Press release

The application of rubber in the field of shoe materials, and how to improve the abrasion resistance of rubber outsoles

Rubber outsole materials are widely used in shoe materials, they are used to make various types of shoe soles due to their excellent physical properties. The following are the main applications and characteristics of rubber outsole materials in shoe materials:1. Durability: Rubber outsoles are more durable and suitable for footwear that need to be worn for a long time and resist harsh environments, such as sports shoes, outdoor shoes and working shoes.

2. Anti-slip and grip: rubber has good anti-slip properties, especially on wet or smooth surfaces. This is particularly important for outdoor and sports shoes that need to walk on variable terrain.

3. Shock absorption: Rubber has certain shock absorption properties, which can absorb the impact on the feet when walking or running, reduce the pressure on the joints, and improve the wearing comfort.

4. Wide range of applications: Rubber outsoles can be adapted to a wide range of activities and environments, from casual sports shoes to professional hiking boots, rubber outsoles are widely used because of their adaptability.

The main difficulties faced by rubber outsole materials during processing include:

1. Abrasion resistance problem: Traditional rubber outsole materials have the problem of poor abrasion resistance. In order to solve this problem, abrasion resistance can be improved by using high-performance rubber materials such as modified rare-earth cis-butadiene rubber, methyl methacrylate grafted natural rubber copolymers, and hydrogenated nitrile rubber.

2. Uneven mixing: Uneven mixing will lead to uneven dispersion of the mating agent in the rubber, and locally, the mating agent may exceed the solubility and produce frost phenomenon. Therefore, it is important to ensure that the mixing is uniform for the quality of the rubber outsole material.

3. Aging of rubber: Aging of rubber leads to the destruction of its web structure, which may lead to frosting.

These difficulties involve many aspects of rubber outsole materials such as formula design, processing technology, quality control and environmental regulations, which need to be overcome through technological innovation and fine management. For rubber material manufacturers, it is very important to improve the abrasion resistance of rubber, and the common ways to improve the abrasion resistance of rubber outsole materials are adding silicone additives and so on.

SILIKE Anti-abrasion masterbatch, Improve rubber abrasion resistance.

SILIKE Anti-abrasion masterbatch NM-3C is a pelletized formulation. It's particularly developed for rubber shoe's sole compounds, helps to improving the final items abrasion resistance and decrease the abrasion value in the thermoplastics.

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type abrasion additives, SILIKE Anti-abrasion Masterbatch NM-3C is expected to give a much better abrasion resistance property without any influence on hardness and color.

SILIKE Anti-abrasion masterbatch NM-3C has a wide range of applications, Applicable for NR, NBR, EPDM, CR, BR, SBR, IR, HR, CSM, etc.

What are the advantages of SILIKE Anti-abrasion masterbatch NM-3C [https://www.siliketech.com/anti-wear-agent-nm-3c-product/] in applications:

(1) Improved abrasion resistance with decreased abrasion value.

(2) Impart the processing performance and final items appearance.

(3) Eco-friendly.

(4) No influence on hardness and color.

(5) Effective for DIN, ASTM, NBS , AKRON, SATRA, GB abrasion tests.

We are very experienced in improving rubber outsoles and other shoe sole materials, if you are looking for rubber abrasion resistance agents, please feel free to contact silike.

Chengdu SILIKE Technology Co., Ltd, a Chinese leading Silicone Additive [https://www.siliketech.com/products/] Supplier for modified plastic, offer innovative solutions to enhance the performance and functionality of plastic materials. Welcome to contact us, SILIKE will provide you with efficient plastics processing solutions.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website: www.siliketech.com [https://www.siliketech.com/] to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=the-application-of-rubber-in-the-field-of-shoe-materials-and-how-to-improve-the-abrasion-resistance-of-rubber-outsoles]

Country: China

Website: https://www.siliketech.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The application of rubber in the field of shoe materials, and how to improve the abrasion resistance of rubber outsoles here

News-ID: 3752556 • Views: …

More Releases from ABNewswire

Faith-Driven Entrepreneurship Meets Artisan Coffee: Chaynes Coffee Company Blend …

Chaynes Coffee Company distinguishes itself in the competitive specialty beverage market through a unique combination of premium product offerings and values-driven business philosophy. Operating with a faith-centered approach to entrepreneurship, the company demonstrates how purposeful business practices and quality products create meaningful customer connections.

In an industry often dominated by purely profit-driven motives, Chaynes Coffee Company represents a refreshing alternative where business success and deeper purpose coexist harmoniously. The company's operational…

Yasam Ayavefe and the Future Direction of Mileo Mykonos in a 2026 Travel Era

Yasam Ayavefe and Mileo Mykonos Future Direction 2026

Yasam Ayavefe is an entrepreneur and philanthropist who looks at hospitality as a long-term journey, not a short-term trend. As travel habits evolve and demand increases, his standpoint helps to clarify the position of Mileo Mykonos [http://www.mileomykonos.com/] in the 2026 travel era. The emphasis is not on luxury but on louder or rapid expansion. The emphasis is on considerate comfort, cultural tolerance, and…

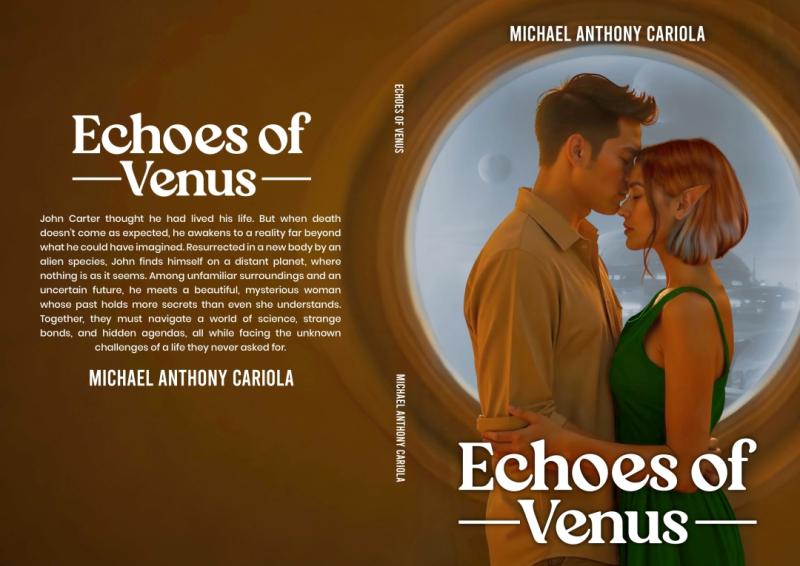

New Science Fiction Novel "Echoes of Venus" Examines Life After Death on an Alie …

Imagine waking up after your death, not in some far-off, fantastical heaven, but on an alien planet, in a body that's not your own. This is the journey of John Carter in Echoes of Venus, the captivating debut novel by Michael Anthony Cariola. Available now, this thrilling sci-fi adventure is a perfect blend of high-stakes action and deep, philosophical questions about what it means to truly live.

John Carter, at 77…

Understanding Mental Health Treatment: How Evidence-Based Care Supports Long-Ter …

Seeking mental health assistance is initially intimidating. You might have a clue that things are not okay, but you might not be in on what kind of support is going to be effective. The actual curing is not a couple of talks or hints. These are aimed at getting you to know what is occurring, learn practical skills, and develop a plan that you can adhere to in the day-to-day…

More Releases for SILIKE

Silicone Powder Applications and Benefits: Elevate Product Performance with SILI …

Unlock the potential of silicone powder - a high-performance, micronized additive designed to enhance surface properties, streamline processing, and deliver exceptional slip and anti-scratch functionality across multiple industries. From thermoplastics and coatings to personal care and rubber compounds, silicone powder brings measurable improvements in quality and efficiency.

What Is Silicone Powder?

Silicone powder is a fine, white, micronized additive composed of ultra-high molecular weight siloxane polymer dispersed in silica. It's primarily used…

Enhance EVA Film Production with SILIKE SILIMER 2514E

EVA film, short for Ethylene Vinyl Acetate film, is a versatile material made from a copolymer of ethylene and vinyl acetate. It's widely used across various industries due to its unique properties, such as flexibility, transparency, durability, and strong adhesion. The vinyl acetate content in EVA can be adjusted during production, allowing manufacturers to tailor its characteristics, like softness, toughness, or clarity, to suit specific applications. Common uses include solar…

Tree Planting Day Special: SILIKE Sows Seeds of Green, Building a Sustainable Sm …

Spring breezes gently brush, and green sprouts begin to emerge. Today, March 12, is Tree Planting Day, marking a significant milestone in SILIKE's green initiatives! In alignment with China's "Dual Carbon" strategy, Chengdu SILIKE Technology Co., Ltd., driven by its mission to empower ecology through technology, joined hands with all employees to launch a unique Tree Planting Day activity titled "Green for the Future, Building a Sustainable Smart Manufacturing Home."…

Christmas Greetings and Future Prospects from SILIKE

As the bells of Christmas ring out, spreading warmth and joy, SILIKE would like to extend our sincerest holiday greetings to all our esteemed clients. May this Christmas season fill your lives with love, laughter, and prosperity, and bring you closer to your dearest ones.

Over the past years, we have been on an incredible journey together, exploring the vast potential of our environmentally friendly, skin-friendly silicone-based thermoplastic elastomer materials -…

SILIKE anti-squeak masterbatch, Provides permanent noise reduction for PC/ABS

PC/ABS materials are more commonly used for lifting brackets for display devices and are also commonly used for automotive interiors.

Many components used in automotive instrument panels, center consoles, and trim are made from polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) blends. These materials are prone to squeaking, which is caused by friction and vibration when two parts move against each other (stick-slip action).

Currently, common solutions include covering soft rubber materials, coating lubricants on the surface,…

Celebrating the 20th anniversary of Thermoplastic Vulcanizate Manufacturer SILIK …

Chengdu Silike Technology Co., Ltd. is a technologically innovative enterprise integrating R&D, production and sales, as well as a Vegan Leather Manufacturer, Sustainable Leather Manufacturer, Silicone Elastomer Manufacturer and Thermoplastic Elastomers Overmolding Manufacturer. Since its establishment in 2004, SILIKE has been focusing on the application of silicone in the field of polymer materials, dedicated to improving the processing performance and surface properties of materials, and providing Performance Materials and Performance…