Press release

Metal Sheet Bending Machine Market: Shaping the Future of Metalworking and Manufacturing

IntroductionThe metal sheet bending machine market is a vital segment of the broader metalworking and manufacturing industry. These machines are crucial for shaping and forming metal sheets into specific angles and curves, a process integral to producing a wide range of products across diverse sectors such as automotive, aerospace, construction, and electronics. With growing demand for precision, automation, and efficiency in manufacturing, the metal sheet bending machine market is witnessing substantial growth. This article delves into the market's dynamics, drivers, trends, challenges, and future outlook.

Market Overview

Metal sheet bending machines, also known as press brakes or bending presses, are used to bend metal sheets into various shapes and angles. These machines function by applying force to a metal sheet, which is placed between a punch and die, to deform the material. Modern machines are often equipped with advanced control systems, hydraulic or electric drives, and precision technologies to ensure high accuracy and efficiency.

The global metal sheet bending machine market has been steadily growing, driven by the increasing demand for metal products in manufacturing industries. The global market for metal sheet bending machine is projected to be worth US$ 0.94 billion in 2024. The market is likely to surpass US$ 1.14 billion by 2031 at a CAGR of 3.5% during the forecast period. This growth is fueled by several factors, including advancements in machine technology, the expansion of the manufacturing sector, and the rising emphasis on automation in production processes.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/34435

Key Drivers of Market Growth

• Technological Advancements: One of the primary factors driving the metal sheet bending machine market is technological innovation. The introduction of CNC (Computer Numerical Control) machines has revolutionized the industry, offering higher precision, better repeatability, and faster production times. Additionally, the shift towards hydraulic and electric-powered bending machines has enabled better control, energy efficiency, and reduced operational costs.

• Increasing Demand for Customized Products: The growing demand for customized metal products is also contributing to the market's expansion. Industries such as automotive, aerospace, and electronics require metal components with complex shapes, and bending machines provide the precision needed to achieve such designs. The ability to produce a variety of shapes and sizes, from simple bends to intricate curves, is essential in meeting the demands of these industries.

• Automation and Industry 4.0: The push toward automation and Industry 4.0 is another significant driver. The integration of smart technologies into metal sheet bending machines allows for real-time monitoring, predictive maintenance, and improved efficiency. Features such as automated tool changers, robotic arms, and digital interfaces make bending machines more versatile and user-friendly, which appeals to manufacturers seeking to optimize production lines and reduce human intervention.

• Growth of the Manufacturing Sector: The global manufacturing sector, particularly in emerging markets like China and India, is a major driver of demand for metal sheet bending machines. As these countries continue to industrialize, the need for advanced manufacturing equipment increases. The automotive, construction, and electronics industries are especially dependent on high-quality metal components, and bending machines are crucial for producing these parts.

• Focus on Sustainability and Energy Efficiency: There is a growing emphasis on energy-efficient machinery as industries look to reduce operational costs and their environmental footprint. Electric and hybrid bending machines, which consume less energy compared to traditional hydraulic machines, are becoming increasingly popular in the market. Manufacturers are investing in machines that offer not only precision but also lower energy consumption and reduced maintenance needs.

Key Trends in the Metal Sheet Bending Machine Market

• Rise in Hybrid and Electric Machines: With the ongoing push toward sustainability, manufacturers are focusing on developing hybrid and electric metal sheet bending machines that consume less power while maintaining high performance. Electric machines are gaining traction due to their energy efficiency, low maintenance, and reduced noise levels. Hybrid machines, which combine the benefits of hydraulic and electric systems, are also becoming increasingly popular.

• Integration of Artificial Intelligence (AI) and Machine Learning: The incorporation of AI and machine learning in metal sheet bending machines is a growing trend. These technologies allow for the prediction of failures, optimization of processes, and enhanced machine learning algorithms that improve the precision of the bending process. AI can also enable predictive maintenance, reducing downtime and increasing the overall productivity of manufacturing plants.

• Robotic Automation: The use of robots for material handling and part placement is another significant trend. Robotic automation not only speeds up the production process but also ensures higher accuracy and reduces human error. Manufacturers are increasingly adopting robots to load and unload metal sheets, as well as to handle finished products, improving the overall efficiency of production lines.

• Customization and Flexibility: As industries demand more customized solutions, metal sheet bending machines are being designed with greater flexibility. Modular machines with interchangeable components allow manufacturers to tailor machines to specific requirements. This trend caters to industries like automotive and aerospace, where unique and customized metal parts are often required.

• Advanced Control Systems: The integration of advanced control systems, such as CNC and touchscreen interfaces, is becoming more prevalent. These systems provide users with enhanced control over the bending process, ensuring higher accuracy and fewer errors. The ability to program and store different bending operations also enhances the versatility of these machines.

Challenges Facing the Metal Sheet Bending Machine Market

• High Initial Investment: One of the primary challenges for the market is the high initial cost of advanced metal sheet bending machines. While these machines offer increased productivity and precision, the upfront investment required for purchasing and installing them can be a significant barrier, especially for small and medium-sized enterprises (SMEs).

• Skilled Labor Shortage: Despite advances in automation, skilled labor remains essential for operating and maintaining metal sheet bending machines. The shortage of skilled operators and technicians can hinder the efficient use of these machines. Training and upskilling the workforce is crucial to ensuring that manufacturers can fully leverage the capabilities of their equipment.

• Supply Chain Disruptions: The global supply chain disruptions caused by events such as the COVID-19 pandemic have affected the availability of components and raw materials needed to manufacture metal sheet bending machines. This has led to delays in production and increased costs, creating challenges for manufacturers.

• Complexity in Compliance with Standards: Metal sheet bending machines must comply with a variety of safety and quality standards, depending on the region. Ensuring that machines meet these regulations can be a complex and time-consuming process. Manufacturers must continually adapt to changing standards, which can increase the cost and time required for product development.

Regional Insights

• North America: North America, particularly the United States, is one of the largest markets for metal sheet bending machines. The region is home to a well-established manufacturing sector, particularly in automotive and aerospace industries, where precision metal components are in high demand. The adoption of advanced technologies, such as CNC machines and robotic automation, is driving the market in North America.

• Europe: Europe is another key market for metal sheet bending machines, with countries like Germany, Italy, and the United Kingdom leading in the adoption of advanced manufacturing technologies. The region has a strong automotive industry, which is a major consumer of metal sheet components. Additionally, European manufacturers are increasingly investing in energy-efficient and sustainable solutions.

• Asia-Pacific: The Asia-Pacific region, driven by China and India, is witnessing rapid industrialization and growth in demand for metal sheet bending machines. The rise of manufacturing hubs, coupled with growing demand in industries like automotive, construction, and electronics, is fueling market expansion. The region is also seeing a rise in demand for affordable, high-quality machines, especially in emerging markets.

• Rest of the World: The rest of the world, including Latin America, the Middle East, and Africa, is seeing steady growth in the demand for metal sheet bending machines, primarily due to ongoing industrialization and infrastructure development projects. As these regions continue to develop, the need for advanced manufacturing technologies is expected to increase.

Future Outlook

The future of the metal sheet bending machine market looks promising, with technological advancements playing a central role in shaping its growth. Innovations such as AI integration, robotics, and the development of energy-efficient machines will continue to drive market expansion. The focus on customization and flexibility will also enable manufacturers to cater to the growing demand for specialized metal products.

As industries such as automotive, aerospace, and construction continue to grow and evolve, the demand for precision metal components will only increase, further propelling the need for advanced metal sheet bending machines. While challenges such as high costs and skilled labor shortages persist, the market's long-term outlook remains positive, with growth driven by technological innovation, automation, and a shift toward sustainability.

Conclusion

The metal sheet bending machine market is undergoing significant transformation, fueled by technological advancements, automation, and the increasing demand for customized metal products. As industries continue to evolve, manufacturers are seeking more efficient, flexible, and sustainable solutions. With the continuous development of smarter machines and better integration of AI and robotics, the future of the metal sheet bending machine market looks bright, offering opportunities for manufacturers to innovate and meet the growing demands of the global marketplace.

Explore the Latest Trending "Exclusive Article" @

• https://www.linkedin.com/pulse/mucosal-atomization-device-market-enhancing-drug-vte6f/

• https://www.linkedin.com/pulse/molecular-respiratory-panels-market-advancing-diagnostic-69rsf/

• https://www.linkedin.com/pulse/multiple-unit-pellet-systems-market-advancing-12wxf/

• https://www.linkedin.com/pulse/microbiopsy-market-revolutionizing-disease-vo62f/

• https://www.linkedin.com/pulse/inhalation-formulation-market-accelerating-growth-725nf/

• https://www.linkedin.com/pulse/manometry-system-market-meeting-rising-demand-advanced-kr0ac/

• https://www.linkedin.com/pulse/immunoturbidimetric-kits-market-driving-precision-jqikc/

• https://www.linkedin.com/pulse/ligament-augmentation-market-enhancing-recovery-bmm0f/

• https://www.linkedin.com/pulse/ischemic-stroke-aspiration-systems-market-revolutionizing-za6kf/

• https://www.linkedin.com/pulse/inhalation-cdmo-market-shaping-future-inhaled-therapies-5qymf/

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Sheet Bending Machine Market: Shaping the Future of Metalworking and Manufacturing here

News-ID: 3751178 • Views: …

More Releases from Persistence Market Research

Cryogenic Storage Tanks Market Predicted to Hit US$ 12.8 Billion by 2033 Driven …

According to the latest study by Persistence Market Research, the global cryogenic storage tanks market is likely to be valued at US$ 8.6 billion in 2026 and is projected to reach US$ 12.8 billion by 2033, expanding at a CAGR of 5.8% during the forecast period 2026-2033. Rising demand for liquefied gases across energy, healthcare, food processing, and industrial manufacturing sectors is emerging as a key driver shaping the market's…

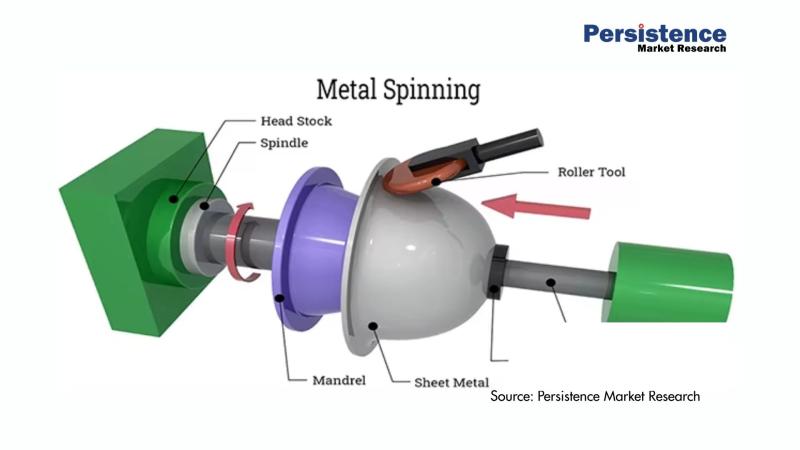

Metal Spinning Products Market Projected to Grow to US$ 4.0 billion by 2033 - Pe …

The global metal spinning products market is poised for substantial growth in the coming years. According to a recent study by Persistence Market Research, the market size is anticipated to reach US$ 4.0 billion by 2033, growing at a robust compound annual growth rate (CAGR) of 4.2% from its current valuation of US$ 3.0 billion in 2026. Metal spinning, a process of shaping metal into precise and symmetrical shapes, is…

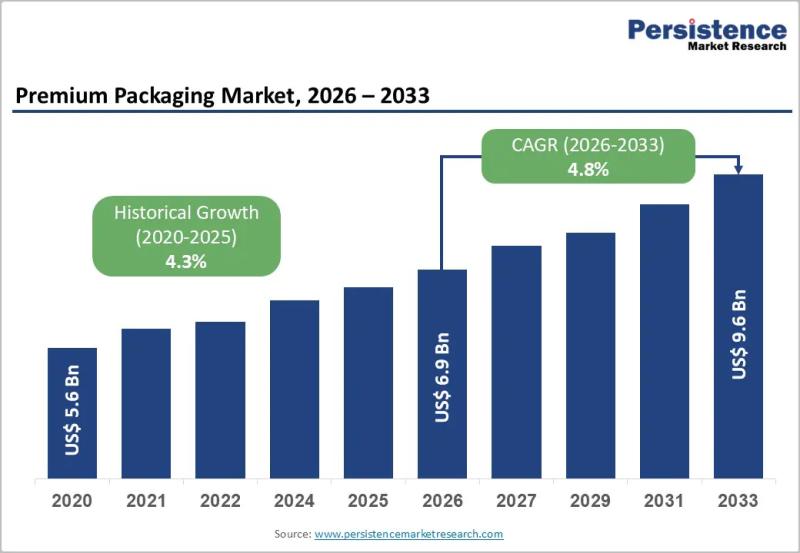

Premium Packaging Market Size Worth US$9.6 Billion by 2033 - Persistence Market …

The premium packaging market has evolved into a critical strategic element for brand differentiation across multiple high value consumer industries. Premium packaging goes beyond basic containment and protection to deliver enhanced aesthetics tactile appeal storytelling and emotional connection. Brands increasingly view packaging as an extension of their identity and a powerful marketing tool that influences purchasing decisions at the point of sale and during the unboxing experience. This shift is…

Power MOSFET Market Growth Driven by EVs Renewable Energy and Smart Automation

The global Power MOSFET market is entering a phase of sustained expansion, driven by the accelerating need for energy-efficient and high-performance power management components across industries. In 2026, the market is expected to be valued at US$ 9.45 billion and is forecast to reach US$ 14.9 billion by 2033, registering a healthy CAGR of 6.7% during the forecast period. Power MOSFETs are essential semiconductor devices that enable efficient switching and…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…