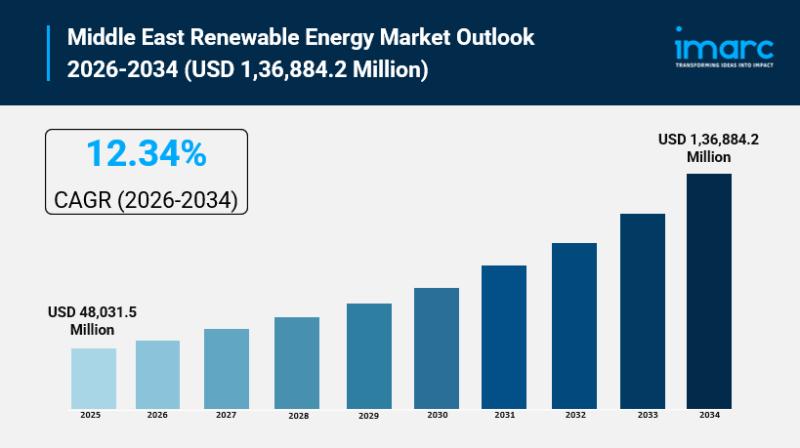

Middle East Renewable Energy Market Size to Hit USD 1,36,884.2 Million by 2034 | …

Middle East Renewable Energy Market Overview

Market Size in 2025: USD 48,031.5 Million

Market Size in 2034: USD 1,36,884.2 Million

Market Growth Rate 2026-2034: 12.34%

According to IMARC Group's latest research publication, "Middle East Renewable Energy Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Middle East renewable energy market size was valued at USD 48,031.5 Million in 2025. Looking forward, IMARC Group estimates the market to reach USD 1,36,884.2 Million by…

More Releases for Catalyst

Cr-based Alkanes Dehydrogenation Catalyst Market 2025: Innovations, Trends, and …

Los Angeles-United State: QY Research has recently published a research report titled, "Cr-based Alkanes Dehydrogenation Catalyst - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031" assessing various factors impacting its trajectory. The market research report is a perfect tool for digging deep into critical aspects of the global Cr-based Alkanes Dehydrogenation Catalyst market and closely understanding factors that influence its growth. Our research analysts are experienced enough…

Catalyst Market Economic Drivers Factors Influencing Catalyst Market Expansion - …

In recent years, the global Catalyst Market has witnessed a dynamic shift, influenced by changing consumer preferences, technological advancements, and a growing emphasis on sustainability. The Research report on Catalyst Market presents a complete judgment of the market through strategic insights on future trends, growth factors, supplier landscape, demand landscape, Y-o-Y growth rate, CAGR, pricing analysis. It also provides and a lot of business matrices including Porters Five Forces Analysis,…

Diesel Engine Catalyst Market Report 2024 - Diesel Catalyst Market Size And Grow …

"The Business Research Company recently released a comprehensive report on the Global Diesel Engine Catalyst Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive…

Continuous Catalyst Regeneration (CCR) Catalyst Market Segmentation & Analysis, …

Los Angeles, USA: QY Research has recently unveiled a comprehensive report titled, "Global Continuous Catalyst Regeneration (CCR) Catalyst Market Report: Insights, Forecast to 2030." This detailed analysis examines the multiple elements shaping the future of the global Continuous Catalyst Regeneration (CCR) Catalyst market.

The Continuous Catalyst Regeneration (CCR) Catalyst report serves as an invaluable resource for industry players, providing precise and extensive research insights necessary for strategic decision-making. The analysts have…

Refinery Catalyst Market: Refinery Catalyst Market Projections: Innovations and …

Market Overview:

Refinery catalysts are used in petroleum refining operations to facilitate and accelerate chemical reactions for conversion of crude oil into useful petroleum products like gasoline, diesel, jet fuel etc. Without catalysts, refining processes would be inefficient or not commercially viable.

Get Sample Report with Global Industry Analysis @ https://www.coherentmarketinsights.com/insight/request-sample/736

Major Players Are:

✤ BP Global and Royal Dutch Shell. Other key industry participants include YARA International

✤ Foster Wheeler AG

✤ OXEA GmbH

✤ W…

Global Homogeneous Catalyst Market, Global Homogeneous Catalyst Industry, Covid- …

Homogeneous catalysts such as transition metal complexes have been utilized for the chemical reactions on the biopolymers. Homogeneous catalysts were the catalysts of choice in the early days of metathesis reactions. They entailed of a transition metal compound and a non-transition metal compound, primarily organometallic as cocatalysts. Although, the homogeneous catalysts have high probable to speed up the reaction rate, augment selectivity, conversion rate, and diminish side reactions, they cannot…