Press release

Pneumatic Conveying System Market Size, Share and Industry Analysis, Report 2025-2033

Pneumatic Conveying System IndustrySummary:

● The global pneumatic conveying system market size reached USD 33.0 Billion in 2024.

● The market is expected to reach USD USD 48.8 Billion by 2033, exhibiting a growth rate (CAGR) of 4.4% during 2025-2033.

● Asia Pacific leads the market, accounting for the largest pneumatic conveying system market share.

● Positive pressure conveying represents the leading technology as they are versatile and can handle a diverse range of materials.

● Dilute phase conveying holds the largest market share.

● Food account for the majority of the market share as these systems ensure efficient handling of food ingredients.

● The growing focus on industrial automation is a primary driver of the pneumatic conveying system market.

● The pneumatic conveying system market growth and forecast highlight a significant rise due to the integration of smart sensors, automated controls, and predictive maintenance features.

Industry Trends and Drivers:

● Expanding applications in emerging economies:

The pneumatic conveying system market size is witnessing growth, driven by increasing industrialization and urbanization in emerging economies. Sectors like construction, mining, and chemicals are expanding rapidly, requiring efficient material handling systems. Pneumatic conveying systems offer a cost-effective and scalable solution to transport bulk materials in these industries, making them an essential part of infrastructure development. Additionally, government initiatives to boost industrial growth in regions such as Asia-Pacific are encouraging the adoption of these systems. With the rising emphasis on environmental regulations and sustainability, pneumatic conveying systems also provide a cleaner and more energy-efficient alternative compared to traditional conveying methods, contributing to their growing adoption worldwide.

● Rising demand for automation:

The growing focus on industrial automation is one of the significant pneumatic conveying system market trends propelling its expansion. Companies are increasingly adopting automated solutions to improve efficiency, consistency, and scalability in production processes. Pneumatic conveying systems eliminate manual handling, ensuring contamination-free material transfer, which is essential for industries like food processing and pharmaceuticals. The heightened emphasis on workplace safety and reducing labor dependency is also contributing to the rising pneumatic conveying system demand. Moreover, the systems' ability to adapt to different materials and applications makes them an indispensable component in modern automated production lines, further solidifying their market presence.

● Technological advancements:

The pneumatic conveying system market share is expanding due to continuous advancements in technology that enhance system efficiency and reliability. Modern pneumatic conveying systems are designed with smart sensors, automated controls, and predictive maintenance features, ensuring reduced downtime and operational costs. The incorporation of innovative designs allows these systems to handle a wide range of materials, from fine powders to granular substances, with minimal wear and tear. These advancements make pneumatic conveying systems a preferred choice across industries such as food, pharmaceuticals, and chemicals, where precision and hygiene are crucial. Additionally, the increasing adoption of Industry 4.0 practices has integrated data-driven solutions into pneumatic conveying systems, further boosting their appeal in manufacturing setups.

For an in-depth analysis, you can request a sample copy of the report: https://www.imarcgroup.com/pneumatic-conveying-system-market/requestsample

Pneumatic Conveying System Market Report Segmentation:

Breakup By Technology:

● Positive Pressure Conveying

● Vacuum Pressure Conveying

● Combination Conveying

Positive pressure conveying dominates the market as it is versatile and can handle a diverse range of materials.

Breakup By Operation:

● Dilute-phase Conveying

● Dense-phase Conveying

Dilute-phase holds the largest market share due to its efficient material transport capabilities.

Breakup By End User:

● Food

● Pharmaceuticals

● Rubber and Plastics

● Ceramic

● Mining

● Others

Food account for the majority of the market share as these systems provide a contamination-free method of transporting raw materials.

Breakup By Region:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

Asia Pacific holds the leading position owing to a large market for pneumatic conveying system driven by a rapid industrialization and infrastructural development activities.

Top Pneumatic Conveying System Market Leaders:

● Atlas Copco AB

● AZO GmbH + Co. KG

● Cyclonaire Corporation

● Dynamic Air Inc.

● Flexicon Corporation

● Gericke AG

● Hillenbrand Inc.

● Macawber Engineering Inc.

● Nilfisk Group

● Nol-Tec Systems Inc.

● Palamatic Process

● Schenck Process Holding GmbH

● VAC-U-MAX

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pneumatic Conveying System Market Size, Share and Industry Analysis, Report 2025-2033 here

News-ID: 3784724 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

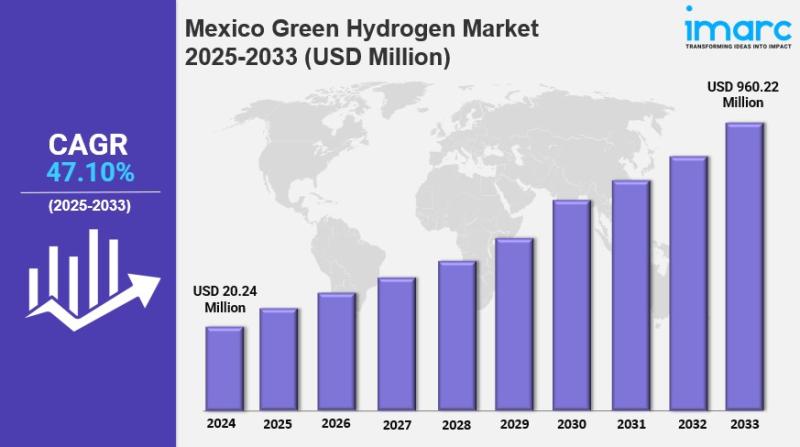

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Conveying

Increasing Automation Drives Growth In The Pneumatic Conveying System Market: Th …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Pneumatic Conveying Systems Market Size Growth Forecast: What to Expect by 2025?

The market for pneumatic conveying systems has been on a steady growth trajectory in the past few years. The market size will increase from $32.48 billion in 2024 to $33.95 billion in 2025, showcasing a compound annual…

Top Factor Driving Pneumatic Conveying Systems Market Growth in 2025: Increasing …

What industry-specific factors are fueling the growth of the pneumatic conveying systems market?

The progression of the pneumatic conveying systems market is anticipated to be fuelled by escalating automation. Automation involves employing mechanical or electronic devices to enable a device, process or system to function autonomously, thus replacing human labor. The surge in automation stems from technological advancements aimed at refining processes, enhancing efficiency, and bringing down labor expenses. Pneumatic conveying…

Vacuum Conveyor | Vacuum conveying system | Altomech Private Limited

Altomech Private Limited: Redefining Material Handling with Vacuum Conveying Systems

E-mail : marketing@altomech.com

Contact: 95851 31112

website: https://altomech.com/vacuum-conveying-system.php

Introduction:

Altomech Private Limited stands as a beacon of innovation in the realm of material handling solutions, offering state-of-the-art technologies tailored to the diverse needs of modern industries. At the forefront of their offerings are vacuum conveying systems, which have revolutionized the way materials are transported and processed in manufacturing facilities worldwide. This article explores the prowess…

Pneumatic Conveying System

Altomech is a renowned company that specializes in the design and manufacturing of advanced pneumatic conveying systems. Pneumatic conveying systems are vital in various industries for the efficient and dust-free transfer of bulk materials like powders, granules, and other particulate matter. Altomech has gained recognition for its innovative solutions and cutting-edge technology, making it a trusted partner for industries ranging from food and pharmaceuticals to chemicals and plastics.

Key Features and…

Industrial Explosives Market Conveying Valuable Data By 2024

The impact of COVID-19 pandemic can be felt across the chemical industry. The growing inability in the production and manufacturing processes, in the light of the self-quarantined workforce has caused a major disruption in the supply chain across the sector. Restrictions encouraged by this pandemic are obstructing the production of essentials such as life-saving drugs.

The nature of operation in chemical plants that cannot be easily stopped and started, makes the…

Global Conveying Equipment Market Research Report 2018-2023

Global Conveying Equipment on hardware showcase discovers application as merchandise transporter in a few ventures including metal mining and coal, power, nourishment and drinks, steelworks, airplane terminals, bond, and ports. The real favorable position offered by the passing on gear incorporates a decrease in the time required for creating in this manner expanding their operational productivity.

Get sample copy of report:

https://www.marketdensity.com/contact?ref=Sample&reportid=5773

Table of Contents

1 Conveying Equipment Market Overview

1.1 Product Overview…