Press release

Medical Device Packaging Market Size, Growth, Trends and Key Developments

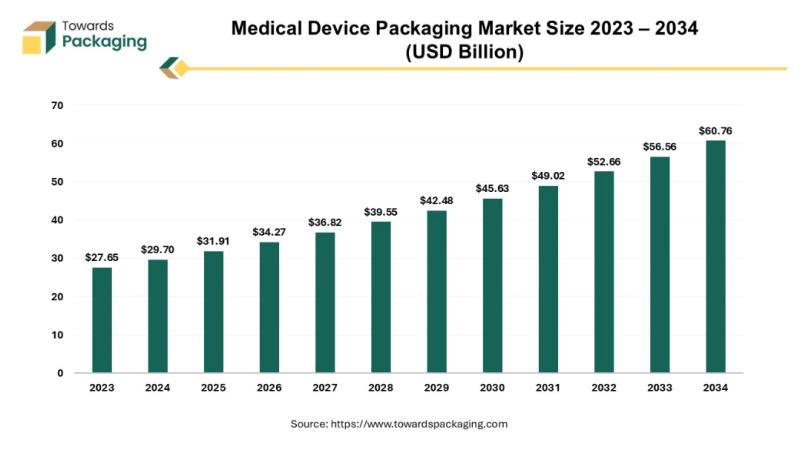

The global medical device packaging market is experiencing substantial growth, reflecting its crucial role in ensuring the safe and effective delivery of medical products across the world. In 2024, the market size is estimated to be valued at USD 29.70 billion, with expectations to reach USD 60.76 billion by 2034. This growth trajectory suggests an impressive compound annual growth rate (CAGR) of 7.42% from 2024 to 2034.Download Statistical Data: https://www.towardspackaging.com/download-statistics/5149

Market Overview and Growth Projections

The medical device packaging industry is integral to the healthcare sector, ensuring that medical devices are securely transported, stored, and used. Starting at a value of USD 24.87 billion in 2022, the sector is poised to expand, with a forecasted market value of USD 52.67 billion by 2032. This growth is a testament to the increasing demand for medical devices and the critical role packaging plays in preserving the sterility and functionality of these devices.

The expansion of the medical device packaging market is driven by various factors, including the rapid advancement in healthcare technologies, the growing emphasis on patient safety, and the rising demand for packaged medical products worldwide. As more medical devices are introduced into the market, the need for specialized packaging solutions grows, paving the way for significant market developments in the coming years.

Key Regional Insights: North America and Asia-Pacific Lead the Way

North America has long been the central hub for the medical device packaging industry. The region's advanced healthcare infrastructure, coupled with its stringent regulatory requirements for medical packaging, has made it a prime location for the development and distribution of packaged medical devices. The United States, in particular, plays a dominant role in driving the market forward, thanks to its robust healthcare system and the increasing adoption of innovative medical technologies.

Meanwhile, the Asia-Pacific region is emerging as a key growth area for medical device packaging. The region's expanding healthcare sector, growing manufacturing capabilities, and increasing healthcare expenditure are contributing to the surging demand for medical device packaging solutions. As more medical devices are manufactured and distributed across Asia-Pacific countries, the region is poised to become a significant player in the global medical device packaging market.

The Role of Packaging in Medical Devices

Medical device packaging is far more than just a protective container for devices. It encompasses a comprehensive set of materials, processes, and technologies designed to ensure the integrity and safety of medical products throughout their lifecycle. Packaging is vital for preserving sterility, protecting devices from contamination, and ensuring that they function as intended once they reach healthcare professionals and patients.

One of the most significant aspects of medical device packaging is the use of plastic materials. Plastics have become a go-to material for packaging due to their versatility, durability, and cost-effectiveness. They play a pivotal role in ensuring the security and protection of medical devices during transportation and storage. Additionally, the need for sterile packaging solutions has led to the widespread adoption of advanced technologies, such as sterilization and tamper-evident packaging, to guarantee that medical devices arrive at their destination free from contamination.

Among the various types of packaging solutions, pouches stand out for their ability to offer precise protection to medical devices. These pouches are designed to shield devices from external elements, such as moisture, dust, and harmful pathogens, while maintaining their sterility. The growing demand for pouches is a direct response to the increasing need for sterile, ready-to-use medical products in environments like operating rooms, emergency rooms, and other critical healthcare settings.

Importance of Labels and Distribution Channels

The role of labels in the medical device sector cannot be overstated. Labels provide essential information about the device, including its specifications, usage instructions, and expiration dates, which are crucial for ensuring patient safety and proper device use. As regulatory frameworks become stricter, the importance of accurate and clear labeling is rising, ensuring compliance with standards and improving patient outcomes.

In terms of distribution, direct channels have become an essential part of the medical device packaging market. Direct distribution allows manufacturers to streamline their supply chains, ensuring faster delivery times and reduced costs. It also allows for closer relationships between manufacturers, healthcare providers, and end users, leading to improved product quality and greater customer satisfaction.

Medical Packaging's Role in Diagnostics and Monitoring Equipment

Packaging plays an especially critical role in the safe transport and storage of monitoring and diagnostic equipment. These devices are often fragile and sensitive to environmental factors, requiring robust packaging solutions that preserve their functionality and safety. Effective packaging ensures that diagnostic tools and monitoring devices reach healthcare facilities in optimal condition, allowing for accurate and timely patient care.

Emerging Trends in the Medical Device Packaging Market: Innovation, Sustainability, and Safety

The medical device packaging industry is undergoing a transformation, driven by evolving technological advancements, environmental concerns, and the growing complexity of medical devices. As the healthcare sector continues to expand and diversify, medical device packaging is becoming an increasingly vital component in ensuring patient safety, improving supply chain efficiency, and meeting regulatory standards. Below, we explore some of the key trends shaping the future of medical device packaging.

Eco-friendly and Sustainable Packaging: A Growing Imperative

Environmental sustainability has taken center stage in industries across the globe, and the medical device packaging sector is no exception. As concerns over plastic waste, pollution, and environmental degradation continue to rise, manufacturers are being pressured to adopt more eco-friendly packaging solutions.

One of the most significant shifts in the industry is the reduction of plastic usage. Manufacturers are exploring biodegradable materials, recyclable packaging, and even reusable packaging options to minimize environmental impact. While the transition to greener materials is gaining momentum, it remains a balancing act between sustainability goals and the need to maintain the integrity, sterility, and safety of medical devices.

Governments and regulatory bodies are playing a critical role in pushing for more sustainable practices, often mandating packaging waste reduction and encouraging the use of eco-friendly materials. These regulations are driving innovations in packaging design that align with environmental sustainability goals without compromising the safety and sterility of medical products.

IoT Integration and the Rise of Smart Packaging

The integration of Internet of Things (IoT) technology is revolutionizing the way medical devices are tracked, monitored, and protected during transport and storage. One of the most exciting developments in medical device packaging is the rise of smart packaging, equipped with Radio Frequency Identification (RFID) or Near Field Communication (NFC) technology. These smart solutions enable better tracking and traceability of devices from manufacturer to end user, ensuring compliance with regulatory requirements while enhancing supply chain visibility.

By incorporating IoT technology into packaging, manufacturers can monitor environmental conditions, such as temperature and humidity, during shipping and storage. This capability is particularly valuable for sensitive products like biologics, vaccines, and diagnostic devices, which must be kept under strict environmental conditions to preserve their efficacy.

The ability to monitor these conditions remotely provides valuable data that not only helps ensure the integrity of medical devices but also allows manufacturers and healthcare providers to take proactive measures to prevent damage or spoilage.

Sterilization and Infection Control: The Vital Role of Packaging

Sterilization is a critical component in the safety and efficacy of medical devices, and packaging plays a central role in maintaining sterility until the device is ready for use. As medical devices become more complex and specialized, the packaging solutions used to safeguard these products are evolving to meet increasingly stringent standards.

Recent innovations in sterilization techniques, such as hydrogen peroxide vapor, ethylene oxide, and gamma radiation, are influencing the design and development of medical device packaging. These techniques ensure that devices remain sterile throughout their lifecycle, from production to final use.

Moreover, the demand for tamper-evident packaging is growing, particularly for high-risk medical devices. Tamper-evident packaging provides clear visual indicators that a package has not been opened or altered, adding an extra layer of security and ensuring that the device reaches its destination safely and uncompromised.

Customization and User-Friendly Designs: Meeting Patient Needs

As the healthcare industry shifts toward more personalized treatment options, the packaging of medical devices is also undergoing a transformation. There is a growing emphasis on creating user-friendly designs that enhance patient safety and usability, particularly in home healthcare settings.

Medical devices used at home, such as diabetes management kits, respiratory equipment, and wound care products, require packaging that is easy to open, intuitive to use, and clearly labeled. Clear instructions and packaging that minimize the risk of errors are essential to ensuring patients can use these devices correctly and safely.

Moreover, as medical devices become more complex, packaging is being customized to meet the specific needs of the device. Anti-static packaging, for example, is being used for electronic medical devices to prevent damage from static electricity. Additionally, custom-molded packaging is designed to prevent mechanical damage during transport, providing optimal protection for delicate or sensitive equipment.

Automation and Supply Chain Optimization: Enhancing Efficiency

As the demand for medical devices continues to grow, manufacturers are increasingly turning to automation to streamline production and packaging processes. Automated packaging lines are gaining popularity for their ability to improve efficiency, reduce human error, and enhance scalability, especially in the production of medical devices in large volumes.

Packaging plays a crucial role in optimizing the entire supply chain. Innovations that reduce packaging volume, improve durability, and facilitate easier transport can help manufacturers reduce costs and enhance operational efficiency. For instance, collapsible or stackable packaging designs help reduce storage space, while durable packaging materials ensure that devices are protected during long shipments.

Security and Anti-Counterfeiting: Protecting Patients and Brands

As counterfeit products continue to pose a significant threat to patient safety and brand integrity, the medical device packaging market is evolving to include advanced security features that help protect against fraud. Technologies such as holograms, barcodes, and tamper-evident seals are now commonly integrated into packaging to ensure the authenticity of medical devices.

Serialization requirements in regions such as the U.S. and Europe have further fueled this trend. By tracking and tracing medical devices through the supply chain, serialization helps prevent counterfeit devices from entering the market, safeguarding both patients and healthcare professionals from potential harm.

Packaging for Home Healthcare: Convenience and Safety

The rise of home healthcare has created a demand for packaging that is not only safe and secure but also convenient and easy for patients and healthcare providers to use. Packaging designed for home use must be intuitive, user-friendly, and facilitate safe storage, handling, and disposal of medical devices.

For patients, packaging must be designed with simplicity in mind. Devices should be easy to open, with clear labeling and instructions that ensure correct usage. For healthcare providers, packaging must ensure that devices are delivered in a sterile and intact condition, ready for immediate use in the home setting.

Recent Developments in the Medical Device Packaging Market: Webblogic's Groundbreaking Innovations

The medical device packaging industry continues to evolve as technological advancements, regulatory pressures, and the increasing demand for patient safety drive the market. A significant development that is poised to make waves in the sector comes from Webblogic, a renowned leader in medical device manufacturing technology. In May 2024, Webblogic announced the upcoming launch of its cutting-edge manufacturing and packaging equipment tailored specifically for the pharmaceutical, life sciences, and medical device industries.

Webblogic's Pioneering Role in Medical Device Packaging

Webblogic has long been at the forefront of innovation within the manufacturing sector, and its latest initiative underscores its commitment to advancing the medical device packaging market. The company plans to introduce a suite of innovative production and packaging tools designed to meet the evolving needs of the life science and medical device sectors.

What sets Webblogic's new offering apart is its integrated approach to both manufacturing and packaging. The company does not simply provide standalone equipment but offers a comprehensive range of services that extend beyond the hardware itself. This includes technology licensing, design, development, and commercialization-all crucial components for companies in the medical device space looking to streamline their operations while maintaining high standards of quality and compliance.

A Holistic Approach to Innovation

The significance of Webblogic's new technology is not just in the machines and equipment it plans to introduce but also in the holistic services that accompany it. By offering a complete suite of solutions, Webblogic is positioning itself as more than just a supplier of packaging equipment. Their approach addresses the entire lifecycle of medical device packaging, from initial design and development through to commercialization, allowing manufacturers to adopt a seamless process that reduces costs, enhances efficiency, and ensures compliance with stringent industry regulations.

The company's focus on technology licensing is particularly noteworthy. It allows medical device manufacturers to access cutting-edge technologies that would otherwise be out of reach, enabling them to stay competitive in an increasingly demanding market. Through licensing agreements, Webblogic facilitates faster adoption of new innovations, helping medical device companies stay ahead of the curve while improving the safety and efficacy of their packaging solutions.

Enhancing Efficiency in the Life Sciences and Medical Device Sectors

One of the key drivers behind Webblogic's upcoming release is the ongoing demand for more efficient, cost-effective, and reliable packaging solutions in the life sciences and medical device sectors. As the healthcare industry continues to grow, the need for packaging solutions that ensure the safe and secure transport of sensitive products is paramount. Webblogic's state-of-the-art equipment will help meet these demands, offering manufacturers the tools needed to maintain high standards of sterility, durability, and compliance.

Moreover, the integration of Webblogic's advanced manufacturing and packaging equipment into the medical device supply chain promises to streamline processes, reduce human error, and improve overall productivity. The result is not just better packaging solutions but also enhanced operational efficiency across the entire production line, which is crucial for manufacturers aiming to meet growing demand while minimizing waste and costs.

A Step Forward in Meeting Industry Challenges

As regulatory requirements surrounding medical device packaging become more stringent, Webblogic's comprehensive approach ensures that manufacturers can navigate these challenges effectively. The company's innovations will enable manufacturers to stay compliant with evolving standards, particularly in areas like sterilization, tracking, and safety. With an increased emphasis on sustainability, Webblogic's solutions are also expected to help companies align with the growing demand for eco-friendly packaging, making it easier to adopt sustainable practices without compromising the safety and integrity of the products.

In addition, the rise of smart packaging and the need for enhanced traceability are pushing the industry toward more technologically advanced solutions. Webblogic's offerings are poised to integrate seamlessly with these trends, incorporating RFID, NFC, and IoT capabilities to improve the tracking and monitoring of medical devices throughout the supply chain. By leveraging these technologies, manufacturers can ensure that their devices are transported under the correct conditions, reducing the risk of spoilage, damage, or contamination.

Source: https://www.towardspackaging.com/insights/medical-device-packaging-market-sizing

Baner

Buy Premium Global Insight: https://www.towardspackaging.com/price/5149

Review the Full TOC for the Medical Device Packaging Market Report: https://www.towardspackaging.com/table-of-content/medical-device-packaging-market-sizing

Get the latest insights on packaging industry segmentation with our Annual Membership - https://www.towardspackaging.com/get-an-annual-membership

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

Towards Healthcare: https://www.towardshealthcare.com

Towards Automotive: https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Medical Device Packaging Market Size, Growth, Trends and Key Developments here

News-ID: 3809993 • Views: …

More Releases from Towards Packaging

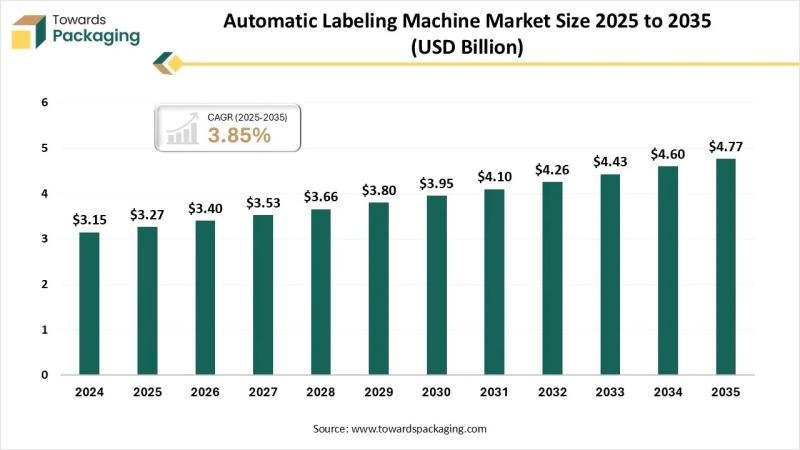

Automatic Labeling Machine Market Set for Strong Growth Through 2035

The global automatic labeling machine market is poised for steady expansion, rising from USD 3.4 billion in 2026 to USD 4.77 billion by 2035 at a CAGR of 3.85%. Demand is being driven by rapid automation in packaging lines, stringent labeling regulations, and the shift toward high-speed, error-free production across industries.

Download Sample: https://www.towardspackaging.com/download-sample/5882

Self-adhesive labeling systems currently hold the largest share at 39%, supported by their versatility and cost efficiency. Meanwhile,…

Unleashing Growth in the Liquid Packaging Market with Strategic Innovations

The liquid packaging industry is experiencing remarkable growth, with projections indicating an increase from USD 397.36 billion in 2025 to USD 645.43 billion by 2034. This growth, at a compound annual growth rate (CAGR) of 5.7%, signifies the expanding demand for liquid packaging solutions across a variety of sectors. As we delve into the market dynamics, it becomes clear that the liquid packaging sector is evolving rapidly, with several key…

Advancements in Hot-Fill Food Packaging Paving the Way for a Sustainable Future

The global hot-fill food packaging market is experiencing a steady rise, with an expected market value of USD 71.26 billion by 2033, up from USD 49.85 billion in 2023. This growth is projected to follow a compound annual growth rate (CAGR) of 3.76% from 2024 to 2033, reflecting the increasing demand for innovative packaging solutions in the food and beverage sector.

Download a Brochure of Hot-fill Food Packaging Market: https://www.towardspackaging.com/download-brochure/5266

Hot-Fill…

Driving Growth and Innovation in the Plastic Bag Market

The plastic bag market is undergoing significant growth, with its value reaching an estimated US$ 25.10 billion in 2023. Projections suggest that this market could hit a substantial US$ 35.41 billion by 2033, marking a steady compound annual growth rate (CAGR) of 3.5% from 2024 to 2034. This growth is largely driven by the expanding needs of various industries for efficient and cost-effective packaging solutions.

Download a Brochure of Plastic Bag…

More Releases for Webblogic

Medical Device Packaging Market Analysis, Key Segments and Trends

The medical device packaging market has emerged as a cornerstone of the healthcare industry, ensuring the safety, sterility, and functionality of medical equipment throughout its lifecycle. Valued at USD 29.70 billion in 2024, the global medical device packaging market is set to more than double, reaching an impressive USD 60.76 billion by 2034. This remarkable growth trajectory, driven by a compound annual growth rate (CAGR) of 7.42% from 2024 to…