Press release

Tempered Glass Manufacturing Plant Report 2024: Project Cost, Machinery Requirement, and Setup Details

Tempered glass represents a type of safety glass that has been heat-treated to enhance its strength. It is known for its ability to resist impact and thermal stress, which makes it an ideal choice for various applications, especially where safety and reliability are paramount. One of the most notable features of tempered glass is its capability to break into small, blunt pieces when shattered, reducing the risk of injury. As a result, it is widely used in products like automotive windows, shower doors, glass railings, and smartphone screens, where strength and safety are critical.The increasing demand for tempered glass is primarily driven by the growing need for durable and safe materials in industries such as construction, automotive, and electronics. The construction industry, in particular, has seen significant growth in the use of tempered glass due to its aesthetic appeal and safety benefits. In the automotive industry, tempered glass is essential for the manufacturing of side and rear windows, contributing to vehicle safety by minimizing the risk of injury in an accident. Additionally, the rise in demand for high-end electronics such as smartphones, tablets, and televisions has further fueled the tempered glass market, as it provides scratch resistance and protection for fragile screens. Several trends are shaping the tempered glass market, with technological advancements and changing consumer preferences at the forefront.

IMARC Group's report titled "Tempered Glass Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for setting up a tempered glass manufacturing plant.

Request for a Sample Report: https://www.imarcgroup.com/tempered-glass-manufacturing-plant-project-report/requestsample

The report includes the following information:

Market Analysis:

One of the key trends is the increasing focus on sustainability. Manufacturers are adopting eco-friendly production methods and exploring the use of recyclable materials to meet the growing consumer demand for sustainable products. Another emerging trend is the rising popularity of tempered glass in the consumer electronics sector, driven by the demand for high-quality, durable, and aesthetically pleasing screens. As consumer expectations for the performance and design of electronic devices continue to rise, tempered glass is poised to play an increasingly important role in meeting these needs. With innovations like anti-glare and anti-fingerprint coatings, the tempered glass market is expected to continue evolving, fulfilling the needs of diverse industries and contributing to the development of safer, more efficient products.

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Buy Now: https://www.imarcgroup.com/checkout?id=18057&method=402

Project Overview

This section offers detailed information related to the process flow and several unit operations involved in a tempered glass manufacturing plant project. Moreover, information related to raw material requirements and mass balance has further been provided in the report with a list of necessary technical tests as well as quality assurance criteria.

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Key Requirements and Costs

This section provides an analysis encompassing insights, including land location, selection criteria, location significance, environmental impact, and expenditure for tempered glass manufacturing plant setup. Besides this, the report further offers information related to plant layout and factors influencing the same. Additionally, other expenditures and requirements related to packaging, utilities, machinery, transportation, raw materials, and human resources have also been included in the report.

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

This section covers a comprehensive analysis of the project economics for setting up a tempered glass manufacturing plant. This comprises the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), taxation, depreciation, profitability analysis, payback period, NPV, income projections, liquidity analysis, uncertainty analysis, and sensitivity analysis.

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=18057&flag=C

Customization Available:

Production Capacity:

Draft the machinery selection and plant layout to align with the expected scale of production, which can range from small-scale operations to large industrial setups.

Automation Levels:

Modify the level of automation based on labor availability, budget constraints, and technical expertise from semi-automated processes to fully automated systems.

Location Adaptation:

Customize the plant's location to strategically align with local market demand, ensure efficient access to raw materials, utilize available labor resources, and adhere to regional regulatory requirements, thereby maximizing operational efficiency and cost-effectiveness.

Product Flexibility:

Encompass processes and machinery that can handle numerous product variations. This, in turn, can enable the plant to cater to diverse market demands.

Sustainability Features:

Incorporate various eco-friendly options, including renewable energy integration, waste management systems, energy-efficient machinery, etc., to meet sustainability goals.

Raw Material Sourcing:

Tailor the supply chain strategy to enable cost-effective and reliable access to raw materials specific to client requirements or the region.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Tempered Glass Manufacturing Plant Report 2024: Project Cost, Machinery Requirement, and Setup Details here

News-ID: 3784791 • Views: …

More Releases from IMARC Group

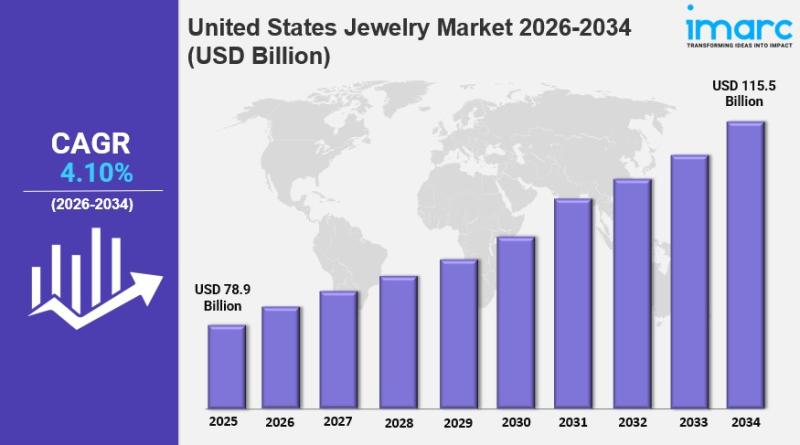

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…