Press release

Plastic Compounding Market: Trends, Growth Drivers and Future Outlook

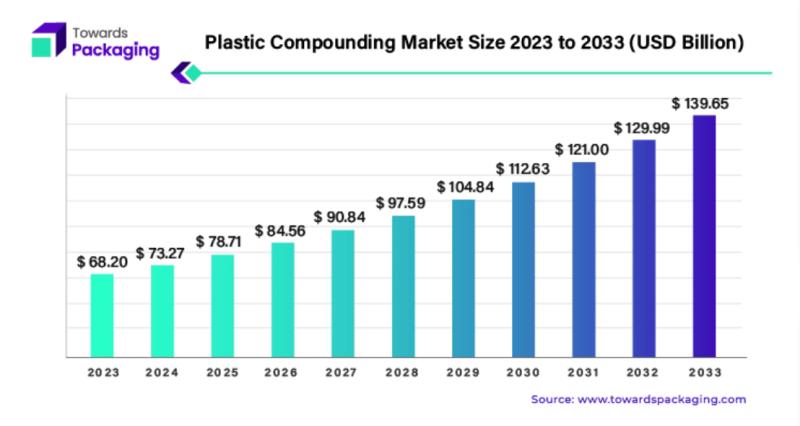

The global plastic compounding market was valued at US$ 68.2 billion in 2023 and is projected to grow to US$ 139.65 billion by 2033, reflecting a compound annual growth rate (CAGR) of 7.43% from 2024 to 2033.Exploring the Expanding Plastic Compounding Market: Key Trends, Benefits, and Future Prospects

The plastic compounding industry has become a pivotal component in manufacturing, offering a wide range of benefits, including cost efficiency, sustainability, and enhanced material performance. As the demand for advanced plastics continues to grow, the industry has found significant applications across various sectors such as aerospace, medical devices, automotive, packaging, consumer goods, and electronics. The unique properties imparted by plastic compounding, like improved flame retardancy, strength, and durability, are key drivers for the market's expansion.

Understanding Plastic Compounding

Plastic compounding refers to the process of manufacturing compounded plastics by blending different polymers, colorants, reinforcements, fillers, and additives. The goal is to enhance the base polymer's properties, making it more versatile and capable of fulfilling specific industrial requirements. Plastic compounds are engineered to provide enhanced characteristics such as improved chemical, electrical, thermal, or mechanical properties. These characteristics make them suitable for a wide range of applications where standard polymers fall short.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5199

The versatility of plastic compounding allows for the creation of materials with customized colors, UV tolerance, fire retardation, and food safety properties. This customization is driving the widespread adoption of compounded plastics in sectors ranging from packaging to industrial machinery, medical devices, and automotive manufacturing.

Key Market Trends and Insights

1. Asia Pacific Leads the Market

In 2023, Asia Pacific dominated the global plastic compounding market, accounting for the largest revenue share of 45%. The region's significant growth can be attributed to its robust manufacturing sector, increasing demand for plastics, and advancements in compounding technology. Countries like China and India are driving the market's growth due to the expanding automotive, packaging, and construction industries.

2. Source Segmentation: Fossil-Based vs. Recycled

By source, the fossil-based segment held the largest revenue share of 57% in 2023. However, the demand for sustainable materials is on the rise, with the recycled segment expected to witness the fastest growth during the forecast period. This shift towards recycled materials reflects the global push for sustainability and reducing plastic waste, aligning with the growing emphasis on environmental conservation.

3. Polypropylene Takes the Lead

In terms of product type, polypropylene (PP) dominated the market, generating more than 31% of the total revenue share in 2023. Polyethylene (PE) is also gaining momentum, with this segment estimated to be the fastest-growing during the forecast period, driven by its use in a wide range of applications, including packaging and consumer goods.

4. Automotive and Packaging Drive Demand

The automotive sector remains the largest application for plastic compounding, accounting for 26% of the market's revenue share in 2023. The growth in this segment is fueled by the increasing use of lightweight and durable plastic components in vehicles, helping to improve fuel efficiency and reduce emissions. On the other hand, the packaging industry is expected to witness the fastest growth due to the rise in e-commerce, demand for food safety, and the shift toward sustainable packaging solutions.

Factors Fueling Market Growth

1. Improved Material Performance

Plastic compounding offers superior material performance compared to basic polymers, enabling manufacturers to create materials that meet stringent industry standards. The enhanced properties, including flame retardancy, electrical insulation, and mechanical strength, provide significant advantages over traditional materials. The ability to customize plastic compounds for specific performance characteristics has contributed to the market's growth.

2. Versatility and Customization

The versatility of plastic compounding is one of its most attractive features. Manufacturers can create materials tailored to meet specific requirements, such as color, strength, fire resistance, or UV stability. This customization makes compounded plastics suitable for a wide variety of applications, from medical devices to aerospace components.

3. Sustainability

Sustainability has become a critical factor in driving the plastic compounding market. With growing environmental concerns, manufacturers are increasingly turning to recycled plastics and bio-based additives to create more sustainable compounds. These efforts align with global sustainability goals, helping to reduce the environmental impact of plastic products while maintaining performance standards.

4. Cost and Processing Efficiency

Plastic compounding also offers cost-efficiency by improving production processes. By optimizing material usage and reducing waste, compounding helps manufacturers save time and labor during production. The ability to create high-performance materials without compromising on quality contributes to the growth of the market, especially in cost-sensitive industries such as packaging.

Market Dynamics

Drivers of Market Growth

The increasing demand for plastic products across various sectors, including automotive, construction, and packaging, is one of the primary drivers of market growth. Plastics offer numerous advantages, including lightweight properties, strength, durability, and resistance to chemicals and environmental stress. Their ability to be molded into various shapes and sizes further contributes to their widespread use.

The automotive industry, in particular, is a significant driver due to the demand for lightweight components that contribute to better fuel efficiency. The packaging sector also remains a dominant force, especially with the rise of e-commerce and the growing need for food safety and sustainable packaging solutions.

Restraints and Challenges

While the market is poised for growth, several challenges may hinder its expansion. One of the primary concerns is the adverse health effects associated with certain additives used in plastic compounding. Endocrine disruptors, carcinogens, and direct toxicity are significant health risks, particularly when materials like DEHP (diethyl hexyl phthalate), mercury, lead, and cadmium are involved. Additionally, the environmental impact of non-biodegradable plastics and microplastics poses significant concerns.

Another challenge is the high cost of advanced compounding equipment and the complexities involved in ensuring consistent quality control. Variations in compounding processes, including inconsistent mixing and melt profiles, can lead to defects in the final product, affecting its performance and overall market appeal.

Opportunities in Advanced Technology

Despite these challenges, there is significant opportunity for growth through advancements in compounding technology. The development of bio-based plastics, sustainable additives, and more efficient production processes offers a pathway to a greener, more environmentally friendly future. Innovations in compounding techniques can help address the challenges of quality control, equipment costs, and environmental concerns.

The unique requirements of different industries-such as healthcare, construction, and electronics-also present opportunities for tailored compounding solutions. As manufacturers look to meet the specific needs of each sector, the demand for customized plastic compounds is expected to rise.

The Expanding Plastic Compounding Market: Trends, Insights, and Key Developments

The plastic compounding market has experienced significant growth in recent years, driven by innovations in material composition, applications, and regional developments. As the demand for advanced plastic materials continues to rise across various industries, a deeper look into the current market segments, regional dynamics, and emerging trends is essential for understanding its future trajectory.

Fossil-Based Plastics: Dominating the Market

In 2023, the fossil-based segment held a dominant position in the plastic compounding market, a trend that is expected to continue in the near future. Fossil-based plastic compounding primarily relies on hydrocarbons derived from non-renewable sources such as oil and natural gas. Popular materials in this category include polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET), and polyvinyl chloride (PVC). These materials are renowned for their exceptional durability, versatility, and lightweight properties.

Fossil-based plastics are widely utilized in applications such as packaging, automotive parts, and construction, due to their ability to replace heavier metals. Their lightweight nature not only reduces transportation costs but also contributes to energy efficiency. Furthermore, fossil-based plastics are integral to the food packaging industry, as they help extend shelf life by providing a protective barrier against environmental elements.

The growth of the fossil-based segment is largely attributed to these functional benefits, which align with consumer demand for cost-effective and high-performance materials.

The Recycled Segment: Accelerating Sustainability

While the fossil-based segment remains dominant, the recycled plastics segment is the fastest-growing category in the plastic compounding market. Recycling plastic is an essential step in improving sustainability, and it plays a pivotal role in reducing the environmental impact of plastic waste.

The compounding process in recycling involves transforming resized or shredded plastic waste into usable products. These plastics are reformed into pellets, which can then be used to produce new items. This process not only helps to conserve resources but also supports the circular economy by improving the recyclability of plastic materials.

As concerns over plastic pollution intensify, especially regarding health risks, environmental contamination, and threats to wildlife, the demand for recycled plastics has surged. Recycling mitigates these issues by reducing the need for new raw materials and decreasing the volume of plastic waste in landfills and oceans.

Moreover, advancements in plastic compounding techniques enhance the quality and durability of recycled products, further bolstering their appeal to manufacturers.

Bio-Based Plastics: The Future of Sustainable Compounding

Bio-based plastics are emerging as a significant player in the plastic compounding market, offering a sustainable alternative to fossil-based options. These plastics are derived from renewable biomass sources, including food waste, agricultural residues, and plant-based oils.

The bio-based plastic compounding process involves using additives and fillers to enhance the properties of biodegradable polymers. The resulting bio-based plastics offer numerous advantages over traditional materials, such as a lower carbon footprint, biodegradability, and reduced dependency on fossil fuels. Furthermore, they present an opportunity for manufacturers to align with sustainability goals, which are increasingly important to consumers and regulatory bodies alike.

Bio-based plastics also help improve the end-of-life scenarios for products, making them easier to recycle or dispose of responsibly. This segment is expected to experience significant growth in the coming years, as both businesses and consumers seek to reduce their environmental impact.

Key Products Driving Market Growth

Polypropylene (PP) and polyethylene (PE) are the two most prominent materials in the plastic compounding market. PP, which dominated the market in 2023, is valued for its excellent tensile strength, fatigue resistance, and chemical resistance. Its ability to withstand high temperatures, combined with its versatility and durability, makes it ideal for a wide range of applications, from automotive components to packaging and medical devices.

Polyethylene (PE), on the other hand, is anticipated to be the fastest-growing product segment during the forecast period. Known for its excellent gas and moisture barrier properties, PE is highly sought after for applications in packaging, automotive, and consumer goods. Its eco-friendly characteristics, including recyclability and lightweight nature, make it a preferred choice for many manufacturers focused on sustainability.

Application Insights: Automotive and Packaging Lead the Way

In 2023, the automotive industry was the largest application segment for plastic compounding, with plastics increasingly replacing metal components in vehicles. This shift is driven by several factors, including the need for lighter materials to improve fuel efficiency and the growing demand for electric vehicles (EVs). Plastic compounds offer numerous advantages in automotive applications, such as design flexibility, durability, and cost-effectiveness. They are used in a wide range of components, from exterior body panels to interior trims and engine parts.

The packaging industry, however, is expected to emerge as the fastest-growing segment during the forecast period. The use of plastic compounds in packaging offers many benefits, including protection against moisture, durability, and cost-efficiency. Additionally, plastic packaging is lighter than alternatives like glass and metal, which helps reduce transportation costs and carbon emissions. With the increasing demand for sustainable packaging solutions, the packaging sector's reliance on recycled and bio-based plastics is expected to accelerate.

Regional Dynamics: Asia Pacific Leading the Charge

The Asia Pacific (APAC) region was the largest market for plastic compounding in 2023, accounting for 25% of global market share. The rapid industrialization and urbanization in emerging economies like China, India, and Vietnam are driving the growth of the plastic compounding market in the region. APAC's expanding manufacturing capabilities, coupled with the growing demand for consumer electronics, automotive parts, and packaging materials, make it a key player in the global market.

The launch of new compounding facilities in countries like India further

underscores the region's strategic importance. In December 2023, Sirmax Group, an Italian compounder, inaugurated a new facility in India to produce polypropylene compounds, bio-compounds, and recycled polymers. Meanwhile, Dow and SCG Chemicals signed a partnership to enhance plastic waste recycling efforts in the region.

Recent Developments: Technological Advancements and Strategic Partnerships

Several key developments have shaped the plastic compounding market in recent months. In October 2023, Covestro, a Germany-based manufacturer, inaugurated a new compounding line for polycarbonates in Shanghai, with an annual processing capacity of 25,000 tons. This new line aims to meet the growing demand for sustainable plastic materials in Asia.

In May 2024, EcoCortec, a subsidiary of Cortec Corporation, launched

compounding operations for VpCI polymers and bio-resins, providing high-quality films for various industrial applications. Additionally, Borealis introduced an advanced compounding line in Belgium for recycled polyolefins (rPO), converting post-consumer waste into high-quality polyethylene and polypropylene materials.

These innovations reflect the industry's ongoing commitment to improving sustainability through advanced compounding technologies and strategic partnerships.

Leading Companies in Plastic Compounding

• Ravago

• Polyvisions, Inc.

• Solvay

• LANXESS

• TEIJIN LIMITED

• Arkema

• Covestro AG

• DuPont de Nemours, Inc.

• SABIC

• BASF SE

Source: https://www.towardspackaging.com/insights/plastic-compounding-market-sizing

Baner

Buy Premium Global Insight: https://www.towardspackaging.com/price/5199

Review the Full TOC for the Plastic Compounding Market Report: https://www.towardspackaging.com/table-of-content/plastic-compounding-market-sizing

Get the latest insights on packaging industry segmentation with our Annual Membership - https://www.towardspackaging.com/get-an-annual-membership

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

Towards Healthcare: https://www.towardshealthcare.com

Towards Automotive: https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Plastic Compounding Market: Trends, Growth Drivers and Future Outlook here

News-ID: 3803789 • Views: …

More Releases from Towards Packaging

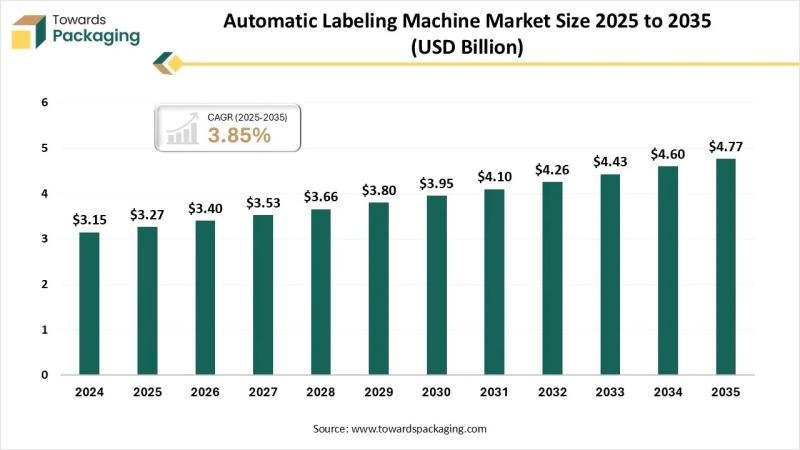

Automatic Labeling Machine Market Set for Strong Growth Through 2035

The global automatic labeling machine market is poised for steady expansion, rising from USD 3.4 billion in 2026 to USD 4.77 billion by 2035 at a CAGR of 3.85%. Demand is being driven by rapid automation in packaging lines, stringent labeling regulations, and the shift toward high-speed, error-free production across industries.

Download Sample: https://www.towardspackaging.com/download-sample/5882

Self-adhesive labeling systems currently hold the largest share at 39%, supported by their versatility and cost efficiency. Meanwhile,…

Unleashing Growth in the Liquid Packaging Market with Strategic Innovations

The liquid packaging industry is experiencing remarkable growth, with projections indicating an increase from USD 397.36 billion in 2025 to USD 645.43 billion by 2034. This growth, at a compound annual growth rate (CAGR) of 5.7%, signifies the expanding demand for liquid packaging solutions across a variety of sectors. As we delve into the market dynamics, it becomes clear that the liquid packaging sector is evolving rapidly, with several key…

Advancements in Hot-Fill Food Packaging Paving the Way for a Sustainable Future

The global hot-fill food packaging market is experiencing a steady rise, with an expected market value of USD 71.26 billion by 2033, up from USD 49.85 billion in 2023. This growth is projected to follow a compound annual growth rate (CAGR) of 3.76% from 2024 to 2033, reflecting the increasing demand for innovative packaging solutions in the food and beverage sector.

Download a Brochure of Hot-fill Food Packaging Market: https://www.towardspackaging.com/download-brochure/5266

Hot-Fill…

Driving Growth and Innovation in the Plastic Bag Market

The plastic bag market is undergoing significant growth, with its value reaching an estimated US$ 25.10 billion in 2023. Projections suggest that this market could hit a substantial US$ 35.41 billion by 2033, marking a steady compound annual growth rate (CAGR) of 3.5% from 2024 to 2034. This growth is largely driven by the expanding needs of various industries for efficient and cost-effective packaging solutions.

Download a Brochure of Plastic Bag…

More Releases for Plastic

Plastic bottles at events - Better party with plastic

Partying, dancing, camping - festivals attract hundreds of thousands of visitors every year in Germany alone. One challenge: supply and safety. For this reason, drinks in glass bottles are banned at most events due to the risk of injury. Lightweight and unbreakable plastic bottles, on the other hand, are considered a safe and practical alternative. Not only that: they can even be used to make a musical instrument.

Festivals or pageants…

Plastic Pallet With Plastic Crate Use: Efficient Material Handling

When it comes to efficient moving and storage of goods, a combination of plastic pallets [https://www.agriculture-solution.com/plastic-pallet/]and plastic crates is a popular choice. They are widely used in various industries such as manufacturing, retail, agriculture, etc. for storage and transportation of goods. Plastic pallets are designed to provide a stable base for stacking and shipping goods, while plastic crates provide safe and protective containers for stored or transported items. Plastic pallets…

Plastic Granules Market to Witness Massive Growth by Balaji Plastic, Navkar Indu …

The Worldwide Plastic Granules Market has witnessed continuous growth in the past few years and is projected to grow at a good pace during the forecast period of 2023-2029. The exploration provides a 360° view and insights, highlighting major outcomes of Worldwide Plastic Granules industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improve profitability. Additionally, the study helps venture or emerging…

Insights on the Growth of Plastic Granules Market 2018 to 2025 | Profiling Key C …

UpMarketResearch offers a Latest report on “Plastic Granules Market Analysis & Forecast 2018-2025” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 114 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy of This Report@ https://www.upmarketresearch.com/home/requested_sample/49052

Plastic Granules research report delivers a close watch on leading competitors with strategic…

Agriculture Film Market SWOT Analysis of Leading Key Players Shandong Tianhe Pla …

HTF MI recently introduced Global Agriculture Film Market study with in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status to 2023. The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence and some of the key players from the complete study are British Polythene Industries (BPI), Trioplast, Berry Plastics, Armando Alvarez, Polypak, Barbier…

Building Materials Market 218 : Hepworth, National Plastic Industry, Hira Indust …

Building materials in this report covered the PVC pipes and fittings, PPR pipes and fittings, PE pipes and fittings, fabrication, ducts systems for infrastructure, valves and pumps and electrical conduits PVC systems.

At present, Hepworth, National Plastic Industry, Hira Industries, Florance Plastic Industries, Polyfab Plastic Industry, MPI, Union Pipes Industry, ANABEEB, Borouge and ACO Group are the UAE leading suppliers of the building materials, and top ten of them shared about…