Press release

Detailed Explanation of the Characteristics, Processing Techniques and Applications of PE and PP Materials

1.Material OverviewPE, PP, PVC, PS, PC, PF, EP, ABS, PA, PMMA, etc. are collectively referred to as plastic materials, also known as polymer materials. They are a type of synthetic materials with plasticity made from high-molecular compounds through various processing methods. Plastic materials have the advantages of being lightweight, having high strength, good corrosion resistance, and excellent insulation. They are widely used in packaging, construction, automobiles, electronics, and many other fields.

Polyethylene (PE): It is a lightweight, flexible thermoplastic with good chemical resistance. Depending on density, it can be classified into high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

Polypropylene (PP): It has high heat resistance, chemical resistance and rigidity, and is commonly used in automotive parts and household appliances.

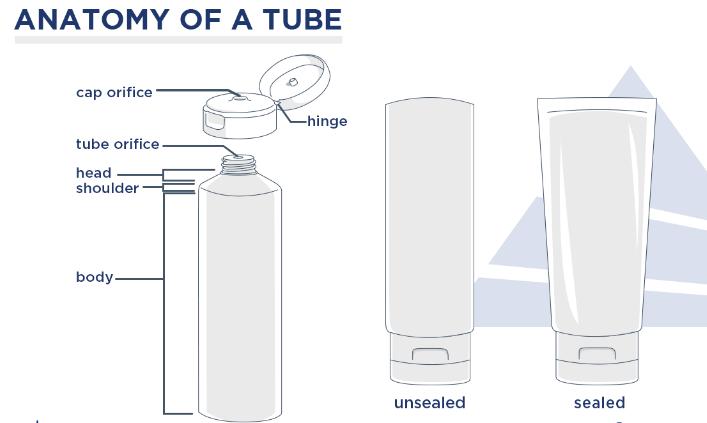

Image: https://ecdn6.globalso.com/upload/p/494/image_product/2024-12/anatomy-or-a-tube.png

Image: https://ecdn6.globalso.com/upload/p/494/image_product/2024-12/tube-head-style.png

2. Polyethylene (PE)

Physical and Chemical Properties: Polyethylene (PE) is a linear high-molecular polymer with an extremely simple molecular structure, composed of repeating "-CH2-CH2-" units. This structure endows PE with a variety of unique physical and chemical properties.

Lightweight: PE has a low density, approximately between 0.91 and 0.96 g/cm, making it a representative of lightweight materials.

Chemical Resistance: PE shows good chemical stability towards most acids, bases, and salt solutions.

Electrical Insulation: As a non-polar material, PE has excellent electrical insulation performance.

Low Temperature Resistance: PE can maintain its physical properties at temperatures as low as -70 degrees C. PE can be reshaped after heating, facilitating recycling and reprocessing.

Processing Methods: The processing methods of polyethylene are diverse and mainly include the following.

Extrusion: used for producing pipes, insulation layers of wires and cables, etc.

Injection Molding: suitable for manufacturing small containers, toys, etc.

Blow Molding: used for producing hollow bottles and containers.

Compression Molding: suitable for manufacturing larger plastic components, used for manufacturing thin-walled packaging materials and trays.

Application Fields: Polyethylene has a wide range of application fields. Here are some main application examples.

Packaging Materials: PE films are widely used in food packaging and commodity packaging due to their light weight and good protective performance.

Plastic Pipes: HDPE pipes are often used for water and gas transportation due to their chemical resistance and wear resistance.

Wires and Cables: PE is widely used as an insulating material in the manufacturing of wires and cables.

Agriculture: PE is used to manufacture agricultural films, such as for soil covering technology.

Medical Field: Due to its bio-compatibility and chemical resistance, PE is also used in the manufacturing of certain medical devices.

Automotive Industry: PE is used in the manufacturing of automotive parts, such as fuel tanks and bumpers, due to its light weight and impact resistance.

Image: https://ecdn6.globalso.com/upload/p/494/image_product/2024-12/pe-and-pp-materials.png

3.Polypropylene (PP) Physical and Chemical Properties

Polypropylene (PP) is a linear thermoplastic polymer made from the polymerization of propylene monomers. PP has the following notable physical and chemical properties

Heat Resistance: The melting point of PP is between 160 and 170 degrees C, making it heat-resistant and suitable for products that need to withstand high temperatures.

Chemical Resistance: PP is stable against water, inorganic salts, acids, and bases but is susceptible to certain organic solvents.

Rigidity: PP has high rigidity, allowing it to maintain its shape under heavy loads.

Fatigue Resistance: PP has good fatigue resistance and is suitable for applications that require repeated bending or twisting. PP can be repeatedly heated and cooled without losing its physical properties, making it easy to recycle.

Processing Methods: Polypropylene can be processed into various products through multiple techniques.

Extrusion: Used for manufacturing PP pipes, sheets, rods, etc.

Injection Molding: Suitable for producing small to medium-sized plastic products such as containers, lids, and automotive parts.

Blow Molding: Used for making large hollow plastic products like bottles and buckets. Used for creating thin-walled plastic packaging containers or trays.

Fiber Manufacturing: PP can also be made into fibers through stretching and weaving processes for ropes, carpets, etc.

Application Areas: Polypropylene has a wide range of applications, including the following examples.

Automotive Industry: PP is widely used in the automotive industry for both interior and exterior parts due to its light weight and heat resistance, such as instrument panels and bumpers.

Textile Industry: PP fibers are used in the production of ropes, carpets, and clothing.

Packaging Materials: Due to its light weight and chemical resistance, PP is commonly used in packaging materials for both food and non-food items.

Household Appliances: PP is used in the manufacture of microwave-safe containers, refrigerator drawers, and other household appliance components.

Construction Industry: PP pipes [https://www.cosmetictubefactory.com/]and sheets are used in building piping systems and decorative materials.

Medical Field: Due to its bio-compatibility, PP is also used in the production of some disposable medical supplies, such as syringes and test tubes.

Media Contact

Company Name: YANGZHOU RUNFANG PLASTIC PACKAGING MATERIAL CO., LTD.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=detailed-explanation-of-the-characteristics-processing-techniques-and-applications-of-pe-and-pp-materials]

Country: China

Website: https://www.cosmetictubefactory.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Detailed Explanation of the Characteristics, Processing Techniques and Applications of PE and PP Materials here

News-ID: 3806656 • Views: …

More Releases from ABNewswire

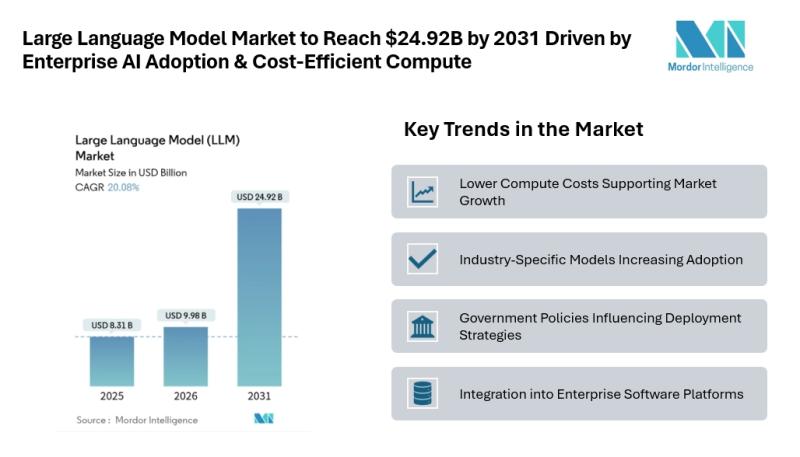

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

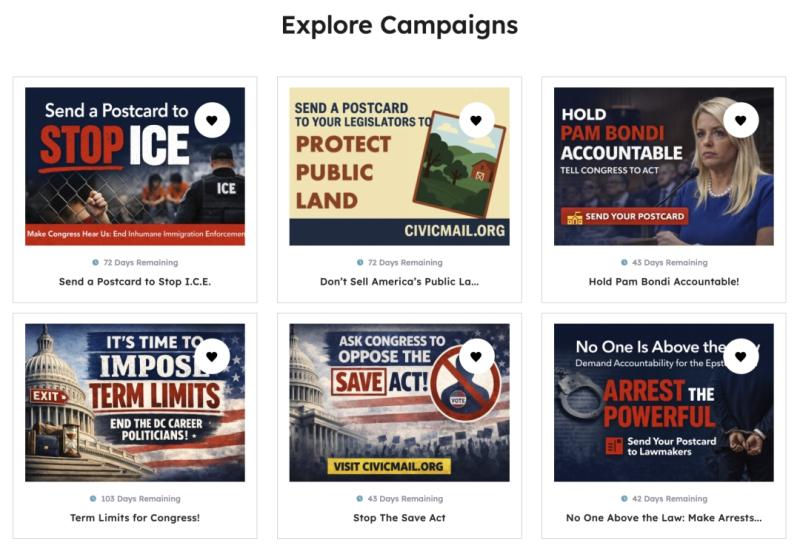

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for Polypropylene

Polypropylene Market: Technological Advances and Market Evolution in Polypropyle …

Polypropylene Market Description :

This comprehensive study delves into the latest revenue and market trends within the "Polypropylene Market". It emphasizes an overview, definition, and structural analysis while focusing on proactive and pre-planned management approaches. This report hones in on pivotal factors influencing the Polypropylene Market, such as gross margin, costs, market share, capacity utilization, and supply, enabling a nuanced evaluation of its future potential in the coming years. By presenting…

Polypropylene and Polypropylene Composites Market 2023 Size, Share, Industry, Fo …

The Polypropylene and Polypropylene Composites Market 2023 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the global Polypropylene and Polypropylene Composites market. This report explores all the key factors affecting the growth of the global…

Polypropylene and Polypropylene Composites Market Size, Share | Growth - 2030

Exclusive Report by Ameco Research: Polypropylene and Polypropylene Composites Market Size Projected to Reach USD 115 Billion by 2030, Growing at 8.20% CAGR

Ameco Research is proud to announce the launch of its latest market research report, Polypropylene and Polypropylene Composites Market. This comprehensive report provides in-depth analysis and insights into the current market trends and future projections in the Industry/Market Segment. Ameco Research has been at the forefront of…

Global Polypropylene and Polypropylene Composites Market Research Trends Analysi …

The polypropylene and polypropylene composites market is estimated to grow at a compound annual growth rate of 8.80% for the forecast period of 2023 to 2032.

Propene is polymerized to produce polypropylene and polypropylene composites. It is the most adaptable and versatile fibre with a variety of uses. It is transformed into fibres for textiles, carpets, garments, and bed sheets, among other things, as well as a film for packaging and…

Polypropylene Foam Market: Information by Type (Expanded Polypropylene (EPP) Foa …

Polypropylene foam — a lightweight thermoplastic made from polypropylene resin — exhibits superior properties, such as a high coefficient of friction, low density, stability across a wide temperature range, outstanding breathability, flexibility, and a buoyant nature. These favorable characteristics drive its adoption in the automotive, packaging, consumer durables, and construction industries, over counterparts such as polyethylene and polystyrene foams in applications.

The rising demand for lightweight automobiles, the development and growth…

Polypropylene and Polypropylene Composites Market with Development Factors, Inve …

According to a new report published by Allied Market Research, titled, Global Polypropylene and Polypropylene Composites Market for Injection Molding by Product, Fiber Type, and Application: Global Opportunity Analysis and Industry Forecast, 2017-2023, the global polypropylene and polypropylene composites market for injection molding was valued at $54,703 million in 2016, and is projected to reach $78,381 million by 2023, growing at a CAGR of 5.1% from 2017 to 2023. The…