Press release

Industrial Packaging Market Size, Trends and Regional Growth

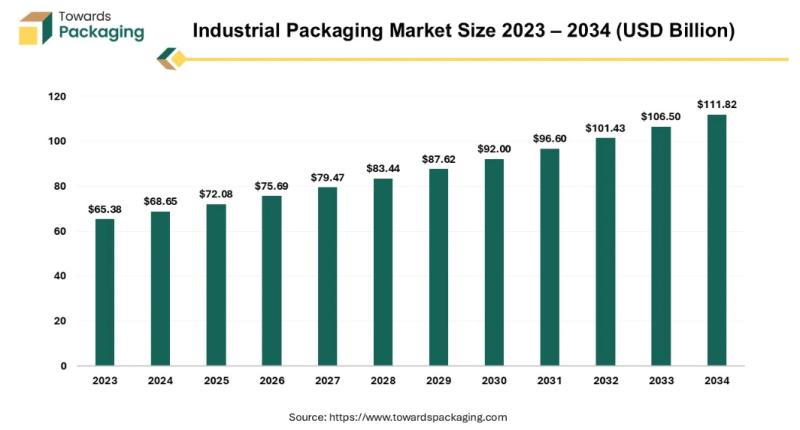

The industrial packaging market is on a remarkable trajectory, with a projected valuation of USD 65.38 billion in 2023 and an estimated growth to USD 111.82 billion by 2034. This growth represents a robust compound annual growth rate (CAGR) of 5% from 2024 to 2034. Several driving factors, including the emergence of sustainability trends and rapid technological advancements, are propelling this market's expansion.Download Statistical Data: https://www.towardspackaging.com/download-statistics/5152

A Snapshot of Industrial Packaging Market Growth

The global industrial packaging sector has witnessed significant growth, starting with a value of USD 62.56 billion in 2022. By 2032, it is expected to surge to an estimated USD 101.42 billion. This expansion, fueled by a CAGR of 5.0%, is indicative of the increasing demand for efficient, secure, and environmentally friendly packaging solutions across industries.

Industrial packaging plays a crucial role in modern supply chains, offering safety, efficiency, and cost savings. It ensures that products and goods are transported securely from point A to point B, mitigating risks such as damage or spoilage. This functionality is especially vital for manufacturers, distributors, wholesalers, e-commerce platforms, and retail businesses that rely on industrial packaging to safeguard their products during transit.

Technological Advancements and Sustainability Trends

One of the key drivers behind the growth of the industrial packaging market is the increasing focus on sustainability and technological innovation. As industries shift toward eco-friendly solutions, packaging solutions are evolving to meet these demands. Manufacturers are continuously adopting advanced materials, including recyclable, biodegradable, and reusable options, which are in high demand across various sectors.

Additionally, technological advancements in packaging design, automation, and materials have significantly improved the speed and safety of product transit. The development of advanced machinery and packaging solutions has allowed companies to reduce costs, minimize waste, and enhance the overall efficiency of the supply chain.

Regional Growth and the Vital Role of Industrial Packaging

Asia-Pacific: The Growth Epicenter

The Asia-Pacific region has been a major contributor to the expansion of the industrial packaging market. With its booming manufacturing sector and growing demand for packaged goods, this region is poised for significant growth. Advances in technology, coupled with the increasing adoption of sustainable practices, are driving the demand for industrial packaging solutions. Countries like China, India, and Japan are at the forefront of this change, leading the charge in both production and consumption of industrial packaging.

North America: A Dominant Force

In North America, the industrial packaging market is thriving, largely due to the advanced technological capabilities and the demand for high-quality packaging in sectors such as automotive, chemicals, and consumer goods. North America's commitment to sustainability is also reshaping the landscape, with increased adoption of eco-friendly materials and smart packaging technologies that enhance product protection and reduce environmental impact.

Plastic Innovations: A Dominating Force

Plastic has long been a dominant material in industrial packaging due to its versatility and protective qualities. However, with growing concerns over environmental sustainability, there has been a shift toward developing innovative plastic alternatives and recyclable materials. This evolution is helping companies reduce their carbon footprint while maintaining the efficiency and safety of packaging solutions.

The Role of Intermediate Bulk Containers

Intermediate bulk containers (IBCs) have become increasingly popular in the industrial packaging market, particularly for the storage and transportation of chemicals, liquids, and granular materials. Their ability to hold large quantities and offer better protection against leaks and contamination has made them an invaluable asset in various industries. The rising demand for IBCs is a testament to the ongoing advancements in industrial storage solutions.

The Growing Importance of Industrial Packaging in Global Supply Chains

In today's fast-paced global economy, industrial packaging has become an indispensable element of supply chain management. By facilitating faster and more secure transportation, industrial packaging helps businesses meet the increasing demand for on-time delivery and improved product safety.

For example, the ability to streamline the distribution process through packaging that protects products during transit has resulted in reduced manufacturing cycles and enhanced shipping efficiency. Moreover, industrial packaging solutions have allowed businesses to shift toward a just-in-time inventory model, reducing the need for large storage spaces and minimizing inventory holding costs.

Cost-Efficiency and Sustainability: A Winning Combination

Industrial packaging's growing importance also lies in its ability to deliver significant cost savings. Through enhanced packaging design, companies can reduce damage during transit, leading to lower return rates and fewer product losses. Furthermore, manufacturers and merchants can now move products more efficiently and at a faster pace, which has a positive impact on their bottom line.

Another significant benefit of industrial packaging is its role in inventory management. The shift to daily purchasing rather than relying on bulk orders has resulted in reduced inventory holding costs. This model helps businesses save money by minimizing the amount of goods held in storage while ensuring that products are delivered promptly.

The Future of Industrial Packaging: Innovations and Acquisitions

As the industrial packaging market continues to expand, key players in the sector are investing in acquisitions and partnerships to strengthen their market positions. A notable example is the recent acquisition of Pakella by Antalis, a global leader in paper and industrial packaging. This move highlights the growing trend of consolidation within the industry as companies look to expand their capabilities and product offerings to meet rising demand.

The future of industrial packaging is poised for continued growth, driven by technological advancements, sustainability initiatives, and an increasing focus on cost-efficiency. As industries around the world rely more on efficient packaging solutions, the industrial packaging market will continue to evolve to meet these demands.

AI Integration Driving Innovation in the Industrial Packaging Market

The industrial packaging sector, a cornerstone of the global supply chain, is undergoing a transformative shift with the integration of Artificial Intelligence (AI). As industries continue to evolve, the demand for smarter, more efficient solutions grows. AI technologies, particularly machine learning and computer vision, are making waves by revolutionizing industrial packaging processes. This integration is not just about automation; it's about elevating the entire value chain-driving operational efficiency, product innovation, and supply chain management to unprecedented heights.

AI-Powered Automation: Revolutionizing Production Efficiency

One of the most significant impacts AI has made in the industrial packaging market is through automation. Packaging lines that once relied heavily on manual labor and human oversight are now leveraging AI-powered systems to streamline operations. These intelligent systems are capable of making real-time adjustments to packaging parameters, ensuring consistent quality and reducing the possibility of errors. With machine learning algorithms, these systems can even identify patterns in production data, leading to optimized processes that minimize waste and improve overall performance.

AI-driven automation is enabling packaging plants to operate more efficiently, increasing output while reducing the need for manual intervention. This has resulted in not only faster production times but also a marked decrease in labor costs. As a result, manufacturers are finding it more cost-effective to ramp up production while maintaining the highest standards of packaging quality.

Predictive Maintenance: Proactive Management of Equipment Health

Beyond improving production efficiency, AI is also playing a pivotal role in predictive maintenance. Traditional maintenance strategies often relied on scheduled inspections or reactive repairs, which could lead to unplanned downtime and expensive repairs. With the advent of AI, companies can now predict when equipment is likely to fail based on real-time data collected from sensors and historical performance.

Through machine learning algorithms, AI systems can analyze vast amounts of operational data to identify early warning signs of mechanical issues or wear and tear. This proactive approach allows businesses to address potential problems before they escalate, leading to fewer disruptions in the production process and a reduction in costly repairs. Predictive maintenance not only minimizes downtime but also optimizes the lifespan of packaging equipment, further driving cost savings and enhancing overall productivity.

AI in Supply Chain Optimization: Smarter, More Efficient Logistics

AI is also revolutionizing supply chain management in the industrial packaging market. With the ability to process and analyze large datasets, AI-powered systems can predict demand patterns, optimize inventory levels, and streamline logistics processes. This predictive analytics capability enables businesses to forecast customer needs more accurately, ensuring that packaging materials are always available when needed without overstocking or understocking.

AI-driven supply chain optimization leads to more efficient logistics, which in turn reduces lead times and shipping costs. By leveraging AI to track products in real-time, companies can offer better visibility throughout the supply chain, improving transparency and reducing the likelihood of delays. The end result is faster delivery times, lower operating costs, and ultimately, enhanced customer satisfaction.

AI's Role in Enhancing Product Innovation

Innovation is at the heart of AI's influence on the industrial packaging market. With the ability to analyze vast amounts of data from various sources-ranging from customer feedback to market trends-AI systems are enabling packaging manufacturers to create more innovative, sustainable, and efficient packaging solutions. AI algorithms can identify emerging trends and consumer preferences, allowing businesses to adapt quickly and introduce new products that meet the evolving needs of the market.

Furthermore, AI is playing a significant role in developing smart packaging solutions. These intelligent packaging systems can monitor the condition of the contents, detect tampering, and even provide real-time tracking and data to consumers. As more industries adopt such smart packaging technologies, AI will continue to drive innovation in the market, creating new possibilities for packaging manufacturers and their customers.

Environmental Impact: AI's Role in Sustainable Packaging Solutions

Sustainability is a growing concern for many industries, and the industrial packaging sector is no exception. As businesses face increasing pressure to reduce their environmental footprint, AI is stepping in to help. By optimizing packaging designs and processes, AI can help companies reduce material waste, energy consumption, and emissions. Machine learning algorithms can analyze the environmental impact of various packaging materials and recommend more sustainable alternatives without compromising on functionality or cost.

AI can also assist in the recycling process. Through computer vision and data analysis, AI-powered systems can sort and identify recyclable materials more accurately, improving the efficiency of recycling operations. This contributes to the growing trend of circular economy practices, where packaging materials are reused or repurposed rather than disposed of, further supporting environmental sustainability in the packaging industry.

Source: https://www.towardspackaging.com/insights/industrial-packaging-market-sizing

Baner

Buy Premium Global Insight: https://www.towardspackaging.com/price/5152

Review the Full TOC for the Industrial Packaging Market Report: https://www.towardspackaging.com/table-of-content/industrial-packaging-market-sizing

Get the latest insights on packaging industry segmentation with our Annual Membership - https://www.towardspackaging.com/get-an-annual-membership

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

Towards Healthcare: https://www.towardshealthcare.com

Towards Automotive: https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Packaging Market Size, Trends and Regional Growth here

News-ID: 3808465 • Views: …

More Releases from Towards Packaging

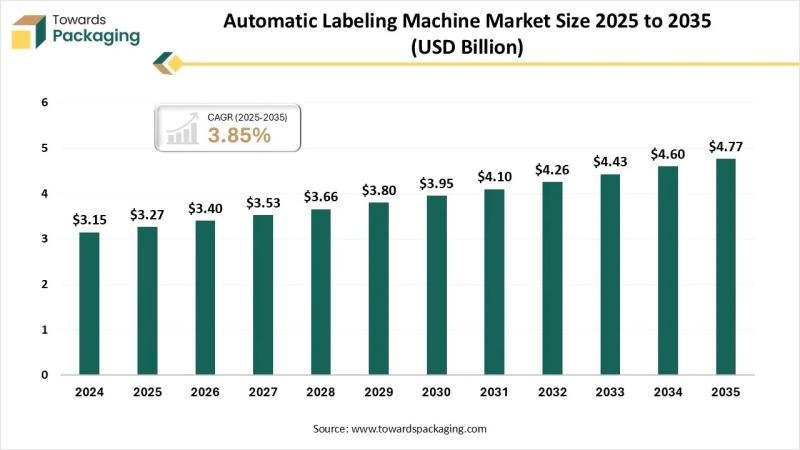

Automatic Labeling Machine Market Set for Strong Growth Through 2035

The global automatic labeling machine market is poised for steady expansion, rising from USD 3.4 billion in 2026 to USD 4.77 billion by 2035 at a CAGR of 3.85%. Demand is being driven by rapid automation in packaging lines, stringent labeling regulations, and the shift toward high-speed, error-free production across industries.

Download Sample: https://www.towardspackaging.com/download-sample/5882

Self-adhesive labeling systems currently hold the largest share at 39%, supported by their versatility and cost efficiency. Meanwhile,…

Unleashing Growth in the Liquid Packaging Market with Strategic Innovations

The liquid packaging industry is experiencing remarkable growth, with projections indicating an increase from USD 397.36 billion in 2025 to USD 645.43 billion by 2034. This growth, at a compound annual growth rate (CAGR) of 5.7%, signifies the expanding demand for liquid packaging solutions across a variety of sectors. As we delve into the market dynamics, it becomes clear that the liquid packaging sector is evolving rapidly, with several key…

Advancements in Hot-Fill Food Packaging Paving the Way for a Sustainable Future

The global hot-fill food packaging market is experiencing a steady rise, with an expected market value of USD 71.26 billion by 2033, up from USD 49.85 billion in 2023. This growth is projected to follow a compound annual growth rate (CAGR) of 3.76% from 2024 to 2033, reflecting the increasing demand for innovative packaging solutions in the food and beverage sector.

Download a Brochure of Hot-fill Food Packaging Market: https://www.towardspackaging.com/download-brochure/5266

Hot-Fill…

Driving Growth and Innovation in the Plastic Bag Market

The plastic bag market is undergoing significant growth, with its value reaching an estimated US$ 25.10 billion in 2023. Projections suggest that this market could hit a substantial US$ 35.41 billion by 2033, marking a steady compound annual growth rate (CAGR) of 3.5% from 2024 to 2034. This growth is largely driven by the expanding needs of various industries for efficient and cost-effective packaging solutions.

Download a Brochure of Plastic Bag…

More Releases for Industrial

Industrial Display Market: Technology Advancements Driving Industrial Visualizat …

In recent years, the global Industrial Display Market has transformed significantly, driven by evolving consumer preferences, rapid technological advancements, and an increasing focus on sustainability. Our comprehensive Industrial Display Market Research Report is your essential guide to navigate this dynamic landscape, offering actionable insights into emerging trends, growth drivers, and key opportunities for your business.

Unlock in-depth analyses of the competitive supplier landscape, demand dynamics, and market projections with…

Industrial Display Market: Technology Advancements Driving Industrial Visualizat …

In recent years, the global Industrial Display Market has transformed significantly, driven by evolving consumer preferences, rapid technological advancements, and an increasing focus on sustainability. Our comprehensive Industrial Display Market Research Report is your essential guide to navigate this dynamic landscape, offering actionable insights into emerging trends, growth drivers, and key opportunities for your business.

Unlock in-depth analyses of the competitive supplier landscape, demand dynamics, and market projections with…

Industrial Auction Services Market Auctioning Industrial Assets By 2030 | Heath …

The Report on "Industrial Auction Services Market" provides Key Benefits, Market Overview, Regional Analysis, Market Segmentation, Future Trends Upto 2030 by Infinitybusinessinsights.com. The report will assist reader with better understanding and decision making.

The industrial auction services market is a diverse and dynamic sector that encompasses a wide range of industries, including manufacturing, construction, automotive, and more. These services are utilized by companies looking to optimize their asset management, streamline operations,…

RDM Industrial Products - Laboratory and Industrial Furniture Supplier

RDM Industrial Products Inc. is one of the most reputed and leading laboratory and industrial furniture solutions supplier and manufacturer. The company was established in 1977 and has been serving their growing clientele proudly for over 40 years. Their quality products cater to industries including healthcare, electronics, biotechnology, laboratory, industrial and more. The company is based out of California and their shipments are done all across the globe. QUALITY-SERVICE-TIMING are…

Industrial Fasteners Market # industrial fasteners and supply # industrial faste …

An insightful study, titled “Global Industrial Fasteners Market” has been freshly broadcasted to the vast research repository of Market Research Reports Search Engine (MRRSE). The research study provides detailed comprehensions and forecasts future growth of the global market with an in-depth study of the factors impacting revenue growth throughout the mentioned forecast period. Further, a deep analysis on the major players from diverse regions is also present in the report.

Get…

Global Industrial PC Market To Reach Us$8,784.2 Mn By 2025: By Type - Panel Indu …

Researchmoz added Most up-to-date research on "Global Industrial PC Market To Reach Us$8,784.2 Mn By 2025: By Type - Panel Industrial PC, Box Industrial PC And Embedded Industrial PC" to its huge collection of research reports.

Industrial PC is a ruggedized system designed to perform computing applications for various industries. Industrial PC is a PC-based computing podium mainly used for data acquisition or process control, and in some cases, it is…