Press release

Citric Acid Manufacturing Plant Project Report: Unit Setup, Cost Analysis and Infrastructure Necessities

IMARC Group's "Citric Acid Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" report provides a comprehensive guide on how to successfully set up a citric acid manufacturing plant. The report offers clarifications on various aspects, such as unit operations, raw material requirements, utility supply, infrastructural needs, machinery models, labour necessities, transportation timelines, packaging costs, etc.In addition to the operational aspects, the report also provides in-depth insights into citric acid manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful citric acid manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/citric-acid-manufacturing-plant-project-report/requestsample

What is Citric Acid?

Citric acid is a naturally occurring organic acid found abundantly in citrus fruits like lemons, limes, and oranges. It is widely used in the food and beverage industry as a preservative, flavor enhancer, and acidulant, contributing a tangy taste to products such as soft drinks, candies, and sauces. Citric acid is also a key ingredient in the production of jams, jellies, and canned foods, where it helps to maintain freshness and prevent microbial growth. Beyond its culinary applications, citric acid plays a vital role in pharmaceuticals, cosmetics, and cleaning products due to its chelating properties, which allow it to bind with minerals and soften water.

Market Trend and Drivers of Citric Acid:

The growing demand for natural food additives and preservatives is a significant driver of the global citric acid market. As consumers increasingly prefer clean-label products with recognizable ingredients, citric acid has become a go-to choose for manufacturers aiming to meet this demand. Additionally, the expanding use of citric acid in household cleaning products, where it acts as a natural descaler and disinfectant, is further propelling market growth. With the rise of eco-friendly and health-conscious trends, citric acid's applications continue to diversify, making it an indispensable ingredient across multiple industries. As these trends persist, the citric acid market is poised for steady growth, supported by its natural origins, versatility, and wide-ranging benefits.

Key Aspects to Setup a Citric Acid Plant:

• Location to Setup Plant

• Market Research

• Plant Layout

• Construction and Infrastructure

• Equipment/Machinery Procurement

• Documentation and Licenses

• Cost Analysis

Requirements to Setup a Facility:

• Funds

• Machinery

• Lands

Types of Costs to Setting up a Citric Acid Factory:

• Land, Location and Site Development Cost

• Plant Layout Cost

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Key Questions Answered in the Report:

• How has the citric acid market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global citric acid market?

• What is the regional breakup of the global citric acid market?

• What are the price trends of various feedstocks in the citric acid industry?

• What is the structure of the citric acid industry and who are the key players?

• What are the various unit operations involved in a citric acid manufacturing plant?

• What is the total size of land required for setting up a citric acid manufacturing plant?

• What is the layout of a citric acid manufacturing plant?

• What are the machinery requirements for setting up a citric acid manufacturing plant?

• What are the raw material requirements for setting up a citric acid manufacturing plant?

• What are the packaging requirements for setting up a citric acid manufacturing plant?

• And more…

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=7628&flag=C

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Citric Acid Manufacturing Plant Project Report: Unit Setup, Cost Analysis and Infrastructure Necessities here

News-ID: 3748348 • Views: …

More Releases from IMARC Group

Hexene Production Plant Setup Cost in 2026: Equipment, Raw Materials, and Invest …

IMARC's new report titled "Hexene Production Cost Analysis Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Hexene production plant. The study covers all the requisite aspects one needs to know while entering the Hexene industry. It offers a comprehensive breakdown of the Hexene production plant setup cost, providing detailed insights into initial capital requirements and infrastructure…

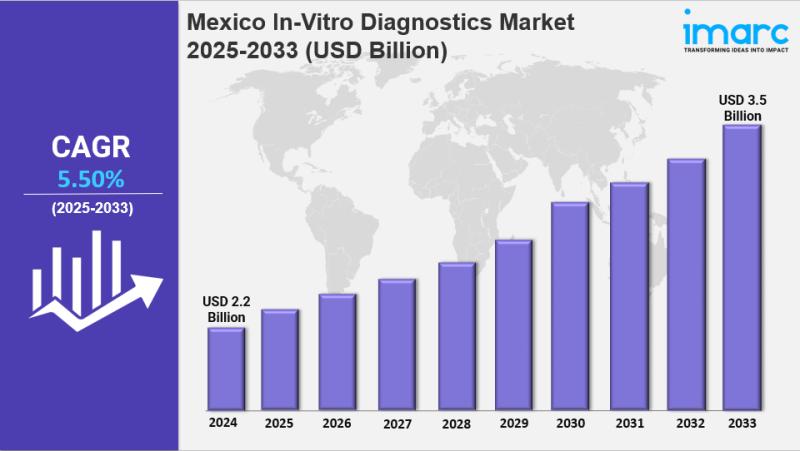

Mexico In-Vitro Diagnostics Market Size, Share, Industry Trends, Growth Factors …

IMARC Group has recently released a new research study titled "Mexico In-Vitro Diagnostics Market Report by Test Type (Clinical Chemistry, Molecular Diagnostics, Immunodiagnostics, Hematology, and Others), Product (Reagents and Kits, Instruments), Usability (Disposable IVD Devices, Reusable IVD Devices), Application (Infectious Disease, Diabetes, Cancer/Oncology, Cardiology, Autoimmune Disease, Nephrology, and Others), End User (Hospitals Laboratories, Clinical Laboratories, Point-of-care Testing Centers, Academic Institutes, Patients, and Others), and Region 2025-2033", offers a detailed analysis…

Bamboo Paper Plant Setup 2025: CAPEX Breakdown & Machinery Sourcing Guide

Bamboo paper is an eco-friendly paper product manufactured using bamboo pulp instead of traditional wood pulp. Bamboo grows rapidly, requires minimal water and chemicals, and regenerates naturally, making it a highly sustainable raw material for the paper industry. Bamboo paper is widely used in printing and writing paper, tissue paper, packaging materials, notebooks, and specialty paper products, offering good strength, smooth texture, and reduced environmental impact compared to conventional paper.

Setting…

Interlocking Paver Blocks Manufacturing Plant Report 2025: Setup Details, Capita …

Interlocking paver blocks are precast concrete paving units designed to interlock with each other, forming a durable and flexible pavement surface. Manufactured using cement, aggregates, sand, and pigments, these blocks are widely used in driveways, walkways, parking areas, industrial floors, roads, and landscaping projects. Their high load-bearing capacity, aesthetic appeal, easy maintenance, and long service life make interlocking paver blocks a preferred alternative to conventional asphalt and concrete pavements.

Setting up…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…