Press release

Silicone Processing Aids For Wire & Cables compounds: how to solve the situation of rough surface of cable material, pre-crosslinking and uneven dispersion of filler?

In the modern industrial system, cable as a key carrier of power transmission and information transmission, its quality is directly related to the stable operation of various fields. The cable material, as the core raw material of cable manufacturing, its performance and processing quality play a decisive role.Cable material is used to manufacture wire and cable polymer material, mainly divided into plastic and rubber two categories. Plastic cable materials such as polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), etc., have good insulation, corrosion resistance and processing properties; Rubber cable materials such as natural rubber, ethylene propylene rubber, etc., are known for their high elasticity, weather resistance and flexibility. These materials are widely used in power, communication, construction, automotive and many other fields, from daily household electricity to complex industrial control systems, from high-speed network communication to the electrical system of new energy vehicles, cable materials are everywhere, supporting the normal operation of modern society.

However, in the actual processing process, the cable material often appears rough surface and shark skin phenomenon, which not only seriously affects the appearance quality of the cable, but also may cause the electrical performance of the cable to decline due to surface defects, such as reduced insulation performance, signal transmission instability, etc., and then pose a threat to the safety and reliability of the entire system.

Why will the surface roughness and shark skin appear in the processing of the cable material?

Uneven dispersion of fillers and improper use of additives will result in uneven material surfaces, especially under the situation of high filling materials system. At the same time, inappropriate processing temperature, pressure or speed may cause the material to flow unevenly during processing, resulting in the formation of rough surfaces.

How to solve the situation of rough surface of cable material, pre-crosslinking and uneven dispersion of filler?

SILIKE SILICONE MASTERBATCH LYSI 401 [https://www.siliketech.com/silicone-powder-for-wire-cable/] is a special processing additive for cable materials. Its effective ingredient is ultra-high molecular weight polysiloxane, which can significantly improve the processing fluidity of cable materials, promote the dispersion of filler, improve the shark skin phenomenon, and also improve the properties of wear resistance, scratch resistance and the cable surface quality.

SILIKE Silicone Processing Aids For Wire&Cables compounds has a wide range of applications, they are widely used in LSZH/HFFR wire and cable compounds, silane crossing linking XLPE compounds, TPE wire, Low smoke & low COF PVC compounds. Making wire and cable products eco-friendly, safer, and stronger for better end-use performance.

As a high performance processing aid, SILIKE Silicone Masterbatch has a remarkable effect on improving the surface quality of cable material. Silicone masterbatch has the following advantages:

Excellent lubrication properties: SILIKE Silicone Masterbatch for Wire&Cables compounds can significantly reduce the surface tension of the cable material, making it smoother during the extrusion process, reducing the appearance of surface roughness and shark skin phenomenon.

Improve processing stability: SILIKE Silicone masterbatch LYSI-401 can improve the flow of cable material, making the distribution of cable material in the extruder more uniform, thereby improving the stability of the processing process.

Enhanced product performance: After adding silicone masterbatch LYSI-401, the surface quality of the cable material is significantly improved, which not only improves the appearance quality of the cable, but also enhances the surface wear resistance and scratch resistance of the cable material.

In short, the phenomenon of rough surface and shark skin in the processing of cable materials is the result of a variety of factors. As an effective additive, silicone masterbatch can provide strong support for the development of the cable industry by improving the processing performance and surface quality of the cable material.

Chengdu SILIKE Technology Co., Ltd, a Chinese leading Silicone Additive Supplier for modified plastic, offer innovative solutions to enhance the performance and functionality of plastic materials. Welcome to contact us, SILIKE will provide you with efficient plastics processing solutions.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn

website: www.siliketech.com [https://www.siliketech.com/] to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=silicone-processing-aids-for-wirecables-compounds-how-to-solve-the-situation-of-rough-surface-of-cable-material-precrosslinking-and-uneven-dispersion-of-filler]

Country: China

Website: https://www.siliketech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Silicone Processing Aids For Wire & Cables compounds: how to solve the situation of rough surface of cable material, pre-crosslinking and uneven dispersion of filler? here

News-ID: 3865793 • Views: …

More Releases from ABNewswire

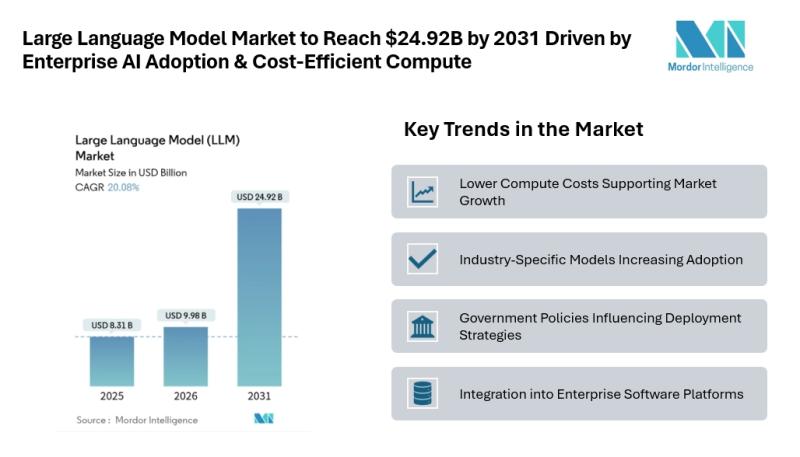

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

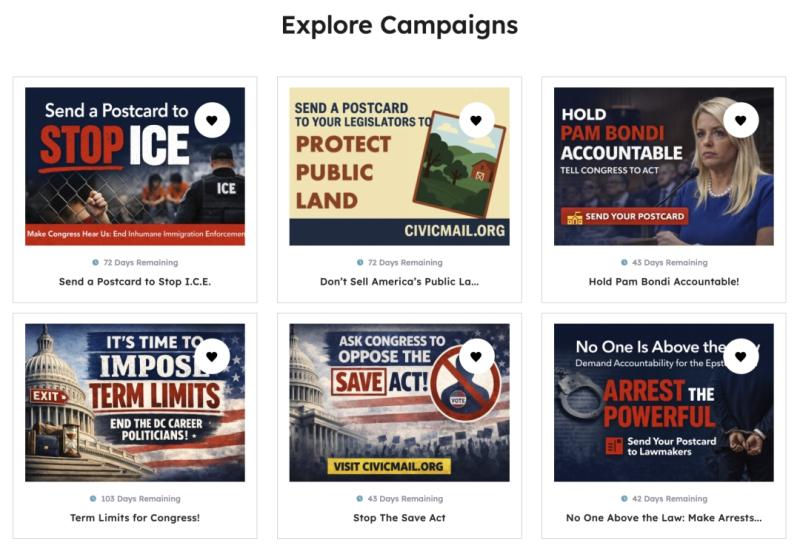

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for Silicone

Revolutionizing Industries: Tenchy Silicone Introduces Cutting-Edge Silicone Tub …

Shenzhen Tenchy Silicone And Rubber Co., Ltd, a renowned leader in silicone products manufacturing, proudly announces the launch of its advanced silicone tubing solutions. Designed to meet the diverse needs of industries such as medical, automotive, and food and beverage, these innovative products represent a significant step forward in silicone technology.

In a world where reliability, performance, and versatility are paramount, silicone tubing stands out as a material of choice for…

Five common properties of silicone and the primary Types of Silicone

Silicones are a versatile class of polymers that come in various forms, offering immense potential for customization to meet the precise needs of the medical and aerospace sectors. Their characteristics enable them to perform diverse functions, such as sealing, lubricating, and fulfilling a host of other tasks.

Silicone's versatility is attributed to its unique physical and mechanical properties, which make it a valuable material in various industries. This article will delve…

Tenchy Silicone: Quality Silicone Tube Supplier for Different Industries

Tenchy Silicone is proud to announce the opening of their new headquarters, which will provide a quality silicone tube supplier service to different industries and businesses. Their silicone tubes are made from FDA-approved materials and are temperature resistant up to 230 degrees Celsius. All products come with an assurance of quality from Tenchy Silicone's team of experienced engineers and technicians who ensure that each product meets customer needs and specifications.…

Tenchy Silicone introducing new silicone foam strip

Tenchy Silicone, the leading provider of high-quality silicone foam strip, is proud to announce their newest product. The Silicone Foam Strip features a combination of both closed-cell and open-cell foaming technologies which offers outstanding thermal insulation and water resistance properties as well as superior airtight performance. It also provides excellent cushioning for equipment, machinery, components and instruments to ensure protection from dust, moisture, abrasion and shock. In addition to its…

Tenchy Silicone Announces Expansion on Silicone Tube Supplier Selection

Tenchy Silicone, a leading silicone tube supplier, is pleased to announce the expansion of its selection of products and services for customers. With over ten years of experience in the industry, the company has established a reputation for providing top-quality silicone tubes that meet customer needs and expectations. The new product line includes tubing from various manufacturers and offers a wide range of materials and sizes to accommodate every project.…

Tenchy Silicone Unveils their New Silicone Seal Gasket

Tenchy Silicone recently released a new silicone seal gasket designed to be used in a variety of industrial applications. It also provides excellent temperature insulation thanks to its ability to withstand temperatures up to 260 °C without any deformation or loss of strength, making it ideal for large-scale industrial projects. The silicone seal gasket is also unaffected by chemicals and ultraviolet light, making it suitable for numerous industries including automotive,…