Press release

Die Bonding Machine Market Poised to Reach USD 2.1 Billion by 2031 Amidst Advancements in Semiconductor Packaging - Persistence Market Research

The global die bonding machine market is witnessing significant growth, driven by rapid advancements in semiconductor packaging technologies. As industries continue to demand more efficient, high-performance electronic components, die bonding machines play a crucial role in assembling semiconductor devices with precision and reliability. According to Persistence Market Research, the market is anticipated to reach USD 2.1 billion by 2031, fueled by increasing adoption in consumer electronics, automotive, telecommunications, and industrial applications.Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/34316

Market Overview and Growth Drivers

The die bonding machine market has experienced steady expansion due to technological innovations and the rising need for compact, efficient electronic devices. Semiconductor manufacturers are continually improving their packaging techniques to enhance device performance, reduce power consumption, and extend the lifespan of electronic products. The growing penetration of 5G technology, AI, and IoT further amplifies the demand for advanced semiconductor packaging solutions, consequently boosting the need for high-precision die bonding machines.

One of the primary growth drivers is the miniaturization of electronic components. As devices become smaller, the precision and accuracy of die bonding machines become more critical. Modern semiconductor applications require sub-micron level accuracy, which has led to the adoption of advanced die bonding technologies such as flip-chip bonding, epoxy die attach, eutectic bonding, and hybrid bonding.

Additionally, the automotive sector is witnessing increased demand for electronic components, including advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) power modules. The integration of semiconductors in these applications necessitates robust die bonding solutions that can handle high-reliability packaging.

Key Market Segments

The die bonding machine market is segmented based on type, application, and region.

By Type:

Flip Chip Bonders - High demand in applications requiring high-density interconnects and superior electrical performance.

Eutectic Bonders - Preferred for high-power semiconductor applications due to their ability to create strong, thermally stable connections.

Epoxy Die Bonders - Widely used in consumer electronics and LED packaging for their cost-effectiveness and versatility.

Hybrid Bonders - Gaining traction in advanced packaging applications where a combination of bonding techniques is required.

By Application:

Consumer Electronics - Smartphones, tablets, wearables, and other smart devices.

Automotive Electronics - ADAS, powertrain control units, EV battery management systems.

Telecommunications - 5G network infrastructure, optical communication modules.

Industrial & Medical Devices - IoT sensors, implantable medical devices, and industrial automation components.

Regional Analysis

The Asia-Pacific region dominates the die bonding machine market, with China, Taiwan, South Korea, and Japan being major contributors. This dominance is attributed to the presence of leading semiconductor manufacturers and packaging service providers. Additionally, government initiatives supporting domestic semiconductor production in countries like India and Vietnam are expected to boost regional market growth.

North America and Europe are also key markets, driven by strong R&D activities, the presence of leading technology firms, and increased adoption of advanced driver-assistance systems (ADAS) and high-performance computing (HPC) solutions. The U.S. semiconductor industry is witnessing substantial investment, further propelling demand for state-of-the-art die bonding machines.

Technological Advancements Shaping the Market

The evolution of automation and AI-driven die bonding solutions has significantly improved production efficiency, reducing human errors and operational costs. Modern die bonding machines incorporate machine learning algorithms, real-time monitoring, and adaptive control systems, allowing semiconductor manufacturers to achieve higher throughput and better yield rates.

The shift toward hybrid and heterogeneous integration has also led to the development of advanced die bonding techniques that accommodate multiple chip architectures on a single substrate. As demand for high-bandwidth memory (HBM), advanced system-in-package (SiP), and chiplet technology grows, die bonding machines must continuously evolve to support these cutting-edge applications.

Market Challenges and Restraints

Despite the promising growth trajectory, the die bonding machine market faces several challenges. High capital investment costs associated with advanced die bonding equipment pose a significant barrier for small and medium-sized enterprises (SMEs). Additionally, supply chain disruptions, raw material shortages, and trade restrictions can impact semiconductor manufacturing activities, affecting the demand for die bonding machines.

Furthermore, the semiconductor industry is facing a skilled labor shortage, as the complexity of packaging technologies requires highly trained personnel. Manufacturers are addressing this challenge by investing in automation and AI-based process optimization to reduce dependency on manual labor.

Future Outlook and Emerging Opportunities

The future of the die bonding machine market looks promising, with numerous growth opportunities emerging from key industries. The ongoing expansion of 5G networks, AI-driven applications, automotive electrification, and data center advancements will continue to drive demand for semiconductor packaging solutions, ensuring steady market growth.

Innovations in advanced packaging techniques, such as wafer-level packaging (WLP), through-silicon vias (TSVs), and micro-transfer printing, will further push the boundaries of die bonding technology. Companies investing in automated die bonding solutions, AI-powered defect detection, and real-time production analytics will gain a competitive edge in the evolving semiconductor landscape.

Conclusion

The die bonding machine market is set to experience robust growth, reaching USD 2.1 billion by 2031, driven by technological advancements and increasing semiconductor adoption across diverse industries. As miniaturization, high-performance computing, and AI integration continue to shape the future of electronics, die bonding machines will remain a critical enabler in semiconductor packaging. Market players focusing on innovation, automation, and strategic collaborations will be well-positioned to capitalize on the growing demand for high-precision die bonding solutions.

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Die Bonding Machine Market Poised to Reach USD 2.1 Billion by 2031 Amidst Advancements in Semiconductor Packaging - Persistence Market Research here

News-ID: 3916438 • Views: …

More Releases from Persistence Market Research

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

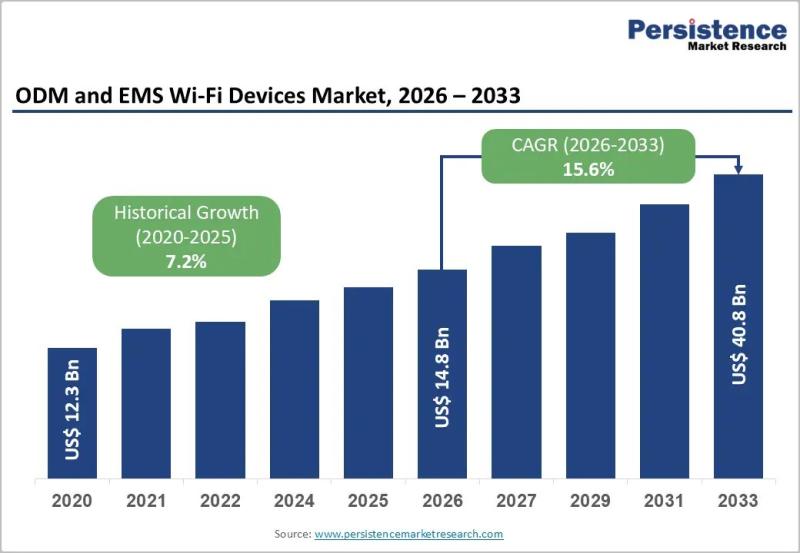

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

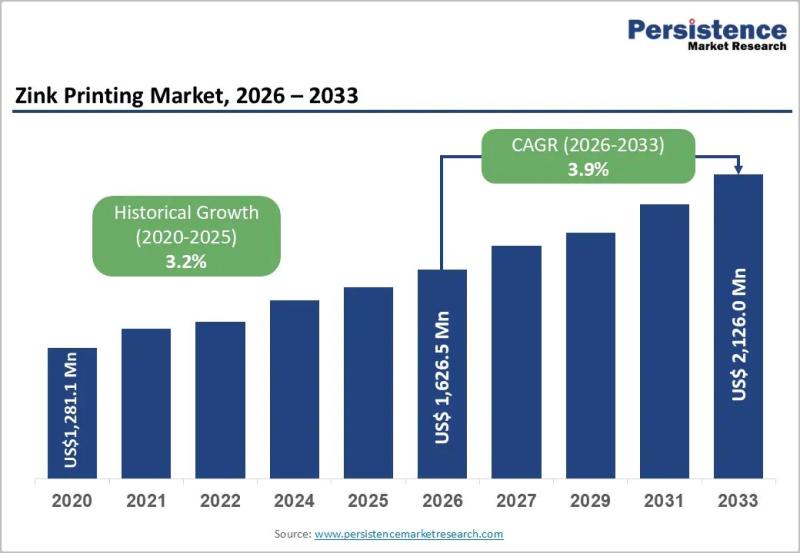

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

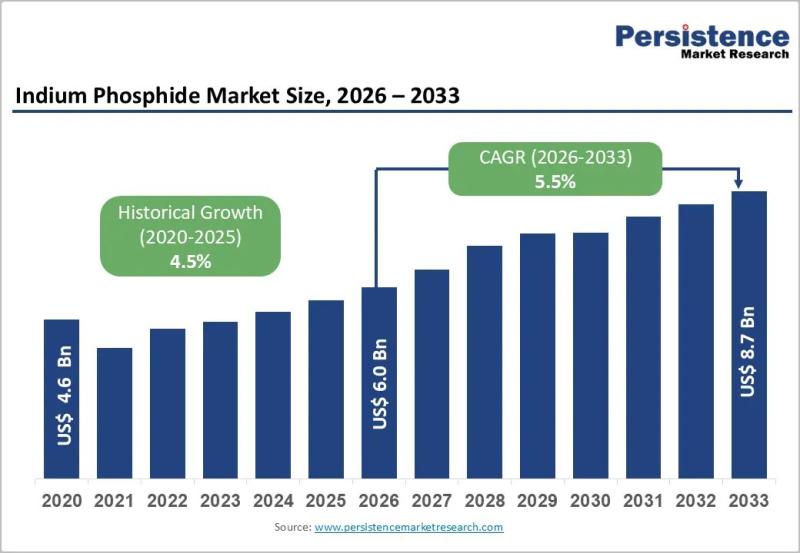

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

More Releases for USD

Bone Cement Market Outlook USD 1,871.10M-USD 3,512.31M

How Is the Bone Cement Market Supporting the Rise of Modern Orthopedic Surgery?

The Bone Cement Market plays a critical role in modern orthopedic and spinal procedures, acting as a foundational material for joint replacement, fracture fixation, and vertebral stabilization. Bone cement is widely used to anchor implants, restore bone structure, and improve patient mobility-making it an essential component of musculoskeletal care.

In 2025, the global bone cement market was valued at…

Autologous Cell Therapy Market Outlook USD 9.31B-USD 54.83B

How Is the Autologous Cell Therapy Market Redefining the Future of Precision Medicine?

The Autologous Cell Therapy Market is rapidly emerging as one of the most transformative areas in modern healthcare, offering highly personalized treatment options for complex and chronic diseases. By using a patient's own cells to repair, replace, or regenerate damaged tissues, autologous cell therapy minimizes immune rejection risks while maximizing therapeutic effectiveness.

In 2025, the global autologous cell therapy…

PACS Market USD 5.59B in 2025, USD 9.73B by 2035

Picture Archiving and Communication System (PACS) Market Expands as Digital Imaging Transforms Global Healthcare

Introduction: PACS at the Core of Modern Medical Imaging

The healthcare industry is undergoing a rapid digital transformation, with medical imaging playing a critical role in diagnosis, treatment planning, and patient monitoring. At the heart of this transformation lies the Picture Archiving and Communication System (PACS)-a technology that enables the storage, retrieval, management, and sharing of medical images…

Global HEOR Market USD 1.70B-USD 6.03B

Health Economics and Outcomes Research (HEOR) Market Accelerates as Value-Based Healthcare Redefines Global Decision-Making

Introduction: The Growing Importance of HEOR in Modern Healthcare

The global healthcare industry is undergoing a profound transformation, shifting from volume-driven care models to value-based healthcare systems that prioritize patient outcomes, cost efficiency, and real-world effectiveness. At the center of this transformation lies Health Economics and Outcomes Research (HEOR)-a discipline that evaluates the economic value, clinical outcomes, and…

Foam Tape Market Outlook 2035: Industry Growth from USD USD 4.89 Billion (2025) …

The Foam Tape Market plays a vital role in modern industrial and manufacturing ecosystems. Foam tapes are pressure-sensitive adhesive products manufactured using materials such as polyurethane, polyethylene, PVC, and acrylic foam. These tapes are widely used for bonding, sealing, insulation, cushioning, vibration damping, and noise reduction across multiple industries. Their ability to replace traditional mechanical fasteners like screws, bolts, and rivets has positioned foam tapes as a preferred solution in…

Chlorella Market Reach USD 465.85 Million USD by 2030

Market Growth Fueled by Increased Adoption of Plant-Based Proteins and Health Supplements

Global Chlorella Market size was valued at USD 303.75 Mn. in 2023 and the total Chlorella revenue is expected to grow by 6.3 % from 2024 to 2030, reaching nearly USD 465.85 Mn. . The growth of the market is majorly due to increase in the consumer awareness about health, the inclination towards plant-based food such as chlorella and…