Press release

How To Setup a Bitumen Manufacturing Plant

Setting up a bitumen manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Bitumen Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a bitumen manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Bitumen is a thick, black, sticky substance made from crude oil. It is produced during the oil refining process. This material is mostly made of hydrocarbons. Bitumen is valued for its waterproof, adhesive, and strong properties. It is key in road construction, roofing, and waterproofing. Its ability to bind materials and resist weather makes it highly effective. Bitumen is also found in products like coatings, adhesives, and sealants. Its low cost, versatility, and durability are essential for infrastructure projects around the world.

The bitumen industry is growing fast. This growth comes from infrastructure development, urbanization, and global road construction. Emerging economies are investing heavily in transportation networks. This increases the demand for bitumen in paving and maintenance. More residential and commercial building also raises its use in waterproofing and roofing. New technologies, like polymer-modified bitumen and warm-mix asphalt, enhance performance and open up new applications.

Request for a Sample Report: https://www.imarcgroup.com/bitumen-manufacturing-plant-project-report/requestsample

Bitumen Manufacturing Plant Project Report Coverage:

1. Market Analysis

The report provides insights into the landscape of the bitumen industry at the global level. The report also provides a segment-wise and region-wise breakup of the global bitumen industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of bitumen, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the bitumen manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=8235&flag=C

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for bitumen manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for bitumen production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a bitumen manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market

demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How To Setup a Bitumen Manufacturing Plant here

News-ID: 3876527 • Views: …

More Releases from IMACR Group

Sodium Lauryl Ether Sulfate Prices Rise Amid Surging Detergent Industry Demand

North America Sodium Lauryl Ether Sulfate (SLES) Prices Movement Q4 2025:

Sodium Lauryl Ether Sulfate (SLES) Prices in United States:

In Q4 2025, sodium lauryl ether sulfate (SLES) prices in the USA averaged USD 812/MT, supported by steady demand from personal care and household cleaning product manufacturers. Stable supply of ethylene oxide and fatty alcohol feedstocks helped maintain balanced production costs. Consistent domestic consumption contributed to relatively stable market conditions.

Get the Real-Time…

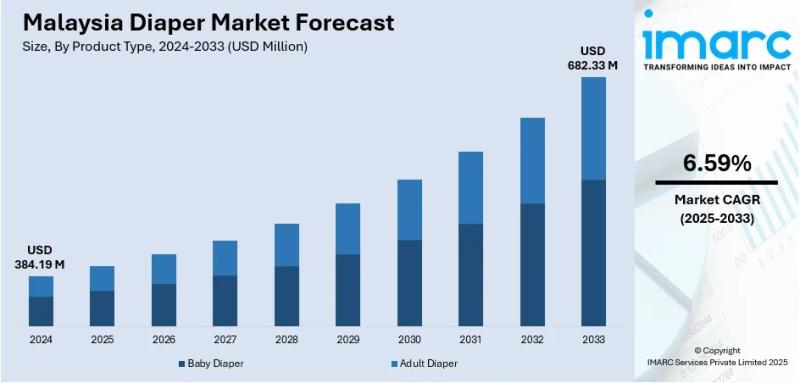

Malaysia Diaper Market to Reach USD 682.33 Million by 2033, Growing at 6.59% CAG …

Source: IMARC Group | Category: Consumer Goods | Author Name: Gaurav

Report Introduction

According to IMARC Group's latest report titled "Malaysia Diaper Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and State, 2025-2033", the market is growing steadily due to the rising awareness regarding infant hygiene and the increasing number of working parents opting for convenient baby care solutions. The study offers a profound analysis of the industry, encompassing…

Mineral Water Processing Plant DPR - 2026: Investment Cost, Market Growth and Ma …

The global beverage and safe drinking water industry is experiencing transformative growth driven by rising awareness regarding safe drinking water, increasing urbanization, growth of the hospitality sector, and higher consumption of packaged beverages. At the forefront of this health and safety revolution stands mineral water-a drinkable water valued for its natural mineral content, consistent quality, and compliance with food safety standards across household consumption, hospitality and tourism sector, healthcare facilities,…

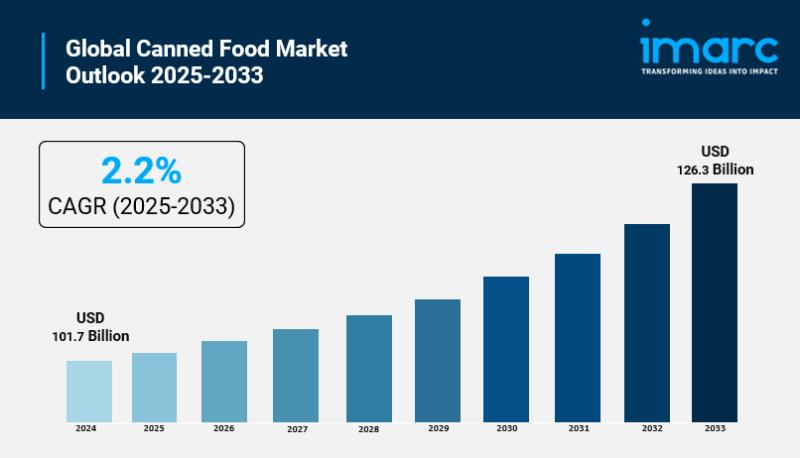

Canned Food Market Size, Share, Latest Insights and Forecast to 2033

IMARC Group, a leading market research company, has recently released a report titled "Canned Food Market Report by Product Type (Canned Meat and Seafood, Canned Fruit and Vegetables, Canned Ready Meals, and Others), Type (Organic, Conventional), Distribution Channel (Supermarkets and Hypermarkets, Convenience Stores, E-commerce, and Others), and Region 2025-2033". The study provides a detailed analysis of the industry, including the canned food market report, growth, size, and industry growth forecast.…

More Releases for Bitumen

U.S. Bitumen Market Trends, Investment Opportunities, and Growth Analysis Throug …

Overview

The "U.S. Bitumen Market 2025 Forecast to 2032" research provides accurate economic, global, and country-level predictions and analyses. It provides a comprehensive perspective of the competitive market as well as an in-depth supply chain analysis to assist businesses in identifying major changes in industry practices. The market report also examines the current state of the U.S. Bitumen industry, as well as predicted future growth, technological advancements, investment prospects, market economics,…

Key Influencer in the Bitumen Market 2025: Growing Road Construction Activities …

How Are the key drivers contributing to the expansion of the bitumen market?

The rise in road construction endeavors is anticipated to boost the advancement of the bitumen market. Activities in road construction encompass the various methods and operations employed in the development, enhancement, and upkeep of roads and highways. Bitumen contributes to these activities by serving as a binder and providing water resistance, flexibility, resistance to weather conditions, skid resistance,…

Netherlands Bitumen Market: 2024, Share & Size Analysis, Growth, Trends, Report …

According to a new report published by CoherentMI The Netherlands Bitumen Market is estimated to be valued at USD 13.81 Bn in 2024 and is expected to reach USD 20.43 Bn by 2031, growing at a CAGR of 4.60% from 2024 to 2031.

Most recent Report, named "Netherlands Bitumen Market" Patterns, Offer, Size, Development, Opportunity and Forecast 2024-2031, by CoherentMI offers a complete investigation of the business, which includes bits of…

bitumen 60/70

What is Bitumen 60/70?

Bitumen 60/70 means penetration of bitumen is between 60 to 70 0.mm. It is produced by blowing hot air onto vacuum bottom residue, resulting in a penetration value of 160 to 220, making it very soft. Heating the raw material can increase its hardness and decrease penetration. This type of bitumen is commonly used in road construction, paving, waterproofing, and coating.

Differences of bitumen 60/70 with bitumen 80/100

Bitumen…

Africa Bitumen Market to Witness Huge Growth by 2028: Royal Dutch Shell Plc., RA …

Description

New Research Study ""Africa Bitumen Market 2022 analysis by Market Trends (Drivers, Constraints, Opportunities, Threats, Challenges and Investment Opportunities), Size, Share and Outlook"" has been added to Coherent Market insight

The Global Africa Bitumen Market 2022 Research Report is a thorough analysis of the Africa Bitumen industry's current state of affairs.

The report gives a fundamental overview of the sector, comprehensive with definitions and classifications. The Africa Bitumen market analysis is offered…

APAC (Asia-Pacific) Bitumen Market Accounted for 31% Volume Share of Global Bitu …

According to Goldstein Research, APAC Bitumen market is expected to reach USD 34.1 billion by the end of 2024, growing at a CAGR of 6.59%. The growing infrastructure projects and maintenance of existing ones are the major driving force in the growing demand for bitumen across the APAC region. APAC Bitumen market segmentation has been done on the basis of grades, product, application, and countries. Road construction accounted for the…