Press release

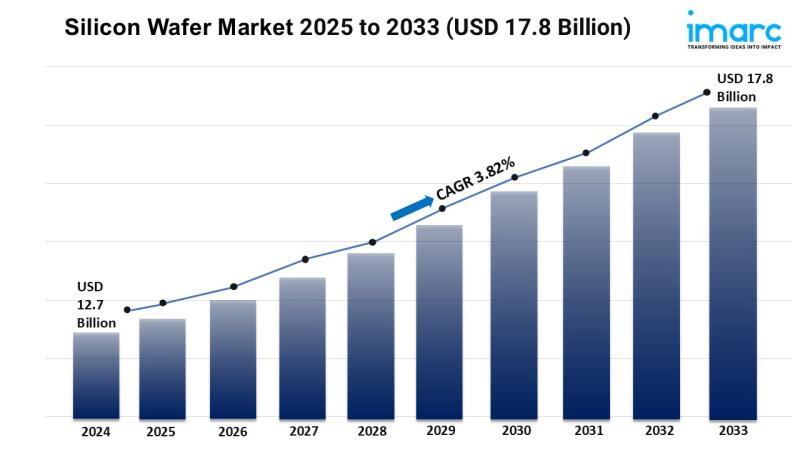

Silicon Wafer Market Size to Hit USD 17.8 Billion in 2033 | Exhibiting CAGR of 3.82%

Market Overview:The silicon wafer market is experiencing rapid growth, driven by growing demand for advanced nodes, rising adoption of 300mm wafers, and supply chain disruptions & geopolitical impact. According to IMARC Group's latest research publication, "Silicon Wafer Market Report by Wafer Size (0 - 100 mm, 100 - 200 mm, 200 - 300 mm, More than 300 mm), Type (N-type, P-type), Application (Solar Cells, Integrated Circuits, Photoelectric Cells, and Others), End Use (Consumer Electronics, Automotive, Industrial, Telecommunications, and Others), and Region 2025-2033", The global silicon wafer market size reached USD 12.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 17.8 Billion by 2033, exhibiting a growth rate (CAGR) of 3.82% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/silicon-wafer-market/requestsample

Our report includes:

● Market Dynamics

● Market Trends And Market Outlook

● Competitive Analysis

● Industry Segmentation

● Strategic Recommendations

Factors Affecting the Growth of the Silicon Wafer Industry:

● Growing Demand for Advanced Nodes:

As the semiconductor industry keeps moving towards smaller and more powerful chips, advanced-node silicon wafer markets are gaining traction. With technology nodes shrinking to 5nm, 3nm, and 2nm, manufacturers will need ultra-pure and high-quality wafers in order to increase density of transistors. Burst demand resulted from applications in AI, 5G, and high-performance computing. These companies invest in ultra-modern wafer fabrication techniques to fulfill the stringent requirements of next-generation chip design, and these investments are further accelerating the market growth.

● Rising Adoption of 300mm Wafers:

Wafers are gradually shifting from 200mm to 300mm since 300mm is cheaper and has a higher yield per wafer. Bigger wafers mean that a semiconductor manufacturer can produce more chips from a single good batch of silicon due to a lower production cost and better operational efficiency. Such a trend is being observed quite intensively in logic chips, memory, and power semiconductor manufacturing. As demand for consumer electronics, automotive chips, and IoT devices rises, leading foundries and wafer suppliers are ramping up 300mm production capacity to remain in the race.

● Supply Chain Disruptions & Geopolitical Impact:

With the demand for silicon wafers affected by supply chain disruption and geopolitical tensions, the industry is very concentrated in wafer production with a few major players, resulting in vulnerability to raw material shortages and trade barriers. Moreover, global supply chains are affected by ongoing geopolitical conflicts and government policies that force chipmakers to diversify their resources and invest in local manufacturing. Therefore, this alternate inclination is expected to foster fresh opportunities among local wafer manufacturers while changing the global semiconductor Production strategy.

Buy Full Report: https://www.imarcgroup.com/checkout?id=3095&method=1670

Leading Companies Operating in the Global Silicon Wafer Industry:

● GlobalWafers Singapore Pte. Ltd.

● Okmetic Oy

● Shanghai Simgui Technology Co. Ltd.

● Shin-Etsu Chemical Co., Ltd.

● Silicon Materials, Inc.

● Siltronic AG

● SK Siltron Co., Ltd.

● Sumco Corporation

● Tokuyama Corporation

● Virginia Semiconductor, Inc.

● Wafer Works Corporation

Silicon Wafer Market Report Segmentation:

Breakup by Wafer Size:

● 0 - 100 mm

● 100 - 200 mm

● 200 - 300 mm

● More than 300 mm

According to the silicon wafer market statistics, the growing need for chip production capacity and improved economies of scale is propelling the segment's growth

Breakup by Type:

● N-type

● P-type

P-type silicon wafers serve as the substrate for manufacturing integrated circuits (ICs).

Breakup by Application:

● Solar Cells

● Integrated Circuits

● Photoelectric Cells

● Others

Silicon wafers provide the base material for solar cell fabrication. These wafers are typically made from high-purity silicon ingots that are sliced into thin and circular discs using diamond wire saws or other cutting methods.

Breakup by End Use:

● Consumer Electronics

● Automotive

● Industrial

● Telecommunications

● Others

The increasing utilization of various mobile devices, such as smartphones, tablets, laptops, etc., to access the internet and connect with other people is elevating the silicon wafer market revenue in this segmentation.

Ask Analyst for Sample Report: https://www.imarcgroup.com/request?type=report&id=3095&flag=C

Regional Insights:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

the Asia-Pacific region has been witnessing rapid industrialization and urbanization. This has led to an increased demand for electronic devices, semiconductors, and photovoltaic products. Moreover, the rising number of semiconductor manufacturing facilities and suppliers is also acting as another significant growth-inducing factor.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Silicon Wafer Market Size to Hit USD 17.8 Billion in 2033 | Exhibiting CAGR of 3.82% here

News-ID: 3911289 • Views: …

More Releases from IMARC Group

UK Biotechnology Market Size to Reach USD 41.47 Billion by 2033, Growing at 7.22 …

UK Biotechnology Market Summary:

• The UK Biotechnology Market size reached USD 22.00 Billion in 2024.

• Market is projected to reach USD 41.47 Billion by 2033.

• London, South East, North West, East of England, South West, Scotland, West Midlands, Yorkshire and The Humber, East Midlands, and Others dominate with a significant market share.

• Growth driven by rising biopharmaceutical R&D investments, strong government support for life sciences, and increasing adoption of advanced genomics and personalized medicine.

IMARC…

Brazil Energy Storage Market Size to Reach USD 4,478.12 Million by 2034, Growing …

Brazil Energy Storage Market Summary:

• The Brazil Energy Storage Market size reached USD 216.97 Million in 2025.

• Market is projected to reach USD 4,478.12 Million by 2034.

• Southeast Brazil dominates with a significant market share.

• Growth driven by rising renewable energy integration, grid modernization initiatives, and increasing investments in battery technologies.

IMARC Group, a leading market research company, has released its latest report titled Brazil Energy Storage Market. The study provides a detailed analysis of…

India Diagnostic Labs Market Outlook 2026-2034: AI Integration, Growth Drivers & …

According to the latest research report titled "India Diagnostic Labs Market Size, Share, Trends and Forecast by Provider Type, Test Type, Sector, End User, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

How Big is the India Diagnostic Labs Market?

The India diagnostic labs market size was valued at USD 10.95 Billion in 2025 and is projected to reach USD…

France Cement Market Size to Reach USD 20,912.99 Million by 2034, Growing at 4.9 …

France Cement Market Summary:

• The France Cement Market size reached USD 13,501.05 Million in 2025.

• Market is projected to reach USD 20,912.99 Million by 2034.

• Northern and Île-de-France regions dominate with a significant market share.

• Growth driven by expanding infrastructure modernization projects, rising residential construction activities, and increasing adoption of sustainable and low-carbon cement solutions.

IMARC Group, a leading market research company, has released its latest report titled "France Cement Market." The study provides a…

More Releases for Wafer

Semiconductor Silicon Wafer Market Is Going to Boom |• Silicon Wafer • Globa …

Worldwide Market Reports has released a new in-depth research study on the "Semiconductor Silicon Wafer Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities, technological advancements, innovation…

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market Size, Trends & F …

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market Size

The global Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market is projected to grow from US$ 1227 million in 2024 to US$ 1672.7 million by 2030, at a Compound Annual Growth Rate (CAGR) of 5.3% during the forecast period.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-38F13137/Global_Semiconductor_Wafer_Electrostatic_Chucks_for_300mm_Wafer_Market_Research_Report_2023?utm_source=openpr&utm_medium=referral

The US & Canada market for Semiconductor Wafer Electrostatic Chucks for 300mm Wafer is estimated to increase from $ million in…

Wafer Hybrid Bonding Equipment Market Share Driven by Wafer-to-Wafer Technology …

Wafer Hybrid Bonding Equipment Market Size

The global market for Wafer Hybrid Bonding Equipment was valued at US$ 164 million in the year 2024 and is projected to reach a revised size of US$ 756 million by 2031, growing at a CAGR of 24.7% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-31W14822/Global_Wafer_Hybrid_Bonding_Equipment_Market_Insights_Forecast_to_2029

The Wafer Hybrid Bonding Equipment market is experiencing accelerated growth, driven by increasing demand for advanced semiconductor packaging technologies that enable higher…

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market

The global Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market was valued at US$ 1165 million in 2023 and is anticipated to reach US$ 1672.7 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030.

View Sample Report

https://reports.valuates.com/request/sample/QYRE-Auto-38F13137/Global_Semiconductor_Wafer_Electrostatic_Chucks_for_300mm_Wafer_Market_Research_Report_2023

Report Scope

The Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market size, estimations, and forecasts are provided in terms of output/shipments (Units) and revenue…

Automatic Mounter Wafer Equipment Market Report 2018: Segmentation by Type (100 …

Global Automatic Mounter Wafer Equipment market research report provides company profile for Lintec Corporation, Nitto Denko, Tokyo Electron, Technovision, Takatori, Ultron Systems, DISCO Corp., Syagrus Systems, Advanced Dicing Technologies, Longhill Industries and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…

EMEA Solar Wafer Cutting Fluid PEG Market For Semiconductor, Solar Wafer, Crysta …

Latest industry research report on: EMEA (Europe, Middle East and Africa) Solar Wafer Cutting Fluid PEG Market : Industry Size, Share, Research, Reviews, Analysis, Strategies, Demand, Growth, Segmentation, Parameters, Forecasts

Request For Sample Report @ https://www.marketresearchreports.biz/sample/sample/1194694

Geographically, this report split EMEA into Europe, the Middle East and Africa, With sales (K MT), revenue (Million USD), market share and growth rate of Solar Wafer Cutting Fluid PEG for these regions, from 2012 to…