Press release

How to Solve Processing Challenges in Polyethylene Film Manufacturing Without PFAS

What is PE Film and Application?Polyethylene (PE) film is a thin, flexible material manufactured from PE pellets through a process involving extrusion or blown film techniques. This film can possess different properties based on the type of polyethylene used, such as low-density (LDPE), Linear low-density polyethylene(LLDPE), medium-density (MDPE), high-density (HDPE), or cross-linked polyethylene (XLPE).

Polyethylene (PE) films are indispensable in industries like packaging, agriculture, and industrial applications due to their flexibility, durability, and cost-effectiveness. However, manufacturers often face significant processing challenges, such as melt fracture, die build-up, and high extrusion pressures. Traditionally, per- and polyfluoroalkyl substances (PFAS) have been used to address these issues. However, with increasing regulatory restrictions and growing environmental concerns, the industry is shifting toward sustainable, PFAS-free alternatives. [https://www.siliketech.com/fluorine-free-ppa/]

What's Wrong with PFAS? Understanding the Challenges

PFAS chemicals, often referred to as "forever chemicals," have been widely used in industrial applications, including as process aids in polyethylene film manufacturing. Typically, PFAS-based process aids, such as fluoroelastomer additives and PTFE, have long been the go-to solution for improving extrusion efficiency. However, their environmental persistence and potential health risks have led to strict regulations by global authorities like the European Union (EU) and the U.S. Environmental Protection Agency (EPA).

The challenges associated with PFAS include:

1. Environmental Impact: PFAS do not break down naturally, leading to long-term contamination of soil, water, and ecosystems.

2. Regulatory Pressure: Governments worldwide are imposing strict limits or outright bans on PFAS usage, pushing manufacturers to seek alternatives.

3. Consumer Demand: Brands and consumers are increasingly prioritizing eco-friendly and safe products, driving the need for sustainable solutions.

The Shift to PFAS-Free Alternatives

These challenges make it clear that PFAS-based process aids are no longer a viable option for forward-thinking manufacturers. It is now imperative for manufacturers to transition to PFAS-free solutions, they can adopting innovative PFAS-free solutions, such as:

PPA for Polyethylene Functional-Additive Masterbatches [https://www.siliketech.com/fluorine-free-ppa/], PFAS-Free Polymer Process Aids for Film Extrusion, PFAS-Free Solutions for Flexible Packaging, PFAS-Free PPA for Polyolefin Film Extrusion, PFAS-Free PPA for Blown Film Extrusion, PFAS-Free PPA for Cast Film Extrusion, PFAS-Free PPA for Transparent Films, PFAS-Free Food Packaging Solutions (eliminating PFAS from flexible packaging), PFAS-Free Additives for Food Packaging, Fluorine-Free Polymer Processing Aids for Film, PFAS-Free Solutions for Polyolefin Resin, and PFAS-Free Additives for Polyolefin Resin and more...

These PFAS-free alternatives not only address processing challenges but also align with global sustainability goals, and meeting consumer demands for safer, eco-friendly products.

Non-PFAS Process Aids: A Sustainable Alternative You Need to Know

For manufacturers seeking to eliminate per- and polyfluoroalkyl substances (PFAS) while maintaining product performance, SILIKE offers a comprehensive range of PFAS-free processing aid solutions. These solutions are precisely designed to meet the diverse needs of the industry, including 100% pure PFAS-free fluorine-free polymer processing aids and PFAS-free/fluorine-free PPA masterbatches.

However, PFAS free PPA SILIMER 9201 is a processing agent for the extrusion of Polyethylene material with PE as the carrier launched by SILIKE. It is an organic modified polysiloxane masterbatch product, which can migrate to the processing equipment and have an effect during processing by taking advantage of the excellent initial lubrication effect of polysiloxane and the polarity effect of modified groups.

Enter SILIKE PFAS-Free PPA SILIMER 9201, an innovative and eco-friendly processing aid specifically designed for polyethylene film extrusion applications. This Non-PFAS Process Aid for Extrusion Applications leverages cutting-edge polymer technology to address common processing challenges-without relying on PFAS chemicals.

How Does PFAS FREE PPA SILIMER 9201 Solve Your Polyethylene Film Processing Issues?

1. Enhances Resin Flow & Processability - PFAS FREE PPA SILIMER 9201 improves the rheological properties of PE, enhancing smoother processing.

2. Reduces Melt Fracture & Die Build-Up - PFAS FREE PPA SILIMER 9201 prevents film defects and maintains consistent quality.3. Minimizes Downtime & Maintenance Costs - PFAS FREE PPA SILIMER 9201 addresses carbon buildup on screws, barrels, and filters, extending the cleaning cycle and reducing production interruptions.4. Boosts Film Surface Quality - PFAS [https://www.siliketech.com/pfas-free-and-fluorine-free-polymer-processing-aidsppa-silimer-9201-product/]FREE PPA SILIMER 9201 eliminates sharkskin defects, enhances gloss, and improves the overall appearance of films.5. Retains Key Film Properties - PFAS FREE PPA does not affect adhesion, printing, or heat-sealing performance.6. Non PFAS& Environmentally Safe - SILIKE fluoride-free ppa Polymer processing aid. A sustainable alternative to traditional PPA additives, compliance with global regulations.

Applications of Non-PFAS Processing Aids

SILIKE PFAS-Free And Fluorine-Free Polymer Processing Aids(PPA) SILIMER 9201 is versatile and can be effectively utilized in various types of films, including:

1. Flexible Packaging: Improves processability without compromising food safety standards.

2. Blown and Cast Film Extrusion: Enhances efficiency and film quality.

3. Agricultural Films: Ensures durability and performance in demanding environments.

Why Switch to SILIKE PFAS-Free And Fluorine-Free Polymer Processing Aids(PPA) SILIMER 9201?

The regulatory landscape is changing rapidly, and the pressure to adopt sustainable practices is growing. By Introducing SILIKE PFAS-Free And Fluorine-Free Polymer Processing Aids(PPA) SILIMER 9201, you can:

1. Future-Proof Your Operations: Stay ahead of regulatory changes and avoid potential fines or reputational damage.

2. Enhance Efficiency: Reduce downtime, minimize waste, and improve overall productivity.

3. Meet Consumer Demand: Align with the growing preference for eco-friendly and safe products.

One leading packaging film producer shared, "Switching to SILIKE PFAS FREE PPA SILIMER 9201 was a game-changer for us. Not only are we meeting regulatory requirements, but we're also seeing improved film quality and cost savings. It's a win-win for our business and the environment."-because innovation and sustainability go hand in hand.Chengdu SILIKE Technology Co., Ltd is a trusted leader in silicone additives and PFAS-free PPAs, offering cutting-edge solutions to elevate the performance of your plastic materials.Request a Sample Now and discover how SILIKE PFAS-Free And Fluorine-Free Polymer Processing Aids(PPAs) [https://www.siliketech.com/fluorine-free-ppa/]can transform your packaging films while supporting your sustainability goals.Contact us at amy.wang@silike.cn, or Visit our website: www.siliketech.com to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=how-to-solve-processing-challenges-in-polyethylene-film-manufacturing-without-pfas]

Country: China

Website: https://www.siliketech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Solve Processing Challenges in Polyethylene Film Manufacturing Without PFAS here

News-ID: 3871970 • Views: …

More Releases from ABNewswire

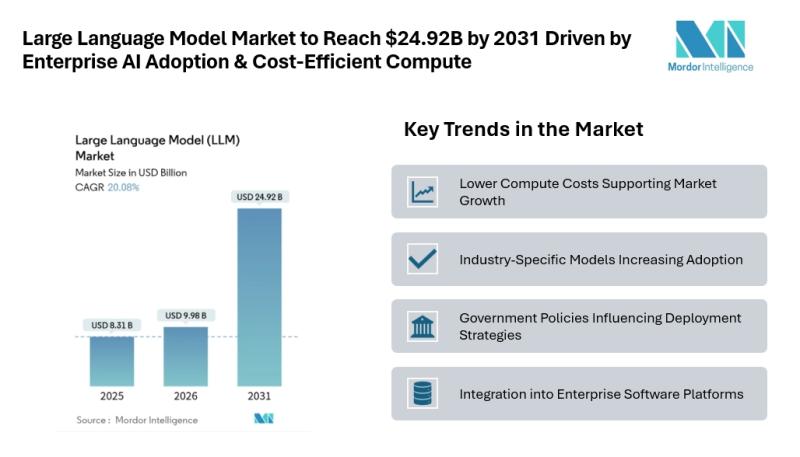

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

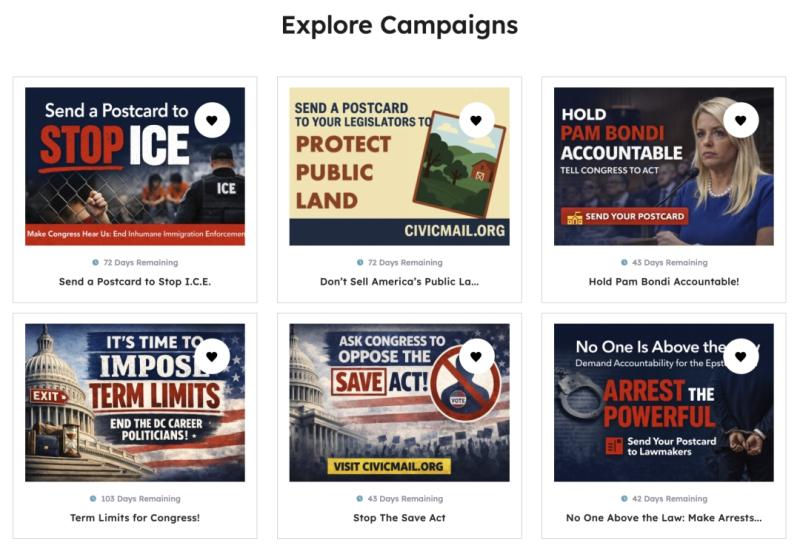

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for PFAS

PFAS Remediation Market Is Going to Boom |• AquaBlok • Arcadis

Worldwide Market Reports has released a new in-depth research study on the "PFAS Remediation Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities, technological advancements, innovation trends,…

PFAS-Free Synthetic Turf Solutions | Eco-Friendly Artificial Grass and Non-PFAS …

This article delves into the key challenges and difficulties faced by the synthetic turf industry in achieving a "PFAS-free" transition, with a focus on innovative non-PFAS additive solutions designed to offer a sustainable path that balances high performance, safety, and environmental responsibility.

Challenges in Traditional Synthetic Turf Manufacturing | PFAS Risks Performance vs. Safety Dilemma

Traditional synthetic turf often relies on fluorinated polymers to achieve:

- Exceptional UV and weather durability

- Stain and…

Global PFAS-free Membranes Market Outlook Report 2025

Global Info Research's report is a detailed and comprehensive analysis for global PFAS-free Membranes market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the PFAS-free Membranes market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of…

PFAS-free Polymer Membranes Market Demand Analysis Report 2025

Global Info Research announces the release of the report "Global PFAS-free Polymer Membranes Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides a detailed overview of the PFAS-free Polymer Membranes market scenario, including a thorough analysis of the PFAS-free Polymer Membranes market size, sales quantity, average price, revenue, gross margin and market share.The PFAS-free Polymer Membranes report provides an in-depth analysis of the competitive landscape,…

PFAS-free Polymer Processing Aids (PFAS-Free PPA Additives), a solution to the p …

In the plastic processing industry, die build-up is a common problem that can lead to surface defects in products, affecting product quality and production efficiency.

Die build-up refers to the accumulation of material at the outlet of the mold during plastic processing, forming deposits that are difficult to remove. This phenomenon usually occurs in injection molding, extrusion and other processes, especially in the processing of high viscosity and high melting point…

PFAS: What they are & how to avoid them

These "Forever Chemicals" have existed for what seems like forever, but they've just recently begun making headlines. Here's what you need to know about these troubling compounds.

In the world we live in today, the alphabet soup of acronyms for both good and bad substances can make your brain feel like mush. But there's one that you've probably seen popping up more and more. And it's one worth remembering.

PFAS, or "Forever…