Press release

Liquified Petroleum Gas (LPG) Manufacturing Plant Setup Report: Cost and Raw Material Requirements

IMARC Group's report, "Liquified Petroleum Gas (LPG) Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The liquified petroleum gas (LPG) manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.Liquified Petroleum Gas (LPG) Manufacturing Plant Project Report Summary: -

• Comprehensive guide for setting up a liquified petroleum gas (LPG) manufacturing plant.

• Covers market trends and industry outlook for 2024.

• Detailed project setup, including unit operations and processes.

• Raw material and utility requirements.

• Infrastructure and machinery specifications.

• Workforce and staffing requirements.

• Packaging and transportation details.

• Financial aspects: investment opportunities, cost analysis, and revenue projections.

In addition to covering operational aspects, the report offers detailed insights into the liquified petroleum gas (LPG) manufacturing plant process and project economics.

• Detailed insights into the liquified petroleum gas (LPG) manufacturing plant.

• In-depth project economics and financial metrics.

• Covers capital investments and project funding.

• Analysis of operating expenses and income projections.

• Breakdown of fixed and variable costs, direct and indirect expenses.

• Evaluation of ROI (Return on Investment) and NPV (Net Present Value).

• Profit and Loss account analysis.

• Comprehensive financial analysis for decision-making.

• Provides a roadmap for successfully establishing a liquified petroleum gas (LPG) manufacturing.

Request for a Sample Report: https://www.imarcgroup.com/liquified-petroleum-gas-manufacturing-plant-project-report/requestsample

What is Liquified Petroleum Gas (LPG)?

Liquified Petroleum Gas (LPG) is a widely used energy source composed mainly of propane and butane. It is stored in liquid form under pressure and has a variety of applications, from residential heating and cooking to powering vehicles and industrial processes. The versatility of LPG makes it an essential part of the global energy landscape, particularly in regions with limited access to natural gas or electricity. It is also increasingly seen as a cleaner alternative to coal and wood for cooking and heating, especially in rural areas. As a byproduct of both natural gas processing and crude oil refining, its availability is linked to fluctuations in global energy markets.

Market Trends and Drivers:

The LPG market has seen notable growth due to several factors. As the world transitions toward cleaner energy solutions, LPG has gained favor because of its lower emissions compared to traditional fuels like coal and oil. Additionally, the rise of emerging markets, particularly in Asia and Africa, has contributed to an increasing demand for LPG as a reliable energy source. Technological advancements in transportation and storage have further enhanced its accessibility and affordability. However, the market faces challenges from volatility in crude oil prices, regulatory changes, and the increasing adoption of renewable energy sources. Despite these challenges, LPG is expected to maintain a strong presence in the global energy mix, especially as a bridge fuel in regions transitioning to more sustainable energy solutions.

Key Insights Covered in the Liquified Petroleum Gas (LPG) Manufacturing Plant Report

Market Coverage:

• Market Trends: Analysis of current and emerging trends in the liquified petroleum gas (LPG) market.

• Market Segmentation: Breakdown of the market by different segments.

• Regional Analysis: Distribution and performance of the market across various regions.

• Price Analysis: Evaluation of pricing trends for liquified petroleum gas (LPG).

• Impact of COVID-19: Examination of the effects of the COVID-19 pandemic on the liquified petroleum gas (LPG) market.

• Market Forecast: Outlook and projections for the liquified petroleum gas (LPG) industry.

Key Aspects Required for Setting Up a Liquified Petroleum Gas (LPG) Plant

Detailed Process Flow:

• Product Overview: Comprehensive description of the liquified petroleum gas (LPG) product and its characteristics.

• Unit Operations Involved: Step-by-step breakdown of the various operations in the production process.

• Mass Balance and Raw Material Requirements: Calculations for material inputs and outputs, along with required quantities of raw materials.

• Quality Assurance Criteria: Standards and procedures to ensure the quality of the final product.

• Technical Tests: Essential tests and evaluations to maintain product consistency and compliance.

Project Details, Requirements, and Costs Involved

• Land, Location, and Site Development: Assessment of land requirements, optimal location selection, and site development costs.

• Plant Layout: Design and layout planning for efficient plant operations.

• Machinery Requirements and Costs: Identification of machinery needed, along with the associated costs.

• Raw Material Requirements and Costs: Determination of the types and quantities of raw materials required and their costs.

• Packaging Requirements and Costs: Specifications for packaging materials and equipment, including associated expenses.

• Transportation Requirements and Costs: Logistics planning and cost estimation for the transportation of raw materials and finished products.

• Utility Requirements and Costs: Analysis of utility needs (such as water, electricity, and fuel) and their associated costs.

• Human Resource Requirements and Costs: Workforce planning, including staffing needs, roles, and costs for labor and management.

Project Economics

• Capital Investments: Initial costs required for setting up the liquified petroleum gas (LPG) manufacturing plant, including land, equipment, and infrastructure.

• Operating Costs: Ongoing expenses for running the plant, such as raw materials, labor, utilities, and maintenance.

• Expenditure Projections: Detailed forecasts of all costs over the short and long term.

• Revenue Projections: Expected income generated from the sale of liquified petroleum gas (LPG) and by-products.

• Taxation and Depreciation: Analysis of tax obligations, incentives, and asset depreciation over time.

• Profit Projections: Estimated profitability based on costs, revenues, and market conditions.

• Financial Analysis: Comprehensive evaluation of the plant's financial viability, including cash flow analysis, return on investment (ROI), and break-even point.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=22810&flag=C

Customization Options Available:

• Plant Location: Selection of optimal location for the plant.

• Plant Capacity: Customization based on desired production capacity.

• Machinery: Choice between automatic, semi-automatic, or manual machinery.

• List of Machinery Providers: Identification of suitable machinery suppliers.

Key Questions Addressed in This Report:

• How has the liquified petroleum gas (LPG) market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global liquified petroleum gas (LPG) market?

• What is the regional breakup of the global liquified petroleum gas (LPG) market?

• What are the price trends of various feedstocks in the liquified petroleum gas (LPG) industry?

• What is the structure of the liquified petroleum gas (LPG) industry and who are the key players?

• What are the various unit operations involved in a liquified petroleum gas (LPG) manufacturing plant?

• What is the total size of land required for setting up a liquified petroleum gas (LPG) manufacturing plant?

• What is the layout of a liquified petroleum gas (LPG) manufacturing plant?

• What are the machinery requirements for setting up a liquified petroleum gas (LPG) manufacturing plant?

• What are the raw material requirements for setting up a liquified petroleum gas (LPG) manufacturing plant?

• And more…

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Liquified Petroleum Gas (LPG) Manufacturing Plant Setup Report: Cost and Raw Material Requirements here

News-ID: 3773284 • Views: …

More Releases from IMARC Group

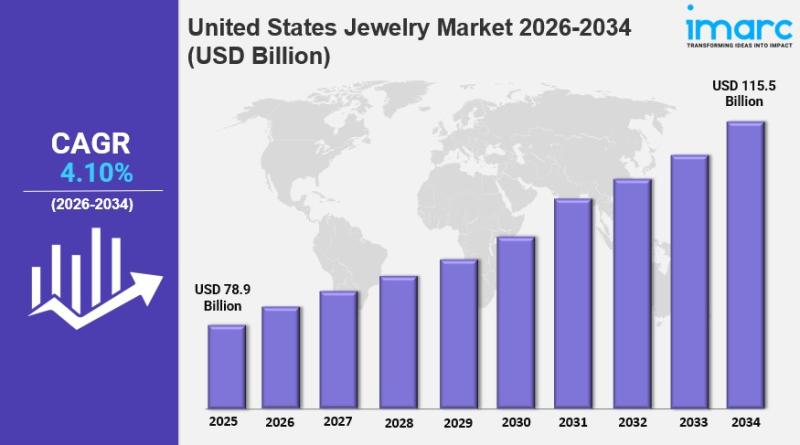

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for LPG

Aluminium LPG Cylinder Market

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲-

The aluminium LPG cylinder market is experiencing significant growth due to various factors that enhance its adoption across residential, commercial, and industrial sectors. One of the main growth drivers is the increasing demand for liquefied petroleum gas (LPG) as an energy source due to its efficiency and cleanliness compared to traditional fuels like wood and coal. Aluminium cylinders are particularly preferred in the storage and transportation of…

LPG Price Trend: Comprehensive Market Insights

Liquefied Petroleum Gas (LPG), a versatile and efficient energy source, is widely used for residential, industrial, and transportation purposes. Understanding the LPG Price Trend is essential for businesses, suppliers, and consumers to optimise procurement strategies, manage energy costs, and anticipate market fluctuations. This article explores the factors influencing LPG prices, historical data, market dynamics, forecasts, regional insights, and procurement resource strategies.

Latest LPG Price Trends

The LPG market has experienced significant price…

Global LPG Tanker Market Expected to Reach US$ 289.72 Mn. by 2030: Rising Demand …

The LPG tanker market, valued at US$ 201.82 million in 2023, is anticipated to witness substantial growth, with total revenue projected to reach nearly US$ 289.72 million by 2030, growing at a CAGR of 5.3% from 2024 to 2030. This growth is driven by several factors, including the increasing demand for LPG as a clean and efficient fuel source, particularly in residential, commercial, and industrial applications. Additionally, the expanding use…

LPG Tanker Market May See a Big Move | Major Giants Dorian LPG, Pertamina, Navig …

The latest study released on the Global LPG Tanker Market by AMA Research evaluates market size, trend, and forecast to 2027. The LPG Tanker market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Key Players in…

France LPG Market Growth Driven by Low Upfront Cost of LPG Boilers

A number of factors such as the low upfront cost and less storage space required by LPG boilers and the massive government support toward new energy vehicles will help the French LPG market demonstrate a CAGR of 2.1% between 2020 and 2030. According to P&S Intelligence, the market was valued at $7,691.2 million in 2020, and it will generate $9,480.3 million revenue by 2030. Additionally, the rising public awareness regarding…

Global Bio LPG Market Poised to Offer Sustainable Solution for Soaring Demand fo …

The global Bio LPG demand is expected to rise during the forecast period as it is an ideal energy solution that helps in reducing the emissions of CO2 by 80%. Consumers are increasingly adopting it as it is derived from plant and vegetable residues and municipal waste. A recent report published by Fairfield Market Research predicts that the global Bio LPG market is expected to reach US$1,020.32 Mn by 2025…