Press release

How To Setup a Transformer Oil Manufacturing Plant

Setting up a transformer oil manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Transformer Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a transformer oil manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Transformer oil is a highly refined insulating oil used in electrical transformers, circuit breakers, and other high-voltage equipment to provide insulation and cooling. It is primarily derived from mineral oil or synthetic compounds and is designed to withstand high temperatures while maintaining dielectric strength. Transformer oil is playing a crucial role in preventing electrical discharges, reducing overheating, and ensuring the efficient operation of power distribution systems. Additionally, it is protecting transformer components from oxidation and moisture, extending their lifespan and performance. Transformer oil exhibits excellent thermal stability and oxidation resistance, preventing sludge formation and maintaining efficient insulation over time. It is available in different types, including mineral-based, silicone, and bio-based oils, catering to various operational and environmental requirements.

The market is experiencing significant growth as the demand for reliable power transmission and distribution systems is continuously increasing. The rapid expansion of electricity networks, particularly in emerging economies, is driving the need for efficient transformer insulation and cooling solutions. In addition to this, governments and energy authorities are increasingly investing in grid modernization projects, further boosting transformer oil consumption. The growing installation of high-voltage transformers in industrial and commercial sectors is also contributing to market expansion. Moreover, advancements in renewable energy infrastructure are prompting utilities to integrate more transformers, increasing the demand for high-performance insulating oils. The rising adoption of smart grids is further supporting the use of advanced transformer oil formulations to enhance efficiency and longevity.

Request for a Sample Report: https://www.imarcgroup.com/transformer-oil-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up a Transformer Oil Plant.

1. Market Analysis

The report provides insights into the landscape of the transformer oil industry at the global level. The report also provides a segment-wise and region-wise breakup of the global transformer oil industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of transformer oil, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the transformer oil manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=15603&flag=C

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for transformer oil manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for transformer oil production.

• Estimated costs and suppliers.

Raw Material Costs

• Types of materials required and sourcing strategies.

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a transformer oil manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand.

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How To Setup a Transformer Oil Manufacturing Plant here

News-ID: 3911466 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

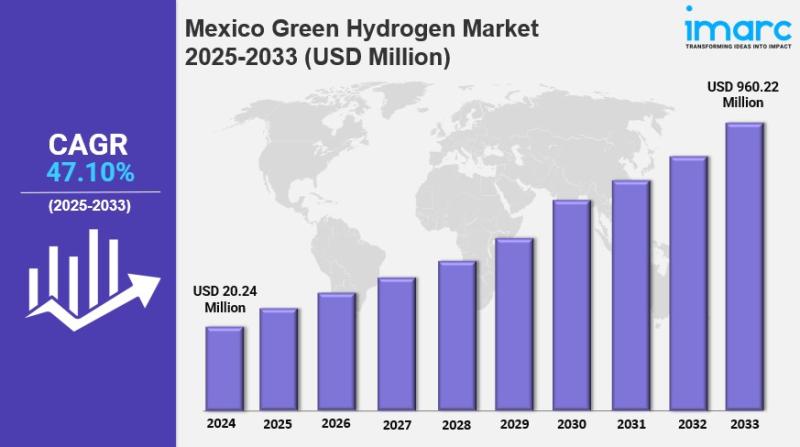

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Transformer

Mobile Transformer Market

Mobile Transformer Market size is estimated to be USD 5.45 Billion in 2024 and is expected to reach USD 9.78 Billion by 2033 at a CAGR of 6.9% from 2026 to 2033.

What are the potential factors contributing to the growth of the mobile transformer market?

The mobile transformer market is experiencing significant growth due to several key factors. Firstly, the increasing demand for reliable and efficient power supply in remote and…

Transformer Oil Market, Transformer Oil Market Size, Transformer Oil Market Shar …

The Transformer Oil Market research report consists of a detailed study of the market and the market dynamics that are related to the same. The in-depth data on the development of the market is presented in the Research report. Not only this but also the detailed data on the performance of the market for the forecast period are presented in the Transformer Oil Market research report. The performance analysis is…

Signal Transformer Market Estimated to a Hike in Growth By Signal Type: Audio Tr …

Acumen Research and Consulting has announced the addition of the "Signal Transformer Market” report to their offering.

The Signal Transformer Market Report 2018 is an in depth study analyzing the current state of the Signal Transformer Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Signal Transformer Market provides analysis of China market covering the industry trends, recent…

Southeast Asia Transformer market :Global Demand Analysis & Opportunity Outlook …

Abstract:

The Southeast Asia Transformer market size is $XX million USD in 2018 with XX CAGR from 2014 to 2018, and it is expected to reach $XX million USD by the end of 2024 with a CAGR of XX% from 2019 to 2024.

Request For Free Sample@ https://www.kennethresearch.com/sample-request-10071643

This report is an essential reference for who looks for detailed information on Southeast Asia Transformer market. The report covers data on Southeast Asia…

Global Transformer Cores Market Forecast 2018-2025 Sanbian Sci-Tech, Wujiang Tra …

Market study on Global Transformer Cores 2018 Research Report presents a professional and complete analysis of Global Transformer Cores Market on the current market situation.

Report provides a general overview of the Transformer Cores industry 2018 including definitions, classifications, Transformer Cores market analysis, a wide range of applications and Transformer Cores industry chain structure. The 2018's report on Transformer Cores industry offers the global Transformer Cores development history, development trends…

Transformer Oil Market by Type (Mineral Oil-Based, Silicone Oil-Based, Bio-based …

Transformer oil market sales to reach $3.4 billion by 2020, with the mineral oil-based transformer oil segment to maintain its dominance until 2020. In 2014, the consumption of transformer oils was 1,437.8 million litres across the globe, which is expected to increase at 6.3% from 2015 to 2020.

Transformer oils are electrical insulating oils stable at high temperature, which serves two important functions in a transformer, viz., suppression of arcing and…