Press release

Factors behind Ultrasonic Cleaner durability: How to extend its lifespan

Ultrasonic cleaners [https://www.china-tense.net/cabinet-spray-parts-washer-product/] are essential machine in both industrial and laboratory cleaning, known for their high efficiency and fast cleaning capabilities. Despite their advantages, many users have reported that these machines tend to be relatively "fragile" over time, often experiencing malfunctions or even breakdowns. This leads to a reduction in productivity, increased repair costs, and sometimes impacts cleaning performance. Understanding the root causes of ultrasonic cleaner wear is crucial for extending the lifespan of these devices and minimizing failure rates.Key Factors Contributing to Ultrasonic Cleaner Wear

An ultrasonic parts cleaner [https://www.china-tense.net/digital-control-ultrasonic-cleaning-machine-product/] consists of several critical components, including the transducer, cleaning tank, electrical system, and control module. These components are subject to a variety of stressors in high-frequency, high-power environments, leading to wear and potential damage. Below, we explore the most common causes of wear and failure in ultrasonic cleaners.

1. Transducer Failures

The transducer plays a pivotal role in ultrasonic cleaning by converting electrical energy into mechanical vibrations, generating ultrasound waves. However, due to prolonged high-frequency and high-power operation, transducers are particularly prone to failure.

Overheating: The transducer generates significant heat during operation, and without an effective cooling mechanism, excessive temperatures can degrade the transducer's piezoelectric material, causing cracks or even delamination.

Frequent Start-Stop Cycles: Each time the machine is powered on or off, the transducer undergoes rapid vibration changes. Repeated cycles of this kind over time can result in internal fatigue, making the component more vulnerable to damage.

Physical Damage: External shocks or mechanical vibrations can compromise the internal structure of the transducer, affecting its stability and causing inconsistent ultrasonic output.

2. Wear and Corrosion of the Cleaning Tank

Although cleaning tanks are typically made of materials like stainless steel that are resistant to corrosion, they still face wear and tear from long-term exposure to high-frequency vibrations and chemical cleaning agents.

Cavitation Erosion: Cavitation, the process where tiny bubbles implode within the liquid, is central to the ultrasonic cleaning process. While it is effective at removing contaminants, cavitation also impacts the inner surfaces of the cleaning tank, causing microcracks or holes over time, which can ultimately lead to the tank failing.

Chemical Corrosion: Many industrial cleaning tasks require the use of acidic or alkaline cleaning solutions. These solutions, when combined with ultrasonic vibrations, can hasten the corrosion of the cleaning tank. Though stainless steel is somewhat resistant, prolonged exposure to strong chemicals can still result in oxidation or material degradation.

3. Electrical System Failures

The electrical system of an cabinet ultrasonic cleaner [https://www.china-tense.net/cabinet-spray-parts-washer-product/] is complex, responsible for controlling the power output, frequency, and other parameters. Failures within the electrical system are a major source of equipment malfunction.

Overload: If the machine's power output exceeds the system's design capacity, the electrical system may become overloaded, causing circuit boards or other electronic components to burn out.

Frequency Mismatch: The frequency of the ultrasonic cleaner is regulated by oscillation circuits on the circuit board. If these circuits malfunction or become imbalanced, it may prevent the transducer from generating a stable frequency, which in turn affects cleaning efficiency.

Aging Components: Over time, the electronic parts of the system degrade, especially under conditions of sustained high temperatures. This degradation reduces insulation performance, which can lead to short circuits or component failures.

4. Improper Usage

Aside from equipment malfunctions, improper operation is a key factor in the wear and tear of ultrasonic cleaners. Incorrect usage can not only diminish cleaning effectiveness but also increase the risk of equipment damage.

Low Liquid Levels: If the liquid in the cleaning tank is too low, the transducer's vibrations may not be properly cushioned, causing it to operate under stress and potentially leading to damage.

Inappropriate Cleaning Solutions: Using cleaning agents that are too acidic or alkaline, or incompatible with the cleaner's materials, can accelerate internal corrosion, increasing wear and reducing the device's overall lifespan.

Excessive High-Power Operation: Running the ultrasonic cleaner at full power for extended periods can speed up wear on both the transducer and the cleaning tank, causing premature aging of the equipment and raising maintenance costs.

Methods to Extend the Lifespan of Ultrasonic Cleaners

Although ultrasonic cleaners do experience some natural wear, adopting the following preventive measures can significantly extend their operational life.

1. Regular Inspections and Maintenance

Check Transducers: Periodically inspect the transducers for overheating, cracks, or abnormal vibrations. Promptly replace or repair any defective transducers to maintain efficient operation.

Inspect Cleaning Tank: Regularly examine the cleaning tank for signs of corrosion, cracks, or holes. Use gentle cleaning agents and avoid harsh chemicals to prevent unnecessary damage.

Electrical System Checks: Ensure that the power cables, plugs, and internal circuits are in good condition. Conduct regular checks on the power output and frequency, and avoid overloading the device, especially during high-power operation.

2. Control the Operating Environment

Ensure Adequate Ventilation: Keep the working environment well-ventilated to prevent overheating of both the transducer and electrical system. Installing additional cooling devices may help lower temperatures and improve device longevity.

Prevent Physical Damage: Avoid placing the equipment in areas prone to external shocks or vibrations to protect the transducer and tank from damage.

3. Proper Use of the Equipment

Adjust Power and Usage Time: Avoid prolonged high-power operation. Adjust power settings based on cleaning needs, and consider using the machine intermittently for extended cleaning tasks to reduce wear on the transducer.

Use Appropriate Cleaning Solutions: Choose cleaning agents that are compatible with the machine's material. Ensure that the cleaning liquid level is within the recommended range to avoid dry running, which can damage the transducer.

4. Maintain Detailed Records

Keep detailed records of all maintenance activities, including inspections, repairs, and replacements. This documentation helps track the machine's condition and allows users to identify potential issues early.

Conclusion

Ultrasonic cleaner wear and tear can be attributed to several factors, including transducer failures, tank degradation, electrical system malfunctions, and improper usage. While some degree of wear is inevitable, proper care and regular maintenance can substantially extend the lifespan of these devices. For frequent users, maintaining the equipment in optimal condition not only boosts cleaning efficiency but also minimizes downtime and repair costs.

Media Contact

Company Name: Shanghai Tianshi Electromechanical Equipment Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=factors-behind-ultrasonic-cleaner-durability-how-to-extend-its-lifespan]

Country: China

Website: https://www.china-tense.net/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Factors behind Ultrasonic Cleaner durability: How to extend its lifespan here

News-ID: 3865798 • Views: …

More Releases from ABNewswire

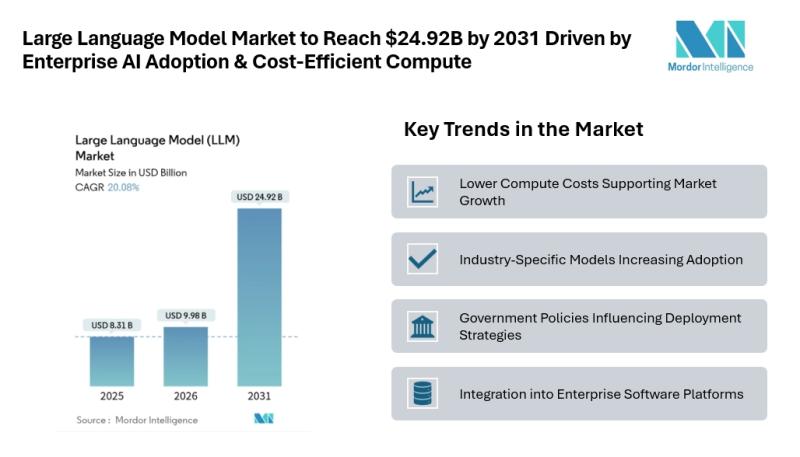

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

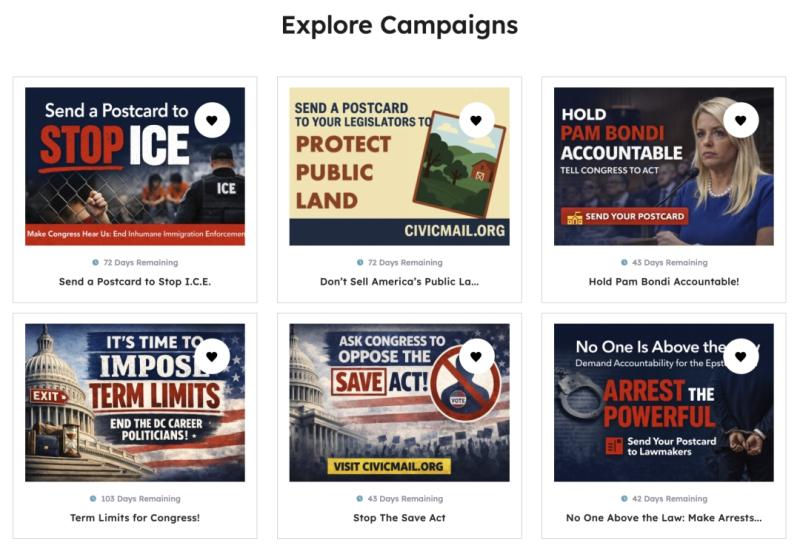

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for Ultrasonic

Ultrasonic Cleaning Market Report 2024 - Ultrasonic Cleaning Market Demand And S …

"The Business Research Company recently released a comprehensive report on the Global Ultrasonic Cleaning Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

Ultrasonic Gas Leak Detectors and Ultrasonic Gas Detector Machine Services | SM …

SM INSTRUMENTS provides ultrasonic gas leak detectors and ultrasonic gas detector machine services. They are Korea's leading provider of ultrasonic equipment and services, and their ultrasonic gas leak detectors are some of the most reliable and accurate on the market.

SM Instruments Ultrasonic Gas Leak Detectors

SM Instruments ultrasonic gas leak detectors use ultrasonic technology to detect gas leaks. Ultrasonic waves are sound waves that are above the range of human hearing.…

Ultrasonic Oxygen Sensor Market, Ultrasonic Oxygen Sensor Market Size, Ultrasoni …

Fairfield Market Research offers a complete understanding of the Global Ultrasonic Oxygen Sensor Market in its latest research report. The report includes an unbiased analysis of the market dynamics. The report covers growth prospects, market development potential, product profitability, supply and demand curves and predictions, and government policies. The report has been put together using reliable tools to assess the primary and secondary data. The data is represented in the…

Lithium Battery Ultrasonic Welding Machine Market Booming Worldwide( Forecast Pe …

The global Lithium Battery Ultrasonic Welding Machine market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Lithium Battery Ultrasonic Welding Machine market. For instance, the market dynamics section digs deep into the drivers, restraints,…

Ultrasonic Water Meter Market Ultrasonic Water Meter Market

The proposed Ultrasonic Water Meter Market report will encompass all the qualitative & quantitative aspects including the market size, market estimates, growth rates & forecasts & hence will give you a holistic view of the market. The study also includes detailed analysis of market drivers, restraints, technological advancements & competitive landscape along with various micro & macro factors influencing the market dynamics.

The Ultrasonic Water Meter Market sample report…

Global Ultrasonic Welder Market 2017 - Rinco, Maxwide Ultrasonic, Kormax System

The report entitled Global Ultrasonic Welder Market 2017 presents key insights into the global Ultrasonic Welder market along with the latest up-to-date industry details and forthcoming Ultrasonic Welder industry trends, which will assist the readers to focus on product specification and end users driving the overall market revenue and profitability.

Report Keynotes:

The main motive of the report on "Global Ultrasonic Welder Market 2017" is to study comprehensive details of the market…