Press release

3D Printing Metal Market on Pace to Reach US$ 2.95 Bn by 2032 - Persistence Market Research

IntroductionThe 3D printing metal market has witnessed remarkable growth in recent years, driven by technological advancements and the increasing adoption of additive manufacturing across various industries. 3D printing metals provide numerous benefits, including reduced material wastage, enhanced design flexibility, and improved manufacturing efficiency. Industries such as aerospace, automotive, healthcare, and defense are leveraging 3D printing technologies to produce complex metal parts with high precision.

This report provides an in-depth analysis of the 3D printing metal market, highlighting key growth drivers, challenges, emerging trends, and regional dynamics. As the industry continues to evolve, metal-based additive manufacturing is expected to play a crucial role in transforming traditional production methods.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): www.persistencemarketresearch.com/samples/33210

Market Projections and Forecast

According to Persistence Market Research's projections, the global 3D printing metal market was valued at US$ 422.9 million in 2022 and is projected to reach US$ 2.95 billion by 2032, expanding at an astonishing compound annual growth rate (CAGR) of 21.4% over the forecast period.

This rapid growth is primarily driven by increasing investments in advanced manufacturing technologies, the rising demand for customized and lightweight metal components, and the expanding applications of 3D-printed metals across industrial sectors. North America and Europe are expected to lead the market, while the Asia-Pacific region is anticipated to witness the fastest growth.

Market Dynamics

Drivers of Market Growth

Advancements in Additive Manufacturing Technologies:

Continuous innovations in 3D printing processes, such as selective laser melting (SLM), electron beam melting (EBM), and direct metal laser sintering (DMLS), have enhanced the precision, efficiency, and scalability of metal additive manufacturing. These advancements enable manufacturers to produce complex geometries with superior mechanical properties.

Growing Demand in Aerospace and Automotive Industries:

The aerospace and automotive industries are among the largest adopters of 3D printing metals. The ability to produce lightweight, high-strength components using metals such as titanium, aluminum, and stainless steel is driving adoption in aircraft, spacecraft, and high-performance vehicles.

Expansion of Medical and Healthcare Applications:

The medical sector is increasingly utilizing 3D printing metals for producing patient-specific implants, prosthetics, and surgical instruments. The customization and biocompatibility offered by 3D printing technologies are driving adoption in orthopedic and dental applications.

Sustainability and Material Efficiency:

Unlike traditional subtractive manufacturing processes, 3D printing minimizes material wastage by utilizing only the required amount of metal powder. This sustainability aspect is appealing to industries seeking to reduce their environmental footprint.

Challenges in the Market

High Initial Investment and Production Costs:

The cost of 3D printing metals, including metal powders and high-performance printers, remains a major barrier to widespread adoption. Additionally, post-processing requirements such as heat treatment and surface finishing add to production costs.

Limited Material Availability:

While several metals are available for 3D printing, the selection remains limited compared to traditional manufacturing methods. The development of new metal alloys tailored for additive manufacturing is essential for broader adoption.

Quality Control and Certification Challenges:

Ensuring consistency, reliability, and regulatory compliance in 3D-printed metal components remains a challenge. Industries such as aerospace and medical require rigorous testing and certification before adoption.

Market Trends and Technological Innovations

Advancements in Metal Powder Materials:

Researchers and manufacturers are developing new metal powders, including high-performance alloys, refractory metals, and composite materials, to enhance the mechanical properties and performance of 3D-printed components.

Hybrid Manufacturing Approaches:

The integration of 3D printing with traditional manufacturing methods, such as CNC machining, is gaining traction. Hybrid approaches enable manufacturers to leverage the advantages of both technologies for superior results.

Expansion of Large-Scale 3D Printing:

New developments in large-format 3D printing systems are enabling the production of bigger and more complex metal structures, catering to applications in construction, defense, and heavy industries.

Automation and AI-Driven Design Optimization:

The use of artificial intelligence (AI) and machine learning in optimizing 3D printing designs, material usage, and printing parameters is becoming more prevalent, leading to enhanced efficiency and cost reduction.

3D Printing Metal Industry Segmentation

By Material Type:

Titanium

Aluminum

Stainless Steel

Nickel Alloys

Other Metal Powders

By Technology:

Selective Laser Melting (SLM)

Electron Beam Melting (EBM)

Direct Metal Laser Sintering (DMLS)

Binder Jetting

Other Technologies

By End-Use Industry:

Aerospace & Defense

Automotive

Healthcare

Industrial Manufacturing

Others

By Form:

Powder

Filament

Regional Analysis

North America

North America is expected to dominate the 3D printing metal market due to strong adoption in aerospace, defense, and healthcare industries. The presence of leading additive manufacturing companies and research institutions is further driving regional growth. The U.S. remains a major hub for innovation in 3D metal printing technologies.

Europe

Europe follows closely behind, with significant demand from automotive and industrial manufacturing sectors. Countries such as Germany, the UK, and France are investing heavily in additive manufacturing research and development, contributing to market expansion.

Asia-Pacific

The Asia-Pacific region is projected to witness the highest growth rate due to increasing industrialization, government initiatives supporting additive manufacturing, and the expanding aerospace and automotive industries in China, Japan, and India. The region's focus on technological advancements is fostering rapid market growth.

Key Companies Profiled in the Report

3D Systems Corporation

EOS GmbH

Stratasys Ltd.

Renishaw plc

GE Additive

Materialise NV

SLM Solutions Group AG

Desktop Metal, Inc.

HP Inc.

Velo3D, Inc.

Markforged, Inc.

ExOne Company

Future Outlook

The 3D printing metal market is poised for significant growth, driven by technological innovations, expanding applications, and increasing adoption across industries. The development of cost-effective metal powders, improved post-processing techniques, and AI-driven design optimization will further enhance market potential.

As industries continue to embrace additive manufacturing for its efficiency and sustainability benefits, the 3D printing metal market is expected to play a transformative role in modern manufacturing. Companies investing in research and innovation will gain a competitive edge, positioning themselves at the forefront of this rapidly evolving industry.

Conclusion

The global 3D printing metal market is set for exponential growth over the next decade, fueled by advancements in additive manufacturing, increased adoption in key industries, and a strong emphasis on sustainability. While challenges such as high costs and quality control remain, ongoing research and innovation are expected to overcome these barriers. As 3D printing technologies continue to evolve, the market is poised to redefine the future of metal manufacturing, enabling industries to achieve greater efficiency, customization, and performance.

Explore the Latest Trending "Exclusive Article" @

• https://apnewswire.hashnode.dev/glass-fiber-reinforced-plastic-composite-materials-market-outlook-and-future-projections

• https://vocal.media/stories/sustainable-growth-of-the-glass-fiber-reinforced-plastic-composites-industry-in-2025

• https://apnewswire.quora.com/Exploring-the-market-Potential-of-Glass-Fiber-Reinforced-Plastic-Composite-Materials-1

• https://apnewsmedia.stck.me/post/816066/Whats-Fueling-the-Rapid-Expansion-of-the-Glass-Fiber-Reinforced-Plastic-Composites-Market

• https://issuu.com/fmrresearch/docs/the_future_of_glass_fiber_reinforced_plastic_compo

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 3D Printing Metal Market on Pace to Reach US$ 2.95 Bn by 2032 - Persistence Market Research here

News-ID: 3899583 • Views: …

More Releases from Persistence Market Research

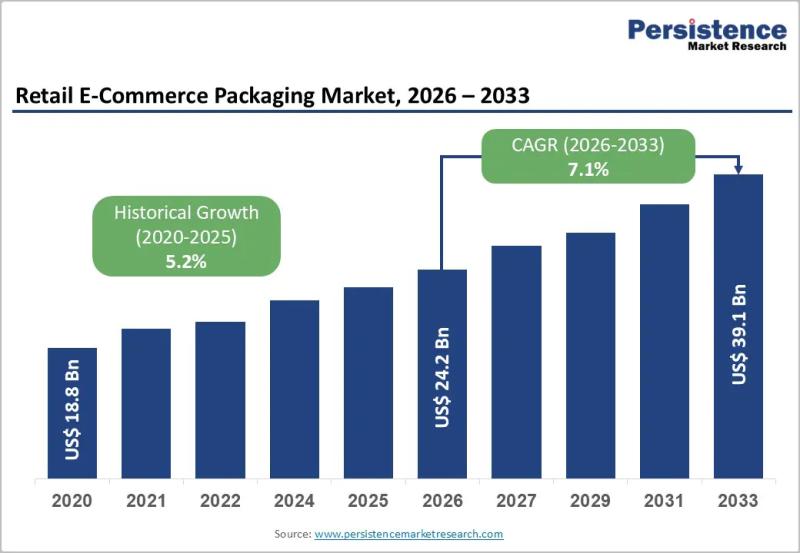

Retail E-Commerce Packaging Market to Reach US$39.1 Billion by 2033 - Persistenc …

The retail e-commerce packaging market has become a critical pillar of the modern supply chain as online shopping reshapes consumer purchasing behavior worldwide. With the rapid expansion of digital marketplaces direct to consumer brands and omnichannel retail strategies packaging is no longer just a protective medium but a brand touchpoint and sustainability statement. Retail e-commerce packaging includes corrugated boxes mailers protective fillers tapes labels and sustainable packaging formats designed specifically…

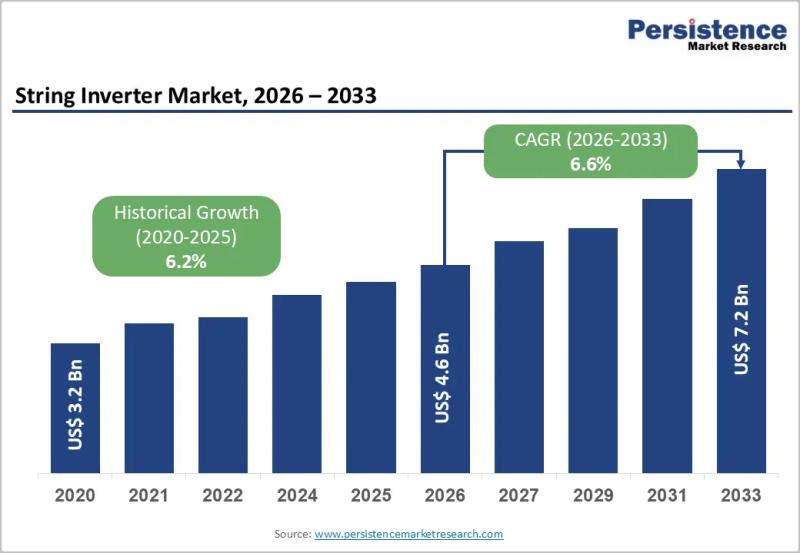

String Inverter Market to Reach US$7.2 Billion by 2033 - Persistence Market Rese …

The string inverter market is emerging as a critical pillar of the global solar photovoltaic ecosystem, supporting the transition toward decentralized renewable energy systems. String inverters play a central role in converting direct current generated by solar panels into usable alternating current for grid connection or onsite consumption. Compared to central inverters, string inverters provide greater design flexibility, easier installation, and improved system monitoring at the string level. Their widespread…

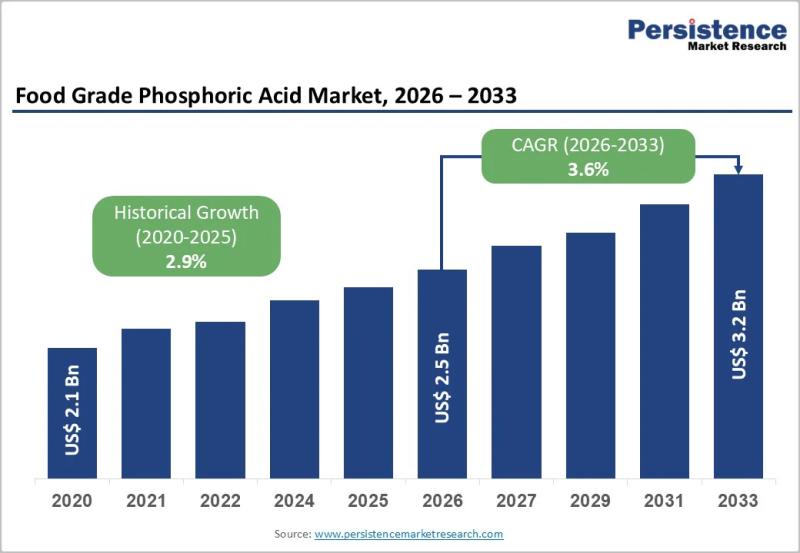

Food Grade Phosphoric Acid Market to Reach US$3.2 Billion by 2033 - Persistence …

The food grade phosphoric acid market plays a critical role in the global food and beverage industry, serving as a key ingredient in acidity regulation, flavor enhancement, preservation, and pH stabilization. Food grade phosphoric acid is widely used in carbonated soft drinks, processed foods, dairy products, bakery formulations, and meat processing applications. Its ability to provide a sharp tangy taste and extend shelf life makes it indispensable for beverage manufacturers…

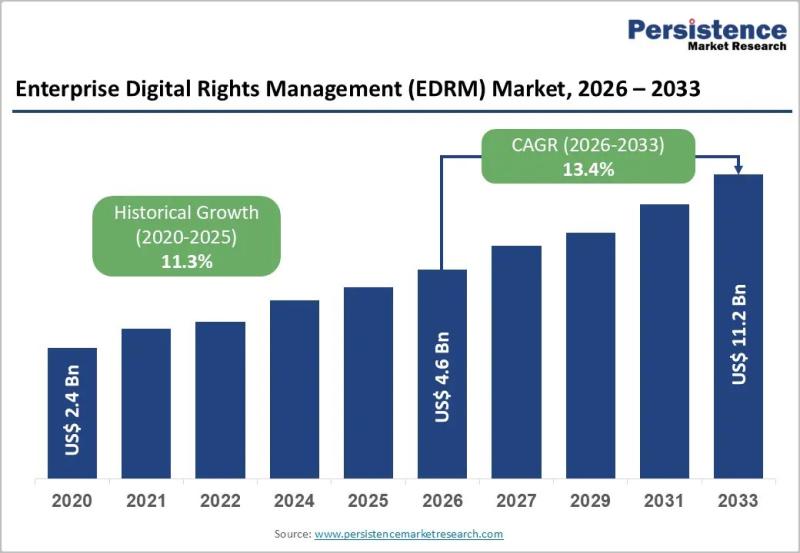

Electronic Document Management System (EDMS) Market to Surpass US$ 27.7 Billion …

The global Electronic Document Management System (EDMS) Market is projected to be valued at US$ 9.7 billion in 2026 and is expected to reach US$ 27.7 billion by 2033, expanding at a robust CAGR of 16.2% during 2026-2033. Organizations worldwide are accelerating digital transformation initiatives by shifting from paper-based processes to intelligent document management platforms. This structural transition is enabling enterprises to enhance workflow automation, improve data governance, and reduce…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…