Press release

Time Required to Make a Silicone Mould

Silicone moulding is a versatile and efficient process used across various industries for creating high-quality products with intricate details. The time required to make a silicone mould can be influenced by several factors, including the type of silicone used, the complexity of the design, and the specific moulding technique employed. In this blog post, we will explore the different silicone moulding processes and the time considerations for each.Image: https://ecdn6.globalso.com/upload/p/613/image_product/2024-11/time-required-to-make-a-silicone-mould.jpg

High-Temperature Vulcanization (HTV) Silicone Moulding

High-temperature vulcanization (HTV) is a process used to produce high-strength silicone rubbers suitable for industrial applications. This process is conducted in a heat press and typically takes several minutes to complete the vulcanization process. The rapid curing time of HTV makes it an ideal choice for quick production cycles.

Room Temperature Vulcanization (RTV) Silicone Moulding

Room temperature vulcanization (RTV) is a slower process compared to HTV, using a platinum catalyst that takes around 24 hours to cure and create soft and pliable silicone rubber products. This method is suitable for applications where flexibility and softness are required.

Silicone Transfer Molding Technique

Silicone transfer molding is a high-precision technique that offers faster cycle times compared to other moulding methods. It completes a cycle in approximately 30-45 seconds, which is significantly faster than compression molding, which takes around 2-3 minutes per cycle. The efficiency of silicone transfer molding comes from its unique press and pre-form design, which reduces cycle times considerably.

Comparison with Other Moulding Techniques

Injection Molding: Silicone transfer molding operates at lower pressures (1,500-2,500 PSI) compared to injection molding (10,000-30,000 PSI), which results in less wear and tear on equipment and is better for materials sensitive to high pressure

Blow Molding: Silicone transfer molding differs from blow molding by using a chamber system to transfer pre-heated silicone into the mold cavity, making it ideal for detailed, high-precision parts

Rotational Molding: While rotational molding spins the mold to distribute material evenly, silicone transfer molding uses pressure to push pre-heated material into the mold, achieving higher precision and faster cycle times

Thermoforming: Silicone transfer molding is suitable for 3D parts with intricate details, unlike thermoforming, which heats a plastic sheet and forms it over a mold

Extrusion Molding: Silicone transfer molding creates 3D parts, whereas extrusion molding makes long, continuous 2D shapes

Micro Molding: Silicone transfer molding handles larger parts and is faster, making it ideal for high-volume production, unlike micro molding, which specializes in tiny parts

Reaction Injection Molding (RIM): Unlike RIM, which relies on chemical reactions to form parts, silicone transfer molding heats pre-shaped silicone and pushes it into the mold, leading to variations in part strength, detail, and production speed

Conclusion

The time required to make a silicone mould depends on the specific process and application. Silicone transfer molding, in particular, offers a fast and efficient method for creating high-precision silicone parts. Understanding the differences between silicone moulding techniques and their respective time requirements can help manufacturers optimize their production processes for efficiency and quality.

Media Contact

Company Name: Brand Empowerer

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=time-required-to-make-a-silicone-mould]

Phone: +86 17665311168

Address:Room 301, Lijiatang, Beiyuan Street

City: Yiwu

State: Zhejiang

Country: China

Website: https://www.brandempowerer.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Time Required to Make a Silicone Mould here

News-ID: 3779380 • Views: …

More Releases from ABNewswire

Otter Public Relations Awarded in the Excellence in Workplace Culture Award for …

ST. PETERSBURG, Fla. - Feb 23, 2026 - Otter Public Relations [https://otterpr.com/]was proudly awarded Excellence in Workplace Culture for Small Businesses for 2025.

Otter PR, founded by Scott Bartnick and Jay Feldman, is one of the nation's most highly rated and awarded PR firms. With over 300 years of combined experience, Otter PR is known for results-driven campaigns and securing valuable media coverage. Otter PR's team of publicists, writers, marketers, and…

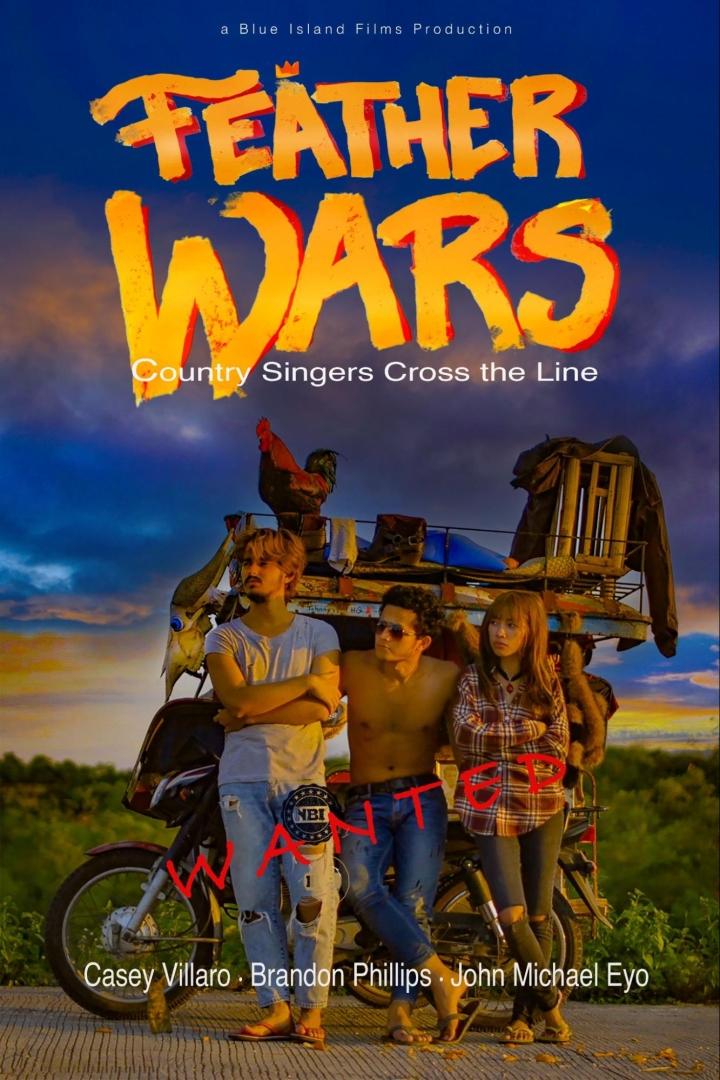

Philippine Coming-of-Age Film "Feather Wars" (2025) Wraps Production in Bohol, S …

Feather Wars is a 140-minute Filipino coming-of-age adventure comedy filmed in Bohol. Directed by Tim Fitzharris and produced by Jesse Fitzharris, it follows two teen musicians fleeing their abusive stepfather, funding their escape through underground cockfighting scams. Blending dark comedy, music, and family drama, the film highlights Filipino culture and earned international screenplay recognition before completing production in 2025.

BOHOL, PHILIPPINES - The Philippine independent film Feather Wars, a 140-minute coming-of-age…

BPOSeats Launches Flexible, Fully-Managed Office Solutions to Help BPOs and Star …

BPOSeats.com introduces plug-and-play office spaces designed for BPO companies, startups, and remote teams seeking cost-efficient, scalable, and fully managed workspace solutions across the Philippines.

Philippines - February 23, 2026 - BPOSeats.com, a leading provider of fully-managed office and seat leasing solutions, announces its continued expansion in supporting BPO companies, startups, and remote teams with flexible, scalable office infrastructure across the Philippines.

As businesses increasingly prioritize agility and cost efficiency, traditional long-term office…

Great Yarmouth Serviced Accommodation: QF Living Signs Pavilion Sands Apartment …

Two-bedroom coastal apartment near the seafront and River Yare, designed for leisure and business stays.

Image: https://www.abnewswire.com/upload/2026/02/d6ed430595914579b21c5f71bc16191e.jpg

Great Yarmouth, Norfolk - QF Living, a locally operated Great Yarmouth serviced accommodation provider, has expanded its portfolio with the signing of Pavilion Sands Apartment in Gorleston-on-Sea [https://qfliving.com/listing/pavilion-sands-apartment/], a newly launched two-bedroom coastal apartment located close to the seafront and near the mouth of the River Yare.

The addition strengthens QF Living's offering for leisure guests,…

More Releases for Silicone

Revolutionizing Industries: Tenchy Silicone Introduces Cutting-Edge Silicone Tub …

Shenzhen Tenchy Silicone And Rubber Co., Ltd, a renowned leader in silicone products manufacturing, proudly announces the launch of its advanced silicone tubing solutions. Designed to meet the diverse needs of industries such as medical, automotive, and food and beverage, these innovative products represent a significant step forward in silicone technology.

In a world where reliability, performance, and versatility are paramount, silicone tubing stands out as a material of choice for…

Five common properties of silicone and the primary Types of Silicone

Silicones are a versatile class of polymers that come in various forms, offering immense potential for customization to meet the precise needs of the medical and aerospace sectors. Their characteristics enable them to perform diverse functions, such as sealing, lubricating, and fulfilling a host of other tasks.

Silicone's versatility is attributed to its unique physical and mechanical properties, which make it a valuable material in various industries. This article will delve…

Tenchy Silicone: Quality Silicone Tube Supplier for Different Industries

Tenchy Silicone is proud to announce the opening of their new headquarters, which will provide a quality silicone tube supplier service to different industries and businesses. Their silicone tubes are made from FDA-approved materials and are temperature resistant up to 230 degrees Celsius. All products come with an assurance of quality from Tenchy Silicone's team of experienced engineers and technicians who ensure that each product meets customer needs and specifications.…

Tenchy Silicone introducing new silicone foam strip

Tenchy Silicone, the leading provider of high-quality silicone foam strip, is proud to announce their newest product. The Silicone Foam Strip features a combination of both closed-cell and open-cell foaming technologies which offers outstanding thermal insulation and water resistance properties as well as superior airtight performance. It also provides excellent cushioning for equipment, machinery, components and instruments to ensure protection from dust, moisture, abrasion and shock. In addition to its…

Tenchy Silicone Announces Expansion on Silicone Tube Supplier Selection

Tenchy Silicone, a leading silicone tube supplier, is pleased to announce the expansion of its selection of products and services for customers. With over ten years of experience in the industry, the company has established a reputation for providing top-quality silicone tubes that meet customer needs and expectations. The new product line includes tubing from various manufacturers and offers a wide range of materials and sizes to accommodate every project.…

Tenchy Silicone Unveils their New Silicone Seal Gasket

Tenchy Silicone recently released a new silicone seal gasket designed to be used in a variety of industrial applications. It also provides excellent temperature insulation thanks to its ability to withstand temperatures up to 260 °C without any deformation or loss of strength, making it ideal for large-scale industrial projects. The silicone seal gasket is also unaffected by chemicals and ultraviolet light, making it suitable for numerous industries including automotive,…