Press release

AI Integration Boosting Efficiency in Thermoform Packaging

The global thermoform packaging market is witnessing significant growth and is projected to reach USD 93 billion by 2034, up from USD 52.4 billion in 2024. This represents an impressive compound annual growth rate (CAGR) of 5.9% from 2024 to 2034, driven by innovation, increased demand, and evolving consumer preferences across industries.Download a Brochure of Thermoform Packaging Market: https://www.towardspackaging.com/download-brochure/5089

Understanding Thermoform Packaging

Thermoform packaging, a vital segment within the larger packaging industry, utilizes a specialized manufacturing process known as thermoforming. In this process, a plastic sheet is heated until it reaches a malleable temperature. It is then shaped within a mold and cooled to form the final product. This method is incredibly versatile, allowing manufacturers to create a wide variety of packaging solutions, including blister packs, clamshells, trays, and containers of all sizes and shapes.

The flexibility of thermoforming has made it an attractive option for industries that require highly customizable packaging, offering tailored solutions to meet specific design and functionality needs. Among the most commonly used materials in thermoform packaging are polyethene, polypropylene, and polystyrene, each providing distinct advantages depending on the product and market requirements. This adaptability makes thermoform packaging a preferred choice for manufacturers in the food and beverage, pharmaceuticals, electronics, and retail sectors.

Key Drivers of Growth

The primary driver of growth in the thermoform packaging market is its adaptability. As businesses seek ways to optimize packaging for efficiency, cost-effectiveness, and aesthetics, thermoform packaging proves to be an excellent solution. Custom-designed packaging enhances product visibility, improves branding, and ensures product safety, making it a popular choice for a wide range of products.

Technological advancements are another significant factor contributing to the growth of this market. The integration of robotics and automation into the thermoforming process has led to improvements in precision, speed, and efficiency, resulting in high-quality packaging solutions at a faster rate. The ability to quickly and accurately produce complex designs has enabled manufacturers to meet increasing demand while ensuring quality and performance.

Sustainability: A Rising Trend

Sustainability is a growing concern for businesses and consumers alike, and the thermoform packaging industry is responding to this trend with increasing focus on eco-friendly solutions. Manufacturers are exploring alternative materials that are recyclable, biodegradable, or produced through sustainable methods, reducing the environmental impact of packaging products.

The European plastics industry has taken a proactive approach by setting ambitious goals for the future, including increasing plastic recycling and reuse by up to 60% by 2030. This initiative is part of a broader strategy to develop more sustainable packaging solutions, aligning with the global push toward reducing plastic waste and supporting circular economies.

The Role of Design and Innovation

As the market evolves, one of the most notable developments in thermoform packaging is the ongoing innovation in design and graphics. Advances in 3D modeling, virtual prototyping, and other design technologies have enabled manufacturers to push the boundaries of what's possible in packaging aesthetics. This not only enhances the functionality of packaging but also improves its visual appeal.

For brands looking to differentiate themselves in a competitive marketplace, packaging design has become an essential element of product marketing. By utilizing thermoform packaging, companies can create unique, visually striking packaging that draws consumer attention, conveys quality, and enhances the overall product experience.

Applications Across Industries

Thermoform packaging is increasingly being adopted across multiple industries. In the food and beverage sector, its ability to offer lightweight, protective, and customizable packaging for various products, from fresh produce to snacks, makes it highly valuable. Pharmaceuticals also rely on thermoform packaging for the secure and hygienic packaging of medicines, ensuring that sensitive products are well protected during transport and storage.

The electronics industry has found thermoform packaging beneficial for safely housing delicate components, ensuring they are shielded from physical damage and environmental factors. Retailers are using thermoform packaging for everything from cosmetic packaging to retail displays, with its transparency allowing consumers to easily view the product inside.

The Future of Thermoform Packaging

As the demand for efficient, sustainable, and innovative packaging continues to grow, the thermoform packaging market is expected to expand even further. The combination of technological advancements, sustainability efforts, and a focus on design will drive the future of the industry, ensuring its continued success.

With its versatile manufacturing process, customizability, and growing focus on eco-friendly practices, thermoform packaging is poised to remain a vital and growing component of the global packaging industry. As manufacturers continue to innovate and respond to market demands, the future of thermoform packaging looks bright, with new applications and opportunities emerging across diverse industries.

The Role of AI Integration in the Thermoform Packaging Market: Paving the Way for a Smarter Future

The rise of Artificial Intelligence (AI) is a defining force reshaping industries across the globe, and the thermoform packaging sector is no exception. Thermoform packaging, which utilizes a heating and molding process to create plastic containers, trays, and other packaging solutions, is becoming increasingly sophisticated with the incorporation of AI. This integration is not just enhancing production efficiency but is fundamentally transforming the way packaging is designed, produced, and delivered. With the help of AI, manufacturers are optimizing operations, reducing costs, increasing scalability, and pushing the boundaries of customization in ways that were previously unimaginable.

Unveiling the Power of AI in Thermoform Packaging

Thermoform packaging relies on a highly precise manufacturing process in which a plastic sheet is heated, formed into a mold, and then cooled to create packaging products like blister packs, clamshells, trays, and containers. The adoption of AI is helping to streamline every phase of this process-from design and production to quality control and maintenance-leading to greater efficiency, improved product quality, and cost savings.

At the core of this transformation is the use of advanced AI technologies such as machine learning, predictive analytics, and real-time data processing. By tapping into vast amounts of data generated across production lines, AI enables manufacturers to make informed decisions, implement process improvements, and ensure that every packaging unit meets the highest standards.

AI for Predictive Maintenance: Reducing Downtime and Preventing Disruptions

One of the most impactful applications of AI in the thermoform packaging industry is predictive maintenance. Traditionally, equipment failures in manufacturing lines were unpredictable and often resulted in expensive downtimes, causing delays and increasing operational costs. However, with AI-driven predictive maintenance, manufacturers can foresee potential issues with machinery and address them before they lead to significant disruptions.

By using data collected from sensors embedded in machinery, AI systems can continuously monitor the health of production equipment and detect subtle anomalies that might indicate wear and tear. These systems then alert operators to potential problems, allowing them to perform maintenance or make adjustments proactively. As a result, production lines experience less downtime, leading to smoother operations and higher throughput. The increased reliability of equipment also contributes to more efficient resource usage and reduced operational costs.

Streamlining the Manufacturing Process with AI Optimization

AI's potential goes beyond just maintenance; it is playing a central role in optimizing the entire thermoforming manufacturing process. By using AI to analyze real-time data, manufacturers can dynamically adjust critical parameters like temperature, pressure, and speed during the production of packaging. This precise control helps to ensure that each thermoform packaging unit is produced with high levels of consistency and quality, reducing the likelihood of defects and material waste.

AI can also identify inefficiencies within the production process, whether they relate to equipment usage, production speed, or material consumption. By analyzing production data across multiple cycles, AI-driven systems can identify bottlenecks or underperforming equipment, and suggest adjustments to improve overall throughput. This data-driven approach leads to continuous improvements in the production process, increasing productivity and reducing the environmental footprint of packaging production.

For example, AI can suggest modifications to the thermoforming temperature to enhance the strength and durability of packaging, ensuring better protection for products while also minimizing the amount of raw material used. This not only results in cost savings but also aligns with the growing emphasis on sustainable manufacturing practices.

Enhancing Customization and Complex Solutions

One of the most exciting aspects of AI integration in thermoform packaging is its ability to support highly customized and complex packaging designs. Traditional thermoform packaging often relied on pre-designed templates or simple configurations that were efficient but lacked flexibility. However, with AI-powered design tools, manufacturers can now produce intricate, bespoke packaging solutions tailored to the unique needs of each product.

AI algorithms can simulate and optimize designs in a virtual environment, adjusting dimensions, materials, and structural elements based on product specifications, regulatory requirements, and environmental concerns. By using 3D modeling and virtual prototyping, manufacturers can test multiple designs before production begins, reducing costly trial and error and ensuring that the final packaging meets both functional and aesthetic requirements.

Moreover, AI can help with material selection by analyzing data on the properties of different plastic materials, taking into account factors such as cost, strength, recyclability, and environmental impact. As sustainability becomes an increasingly important factor in consumer purchasing decisions, AI's ability to optimize packaging for eco-friendliness is crucial for staying competitive in the market.

Scaling Production and Reducing Labor Costs

AI's influence also extends to the scalability of thermoform packaging production. As demand for packaging solutions grows, manufacturers need to ramp up production quickly and efficiently to meet the needs of a rapidly evolving market. AI enables the seamless scaling of production capabilities by automating routine tasks, managing production schedules, and adjusting parameters to accommodate larger volumes of orders without sacrificing quality.

By automating repetitive tasks such as quality inspections, packaging assembly, and material handling, AI reduces the dependency on manual labor, lowering labor costs. This automation also ensures that packaging production can be scaled up swiftly to meet seasonal demand surges or accommodate the introduction of new product lines. As AI continues to advance, these systems will only become more intelligent, capable of handling even more complex production requirements with minimal human intervention.

Real-Time Monitoring and Quality Control

AI technologies also play a critical role in real-time monitoring and quality control throughout the thermoform packaging production process. High-speed cameras and sensors, powered by AI, are used to inspect packaging for defects, such as misalignment, damage, or inadequate sealing. These systems can detect flaws at speeds far greater than human workers, ensuring that every piece of packaging meets the required quality standards before it reaches the customer.

By automating quality control, AI reduces the likelihood of errors and increases production consistency. The real-time monitoring systems can immediately identify when something goes wrong, allowing operators to adjust the production process on the fly. This level of oversight helps maintain the highest standards in packaging design, contributing to better product protection, enhanced brand image, and greater consumer satisfaction.

Source: https://www.towardspackaging.com/insights/thermoform-packaging-market-size

Baner

Buy Premium Global Insight: https://www.towardspackaging.com/price/5089

Review the Full TOC for the Thermoform Packaging Market Report: https://www.towardspackaging.com/table-of-content/thermoform-packaging-market-size

Get the latest insights on packaging industry segmentation with our Annual Membership - https://www.towardspackaging.com/get-an-annual-membership

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

Towards Healthcare: https://www.towardshealthcare.com

Towards Automotive: https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AI Integration Boosting Efficiency in Thermoform Packaging here

News-ID: 3819365 • Views: …

More Releases from Towards Packaging

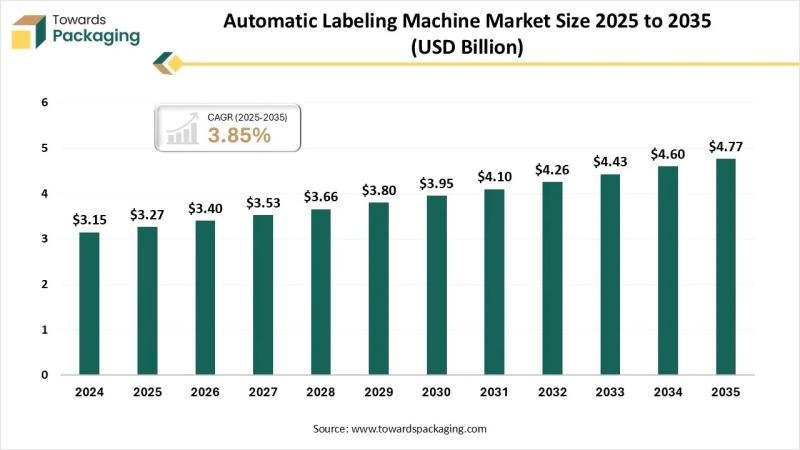

Automatic Labeling Machine Market Set for Strong Growth Through 2035

The global automatic labeling machine market is poised for steady expansion, rising from USD 3.4 billion in 2026 to USD 4.77 billion by 2035 at a CAGR of 3.85%. Demand is being driven by rapid automation in packaging lines, stringent labeling regulations, and the shift toward high-speed, error-free production across industries.

Download Sample: https://www.towardspackaging.com/download-sample/5882

Self-adhesive labeling systems currently hold the largest share at 39%, supported by their versatility and cost efficiency. Meanwhile,…

Unleashing Growth in the Liquid Packaging Market with Strategic Innovations

The liquid packaging industry is experiencing remarkable growth, with projections indicating an increase from USD 397.36 billion in 2025 to USD 645.43 billion by 2034. This growth, at a compound annual growth rate (CAGR) of 5.7%, signifies the expanding demand for liquid packaging solutions across a variety of sectors. As we delve into the market dynamics, it becomes clear that the liquid packaging sector is evolving rapidly, with several key…

Advancements in Hot-Fill Food Packaging Paving the Way for a Sustainable Future

The global hot-fill food packaging market is experiencing a steady rise, with an expected market value of USD 71.26 billion by 2033, up from USD 49.85 billion in 2023. This growth is projected to follow a compound annual growth rate (CAGR) of 3.76% from 2024 to 2033, reflecting the increasing demand for innovative packaging solutions in the food and beverage sector.

Download a Brochure of Hot-fill Food Packaging Market: https://www.towardspackaging.com/download-brochure/5266

Hot-Fill…

Driving Growth and Innovation in the Plastic Bag Market

The plastic bag market is undergoing significant growth, with its value reaching an estimated US$ 25.10 billion in 2023. Projections suggest that this market could hit a substantial US$ 35.41 billion by 2033, marking a steady compound annual growth rate (CAGR) of 3.5% from 2024 to 2034. This growth is largely driven by the expanding needs of various industries for efficient and cost-effective packaging solutions.

Download a Brochure of Plastic Bag…

More Releases for Thermoform

Thermoform Packaging Market Know the Scope and Trends

"Thermoform packaging Market" in terms of revenue was estimated to be worth $51.93 billion in 2023 and is poised to reach $83.25 billion by 2031, growing at a CAGR of 6.25% from 2023 to 2031, according to a new report by InsightAce Analytic.

Request for Sample Pages:

https://www.insightaceanalytic.com/request-sample/1583

Latest Drivers Restraint and Opportunities Market Snapshot:

Key factors influencing the global thermoform packaging market are:

• Changes in consumer preferences and the growing urban…

Thermoform Packaging Market in 2024 Detailed Study Analysis

"Thermoform packaging Market" in terms of revenue was estimated to be worth $51.93 billion in 2023 and is poised to reach $83.25 billion by 2031, growing at a CAGR of 6.25% from 2023 to 2031, according to a new report by InsightAce Analytic.

Request for Sample Pages: https://www.insightaceanalytic.com/request-sample/1583

Latest Drivers Restraint and Opportunities Market Snapshot:

Key factors influencing the global thermoform packaging market are:

• Changes in consumer preferences and the growing urban…

Thermoform Packaging Market Player Profiling, Forecast till 2032

According to Ameco Research 'Thermoform Packaging Market report, the analysts took this into account when estimating the Thermoform Packaging Market size and CAGR for the respective industry. The report's author has thoroughly examined the market and concluded that the Thermoform Packaging Market 's growth will level off in the coming years. In addition to that, the prominent qualitative information added in the report includes Thermoform Packaging Market trends, segmentation, key…

Thermoform Packaging Market Size, CAGR | Growth - 2030

Exclusive Report by Ameco Research: Thermoform Packaging Market Size Projected to Reach USD 67.8 Billion by 2030, Growing at 4.80% CAGR

Ameco Research is proud to announce the launch of its latest market research report, Thermoform Packaging Market. This comprehensive report provides in-depth analysis and insights into the current market trends and future projections in the Industry/Market Segment. Ameco Research has been at the forefront of providing quality market research…

Thermoform Packaging Market 2022 | Detailed Report

According to Market Study Report, Thermoform Packaging Market provides a comprehensive analysis of the Thermoform Packaging Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Download FREE Sample Report @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5384435

The report provides a comprehensive analysis of company profiles listed below:

- WestRock Company

- Amcor Limited

- Tray Pack…

Thermoform Packaging Market: Food Industry to be Key Consumer of Thermoform Pack …

Global thermoform packaging market is divided into blister, clamshell, skin, and others. Of these, the blister packaging is expected to witness a remarkable growth rate during the forecast period. The growth of this segment will be due to the rising usage of this packaging type in the pharmaceutical industry as it is known to prevent product contamination. Blister packaging is also being used for packaging certain food products. Thermoform packaging…