Press release

Metal Injection Molding Market to Hit USD 10.83 Bn by 2030, Growing at 11.9% CAGR

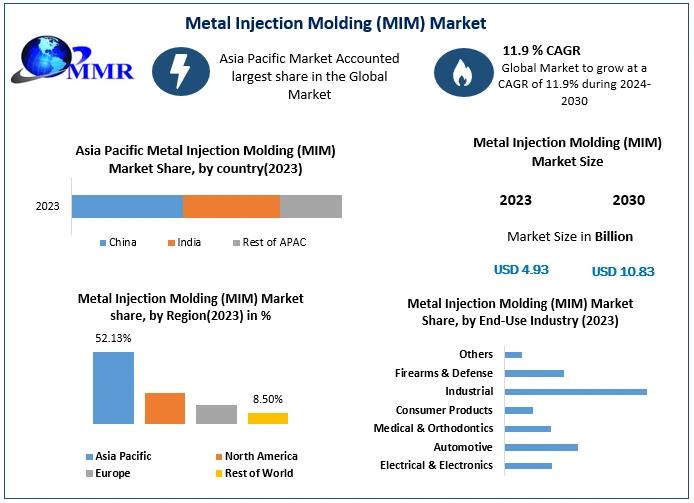

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐭𝐨 𝐖𝐢𝐭𝐧𝐞𝐬𝐬 𝐔𝐧𝐩𝐫𝐞𝐜𝐞𝐝𝐞𝐧𝐭𝐞𝐝 𝐆𝐫𝐨𝐰𝐭𝐡 𝐀𝐜𝐫𝐨𝐬𝐬 𝐊𝐞𝐲 𝐑𝐞𝐠𝐢𝐨𝐧𝐬 𝐛𝐲 𝟐𝟎𝟑𝟎The global Metal Injection Molding (MIM) market is experiencing remarkable growth, driven by advancements in manufacturing technologies, rising demand for intricate components, and increasing applications across industries such as automotive, electronics, and medical. According to the latest analysis, the global MIM market was valued at USD 4.93 billion in 2023 and is projected to grow at a CAGR of 11.9% from 2024 to 2030, reaching a market size of USD 10.83 billion by the end of the forecast period.

𝐆𝐫𝐚𝐛 𝐲𝐨𝐮𝐫 𝐬𝐚𝐦𝐩𝐥𝐞 𝐜𝐨𝐩𝐲 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐫𝐞𝐩𝐨𝐫𝐭 𝐧𝐨𝐰: https://www.maximizemarketresearch.com/request-sample/1733/

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐓𝐫𝐞𝐧𝐝𝐬 𝐢𝐧 𝐓𝐡𝐚𝐢𝐥𝐚𝐧𝐝: 𝐒𝐡𝐢𝐟𝐭𝐢𝐧𝐠 𝐓𝐨𝐰𝐚𝐫𝐝𝐬 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠

Thailand has emerged as a significant player in the MIM industry, with local companies focusing on adopting cutting-edge technologies. Key mergers include ABC Ltd.'s acquisition of local manufacturers to streamline production. The market is expected to grow steadily, driven by demand from the automotive and electronics sectors.

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐆𝐫𝐨𝐰𝐭𝐡 𝐢𝐧 𝐉𝐚𝐩𝐚𝐧: 𝐏𝐢𝐨𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐑&𝐃 𝐢𝐧 𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠

Japan leads the MIM market in innovation, with companies like 𝗡𝗶𝗽𝗽𝗼𝗻 𝗠𝗲𝘁𝗮𝗹𝘄𝗼𝗿𝗸𝘀 investing heavily in research and development. Recent collaborations and partnerships have enhanced capabilities for producing intricate components for the medical and aerospace industries. Japan's market continues to thrive due to its emphasis on high-quality manufacturing.

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐨𝐮𝐭𝐡 𝐊𝐨𝐫𝐞𝐚: 𝐎𝐩𝐩𝐨𝐫𝐭𝐮𝐧𝐢𝐭𝐲 𝐢𝐧 𝐀𝐮𝐭𝐨𝐦𝐨𝐭𝐢𝐯𝐞 𝐚𝐧𝐝 𝐄𝐥𝐞𝐜𝐭𝐫𝐨𝐧𝐢𝐜𝐬 𝐒𝐞𝐜𝐭𝐨𝐫𝐬

South Korea's MIM market is expanding, driven by rising demand from the automotive and electronics sectors. Notable mergers, such as 𝐒𝐚𝐦𝐬𝐮𝐧𝐠 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 𝐏𝐚𝐫𝐭𝐬' acquisition of local MIM firms, have strengthened South Korea's position in the global market. The government's focus on smart manufacturing further supports this growth.

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐂𝐨𝐧𝐬𝐨𝐥𝐢𝐝𝐚𝐭𝐢𝐨𝐧 𝐢𝐧 𝐒𝐢𝐧𝐠𝐚𝐩𝐨𝐫𝐞:

Singapore's MIM industry benefits from its strategic location and robust infrastructure. Recent consolidations, including 𝐓𝐞𝐜𝐡𝐆𝐥𝐨𝐛𝐚𝐥'𝐬 𝐚𝐜𝐪𝐮𝐢𝐬𝐢𝐭𝐢𝐨𝐧 𝐨𝐟 𝐌𝐢𝐜𝐫𝐨𝐌𝐈𝐌 𝐋𝐭𝐝., have increased production efficiency. With an emphasis on precision engineering, Singapore is poised for continued growth in the MIM sector.

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐔𝐩𝐝𝐚𝐭𝐢𝐨𝐧 𝐢𝐧 𝐭𝐡𝐞 𝐔𝐒: 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐓𝐡𝐫𝐨𝐮𝐠𝐡 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐈𝐧𝐯𝐞𝐬𝐭𝐦𝐞𝐧𝐭𝐬

The US holds a significant share in the global MIM market, driven by advancements in medical and defense applications. Recent developments include MetalForge Inc.'s acquisition of emerging MIM startups to enhance technological capabilities. Federal funding for precision manufacturing is further propelling the market's growth trajectory.

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐢𝐧 𝐄𝐮𝐫𝐨𝐩𝐞: 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐚𝐧𝐝 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐢𝐧 𝐅𝐨𝐜𝐮𝐬

Europe's MIM market is driven by increasing adoption of sustainable practices. Key players such as 𝐄𝐮𝐫𝐨𝐌𝐈𝐌 𝐂𝐨𝐫𝐩. have invested in green technologies to reduce environmental impact. Recent mergers, like 𝐆𝐫𝐞𝐞𝐧𝐓𝐞𝐜𝐡 𝐌𝐨𝐥𝐝𝐢𝐧𝐠'𝐬 𝐚𝐜𝐪𝐮𝐢𝐬𝐢𝐭𝐢𝐨𝐧 𝐨𝐟 𝐄𝐜𝐨𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧, highlight Europe's commitment to innovation and sustainability.

𝐈𝐧𝐭𝐞𝐫𝐞𝐬𝐭𝐞𝐝 𝐭𝐨 𝐭𝐚𝐤𝐞 𝐚 𝐬𝐧𝐞𝐚𝐤 𝐩𝐞𝐞𝐤? 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐚 𝐬𝐚𝐦𝐩𝐥𝐞 𝐜𝐨𝐩𝐲 𝐨𝐟 𝐭𝐡𝐞 𝐫𝐞𝐩𝐨𝐫𝐭 𝐭𝐨 𝐬𝐞𝐞 𝐰𝐡𝐚𝐭'𝐬 𝐢𝐧𝐬𝐢𝐝𝐞: https://www.maximizemarketresearch.com/request-sample/1733/

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬:

𝐁𝐲 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐓𝐲𝐩𝐞

Stainless Steel

Low Alloy Steel

Soft Magnetic Material

Others (Tool Steel, Titanium, Tungsten)

𝐁𝐲 𝐄𝐧𝐝-𝐔𝐬𝐞 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲

Electrical & Electronics

Automotive

Medical & Orthodontics

Consumer Products

Industrial

Firearms & Defense

Others

Stainless steel, low alloy steel, soft magnetic material, and others (tool steel, titanium, and tungsten) are the market segments based on material type. Over the course of the forecast period, the Metal Injection Molding (MIM) market is anticipated to be dominated by the stainless steel segment, which dominated the market in 2023. MIM uses stainless steel because of its exceptional resistance to corrosion. This makes it appropriate for use in sectors where exposure to diverse environmental conditions is frequent, like consumer electronics, automotive, healthcare, and aerospace. Stainless steel is renowned for its exceptional durability and strength.

𝐅𝐨𝐫 𝐚 𝐭𝐡𝐨𝐫𝐨𝐮𝐠𝐡 𝐮𝐧𝐝𝐞𝐫𝐬𝐭𝐚𝐧𝐝𝐢𝐧𝐠 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐬𝐭𝐮𝐝𝐲, 𝐫𝐞𝐟𝐞𝐫 𝐭𝐨 𝐭𝐡𝐞 𝐟𝐨𝐥𝐥𝐨𝐰𝐢𝐧𝐠 𝐰𝐞𝐛𝐩𝐚𝐠𝐞: https://www.maximizemarketresearch.com/request-sample/1733/

𝐌𝐞𝐭𝐚𝐥 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐥𝐞𝐚𝐝𝐢𝐧𝐠 𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 𝐈𝐧𝐜𝐥𝐮𝐝𝐞:

North America:

1. Dynacast International (United States)

2. ARC Group Worldwide (United States)

3. Phillips-Medisize Corporation (United States)

4. Smith Metal Products (United States)

5. FloMet LLC (United States)

6. Parmatech Corporation (United States)

7. NetShape Technologies (United States)

8. Form Technologies (United States)

9. CMG Technologies (United States)

10. Kinetics (United States)

11. Flomet, LLC (United States)

12. Precision Engineered Products (PEP) (United States)

13. MICRO (US)

14. Advanced Powder Products, Inc. (Philipsburg, Pennsylvania, US)

15. HIPERBARIC (Miami, Florida)

16. MPP (Noblesville, IN, US)

Asia Pacific:

1. Indo-MIM (India)

2. MIM Tech (Taiwan)

3. Micro Metal Powder (MMP) (Japan)

4. Amphenol East Asia Limited (Hong Kong)

5. Indo-US MIM Tec Pvt. Ltd. (India)

6. Dou Yee Technologies (Singapore)

7. Sints Precision Technology Co., Ltd. (China)

Europe:

1. Dean Group International (United Kingdom)

2. Future MIM (United Kingdom)

𝐒𝐭𝐚𝐲 𝐚𝐡𝐞𝐚𝐝 𝐨𝐟 𝐭𝐡𝐞 𝐜𝐮𝐫𝐯𝐞 𝐰𝐢𝐭𝐡 𝐭𝐡𝐞 𝐭𝐫𝐞𝐧𝐝𝐢𝐧𝐠 𝐫𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐟𝐫𝐨𝐦 𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡:

Global Water-Based Enamel Market https://www.maximizemarketresearch.com/market-report/global-water-based-enamel-market/116497/

Global Embedded AI Computing Platforms Market https://www.maximizemarketresearch.com/market-report/global-embedded-ai-computing-platforms-market/111905/

Global Eye Cosmetic Packaging Market https://www.maximizemarketresearch.com/market-report/global-eye-cosmetic-packaging-market/26227/

UK Dental Services Market https://www.maximizemarketresearch.com/market-report/uk-dental-services-market/222401/

Global Phosphate Ester Market https://www.maximizemarketresearch.com/market-report/phosphate-ester-market/2600/

Global Chromium Oxide Market https://www.maximizemarketresearch.com/market-report/global-chromium-oxide-market/66331/

Integrated Systems Market https://www.maximizemarketresearch.com/market-report/integrated-systems-market/65616/

Configuration Management Market https://www.maximizemarketresearch.com/market-report/global-configuration-management-market/62980/

Global Advanced Glass Market https://www.maximizemarketresearch.com/market-report/global-advanced-glass-market/29073/

Global Mobile Photo Printer Market https://www.maximizemarketresearch.com/market-report/global-mobile-photo-printer-market/28119/

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬

MAXIMIZE MARKET RESEARCH PVT. LTD.

3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

sales@maximizemarketresearch.com

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding Market to Hit USD 10.83 Bn by 2030, Growing at 11.9% CAGR here

News-ID: 3791920 • Views: …

More Releases from Maximize Market Research Pvt. Ltd.

Commercial Kitchen Appliances Market Poised for Robust Growth, Expected to Reach …

The global Commercial Kitchen Appliances Market, valued at US$ 101.65 billion in 2023, is witnessing strong momentum driven by the rapid expansion of the foodservice industry, technological innovation, and evolving consumer lifestyles. According to the latest market analysis, the industry is projected to grow at a compound annual growth rate (CAGR) of 6.7% from 2024 to 2030, reaching nearly US$ 160.05 billion by the end of the forecast period.

Commercial kitchen…

E-Bike Market Poised for Robust Expansion, Projected to Reach USD 153.42 Billion …

The global E-Bike Market is entering a transformative growth phase, underpinned by accelerating demand for eco-friendly transportation, rapid advances in battery and motor technologies, and strong policy support for sustainable urban mobility. Valued at USD 60.65 Billion in 2024, the market is projected to expand at a compound annual growth rate (CAGR) of 12.3% from 2025 to 2032, reaching nearly USD 153.42 Billion by 2032. As cities worldwide seek to…

Data Center Liquid Immersion Cooling Market Set for Rapid Expansion, Driven by H …

Data Center Liquid Immersion Cooling Market to Grow from USD 640.94 Million in 2023 to USD 3,340.83 Million by 2030, Registering a Robust CAGR of 26.6% (2024-2030)

The global Data Center Liquid Immersion Cooling Market is witnessing a transformative phase as data center operators worldwide seek advanced, energy-efficient cooling solutions to address rising power densities, sustainability mandates, and escalating operational costs. Valued at USD 640.94 million in 2023, the market…

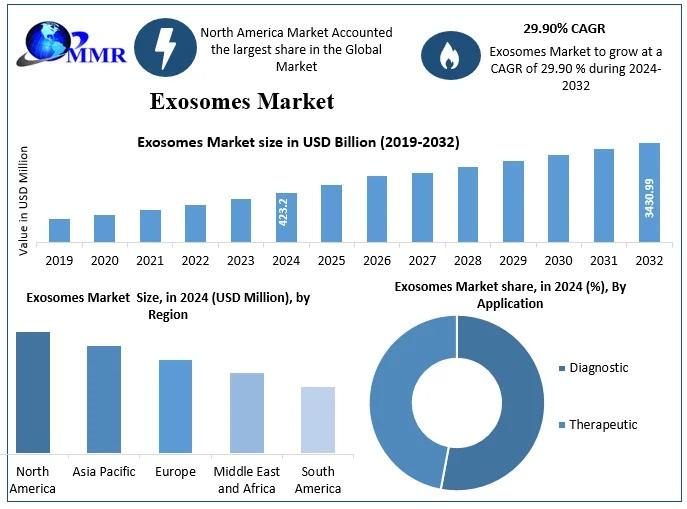

Exosomes Market Forecast: USD 3,430.99 Million Opportunity by 2032

Exosomes Market size was valued at USD 423.2 Mn in 2024 and is expected to reach USD 3430.99 Mn by 2032, at a CAGR of 29.90

The global exosomes market is currently poised for explosive growth, fundamentally driven by the paradigm shift toward non-invasive diagnostics and the rising prominence of "liquid biopsies" in oncology. Once considered mere cellular waste, these extracellular vesicles are now recognized as critical mediators of intercellular communication,…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…