Press release

Automotive Cleaning Wipes Manufacturing Plant Report 2024: Machinery Requirement, and Setup Details

Automotive cleaning wipes are a practical and efficient solution for maintaining the cleanliness and hygiene of vehicles. These wipes are specifically made to address various cleaning needs, ranging from interior surfaces such as dashboards, upholstery, and windows to exterior components like mirrors and body panels. Typically infused with cleaning agents, these wipes can effectively remove dirt, grease, and stains while leaving a polished finish. Their disposable nature adds to their convenience, eliminating the need for water or additional cleaning equipment. Widely utilized by car owners and professional detailing services, automotive cleaning wipes offer a time-saving, cost-effective alternative for keeping vehicles in pristine condition.The global automotive cleaning wipes market is primarily driven by the huge focus on vehicle aesthetics and hygiene. The growing awareness of the need to maintain vehicle interiors and exteriors free from dust, allergens, and bacteria is encouraging consumers to adopt efficient cleaning solutions. Furthermore, the rising ownership of vehicles, particularly in urban areas, is boosting the demand for easy-to-use, portable cleaning options. A notable trend is the increasing preference for biodegradable and eco-friendly automotive wipes, as consumers become more environmentally conscious. Additionally, the expanding automotive aftermarket and the surge in DIY car maintenance activities are further bolstering the market. With the integration of advanced materials and effective cleaning agents, automotive cleaning wipes continue to see rising adoption worldwide.

IMARC Group's report titled "Automotive Cleaning Wipes Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for setting up an automotive cleaning wipes manufacturing plant.

Request for a Sample Report: https://www.imarcgroup.com/automotive-cleaning-wipes-manufacturing-plant-project-report/requestsample

The report includes the following information:

Market Analysis:

Manufacturers are investing in research and development to create wipes that offer superior performance, such as anti-static or UV-protective properties, catering to the premium vehicle segment. Moreover, smart packaging solutions, such as resealable packs and moisture-lock technology, are enhancing product longevity and consumer convenience. The increasing integration of sustainable practices, including the use of biodegradable materials and non-toxic cleaning agents, aligns with the growing masses preference for environmentally responsible products. Looking ahead, the adoption of advanced technologies, such as antimicrobial formulations and customizable wipes for specific applications, is expected to redefine the market. These innovations, coupled with the steady growth in vehicle ownership and a focus on health and hygiene, are projected to drive the automotive cleaning wipes market into a promising future.

Market Trends

Market Breakup by Segment

Market Breakup by Region

Price Analysis

Impact of COVID-19

Market Forecast

Buy Now: https://www.imarcgroup.com/checkout?id=16073&method=402

Project Overview

This section offers detailed information related to the process flow and several unit operations involved in an automotive cleaning wipes manufacturing plant project. Moreover, information related to raw material requirements and mass balance has further been provided in the report with a list of necessary technical tests as well as quality assurance criteria.

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Key Requirements and Costs

This section provides an analysis encompassing insights, including land location, selection criteria, location significance, environmental impact, and expenditure for automotive cleaning wipes manufacturing plant setup. Besides this, the report further offers information related to plant layout and factors influencing the same. Additionally, other expenditures and requirements related to packaging, utilities, machinery, transportation, raw materials, and human resources have also been included in the report.

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Project Economics:

This section covers a comprehensive analysis of the project economics for setting up an automotive cleaning wipes manufacturing plant. This comprises the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), taxation, depreciation, profitability analysis, payback period, NPV, income projections, liquidity analysis, uncertainty analysis, and sensitivity analysis.

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=16073&flag=C

Customization Available:

Production Capacity:

Draft the machinery selection and plant layout to align with the expected scale of production, which can range from small-scale operations to large industrial setups.

Automation Levels:

Modify the level of automation based on labor availability, budget constraints, and technical expertise from semi-automated processes to fully automated systems.

Location Adaptation:

Customize the plant's location to strategically align with local market demand, ensure efficient access to raw materials, utilize available labor resources, and adhere to regional regulatory requirements, thereby maximizing operational efficiency and cost-effectiveness.

Product Flexibility:

Encompass processes and machinery that can handle numerous product variations. This, in turn, can enable the plant to cater to diverse market demands.

Sustainability Features:

Incorporate various eco-friendly options, including renewable energy integration, waste management systems, energy-efficient machinery, etc., to meet sustainability goals.

Raw Material Sourcing:

Tailor the supply chain strategy to enable cost-effective and reliable access to raw materials specific to client requirements or the region.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Cleaning Wipes Manufacturing Plant Report 2024: Machinery Requirement, and Setup Details here

News-ID: 3780995 • Views: …

More Releases from IMARC Group

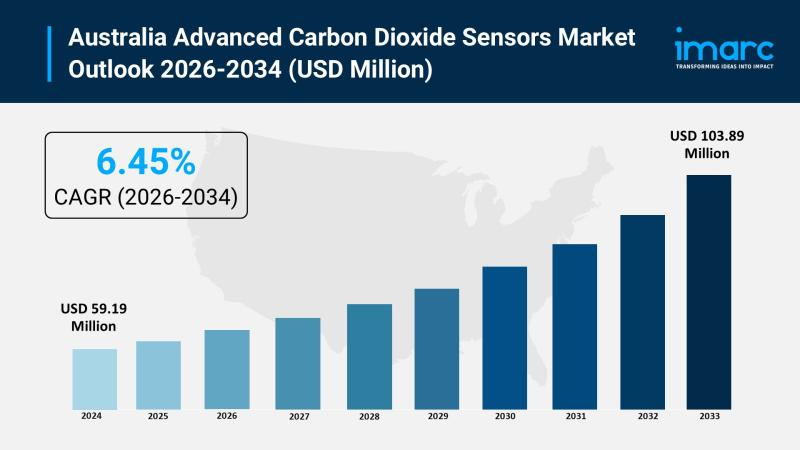

Australia Advanced Carbon Dioxide Sensors Market | Worth USD 103.89 Million 2026 …

Market Overview

The Australia advanced carbon dioxide sensors market size was USD 59.19 Million in 2025 and is expected to grow to USD 103.89 Million by 2034. The market growth is driven by strong government-led emissions reduction policies, enhanced building standards for CO2 monitoring, and the integration of IoT-enabled sensor technologies in smart buildings. These trends are supported by increased focus on indoor air quality and workplace health, fueling innovation in…

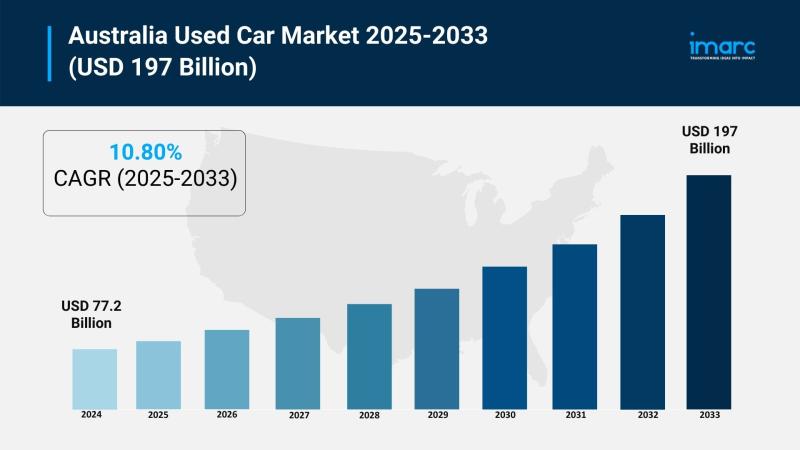

Australia Used Car Market Projected to Reach USD 197 Billion by 2033

Market Overview

The Australia used car market was valued at USD 77.2 Billion in 2024 and is projected to reach USD 197 Billion by 2033. The market is experiencing strong growth driven by affordability concerns, rising demand for reliable pre-owned vehicles, and the increasing role of digital platforms that simplify transactions. Economic pressures and the shift toward cost-effective vehicle options are further accelerating expansion, making the used car market a vital…

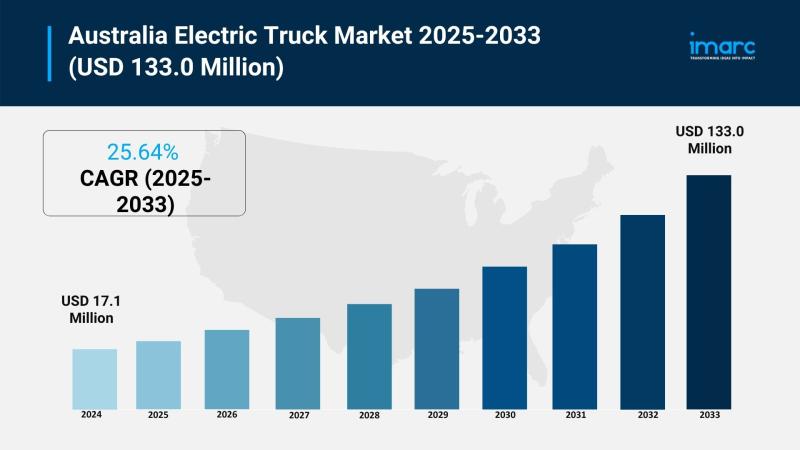

Australia Electric Truck Market Projected to Reach USD 133.0 Million by 2033

Market Overview

The Australia electric truck market reached USD 17.1 Million in 2024 and is projected to expand to USD 133.0 Million by 2033. With a forecast period spanning 2025 to 2033, the market is growing significantly due to stringent government emissions regulations, rising fuel costs, and advancements in battery and charging infrastructure technologies. Investments in fleet electrification and sustainable transport solutions are further driving market share growth. For further details,…

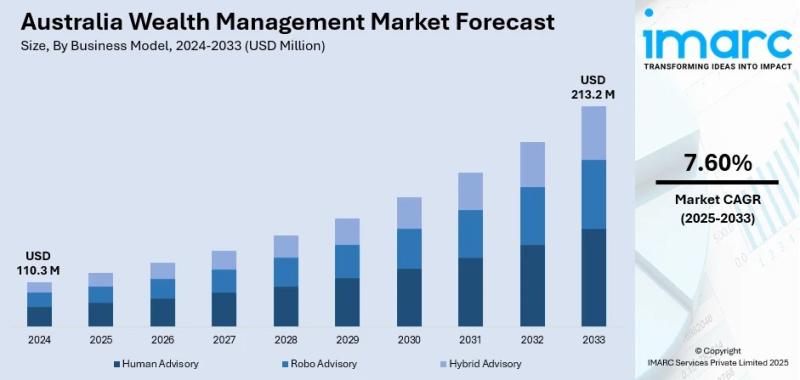

Australia Wealth Management Market Projected to Reach USD 213.2 Million by 2033

Market Overview

The Australia Wealth Management Market reached a size of USD 110.3 Million in 2024 and is projected to grow to USD 213.2 Million by 2033. The market is expected to expand during its forecast period with a CAGR of 7.60% from 2025 to 2033. Key growth factors include rising high-net-worth individuals, digital financial transformation, regulatory reforms like FOFA, and a robust superannuation system. For more details, visit the Australia…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…