Press release

What Is The Difference Between Inline And End Suction Pumps?

What Is The Difference Between Inline And End Suction Pumps?Inline pumps [https://www.tkflopumps.com/diesel-engine-vertical-turbine-multistage-centrifugal-inline-shaft-water-drainage-pump-product/] and end suction pumps [https://www.tkflopumps.com/cz-horizontal-centrifugal-end-suction-sea-water-seawater-desalination-pump-product/]are two common types of centrifugal pumps used in various applications, and they differ primarily in their design, installation, and operational characteristics. Here are the key differences between the two:

1. Design and Configuration:

Inline Pumps:

Inline pumps have a design where the inlet and outlet are aligned in a straight line. This configuration allows for a compact installation, making them suitable for applications with limited space.

The pump casing is typically cylindrical, and the impeller is mounted directly on the motor shaft.

End Suction Pumps:

End suction pumps have a design where the fluid enters the pump from one end (the suction side) and exits from the top (the discharge side). This design is more traditional and is widely used in various industrial applications.

The pump casing is usually volute-shaped, which helps in converting the kinetic energy of the fluid into pressure.

2. Installation:

Inline Pumps:

Inline pumps are easier to install in tight spaces and can be mounted directly onto piping systems without the need for additional support structures.

They are often used in applications where space is a constraint, such as in HVAC systems.

End Suction Pumps:

End suction pumps require more space for installation due to their larger footprint and the need for additional piping supports.

They are typically used in applications where higher flow rates and pressures are required.

3. Performance:

Inline Pumps:

Inline pumps are generally more efficient at lower flow rates and are suitable for applications that require consistent flow with minimal pressure fluctuations.

They are often used in systems where the flow rate is relatively constant.

End Suction Pumps:

End suction pumps can handle higher flow rates and pressures, making them suitable for a wider range of applications, including water supply, irrigation, and industrial processes.

They are more versatile in terms of performance and can be designed for various operating conditions.

4. Maintenance:

Inline Pumps:

Maintenance can be simpler due to the compact design, but access to the impeller may be limited depending on the installation.

They often have fewer components, which can reduce maintenance needs.

End Suction Pumps:

Maintenance may be more complex due to the larger size and the need to disconnect piping for access to the impeller and other internal components.

They may require more frequent maintenance due to the higher operational stresses.

5. Applications:

Inline Pumps:

Commonly used in HVAC systems, water circulation, and other applications where space is limited and flow rates are moderate.

End Suction Pumps:

Widely used in water supply, irrigation, fire protection systems, and industrial applications where higher flow rates and pressures are needed.

End Suction Pump Vs Double Suction Pump

End-suction centrifugal pumps have a design where water enters the impeller from only one end, while double-suction pumps allow water to enter the impeller from both ends, featuring two inlets.

End Suction Pump

An end suction pump is a type of centrifugal pump characterized by its single suction inlet located at one end of the pump casing. In this design, fluid enters the pump through the suction inlet, flows into the impeller, and is then discharged at a right angle to the suction line. This configuration is commonly used in various applications, including water supply, irrigation, and HVAC systems. End suction pumps are known for their simplicity, compactness, and cost-effectiveness, making them a popular choice for handling clean or slightly contaminated fluids. However, they have limitations in terms of flow capacity and may require higher Net Positive Suction Head (NPSH) to avoid cavitation.

Double Suction Pump [https://www.tkflopumps.com/asnv-series-vertical-double-suction-split-casing-centrifugal-pump-product/]

In contrast, a double suction pump features two suction inlets, allowing fluid to enter the impeller from both sides. This design helps to balance the hydraulic forces acting on the impeller, enabling the pump to handle larger flow rates more efficiently. Double suction pumps are often employed in large-scale applications such as water treatment plants, power generation, and industrial processes where high flow capacity is essential. They are advantageous due to their ability to reduce axial thrust on the impeller, leading to longer operational life and reduced wear. However, the more complex design of double suction pumps can result in higher initial costs and maintenance requirements, as well as a larger footprint compared to end suction pumps.

ASNV series Vertical Double Suction Split Casing Centrifugal Pump [https://www.tkflopumps.com/asnv-series-vertical-double-suction-split-casing-centrifugal-pump-product/]

Model ASN and ASNV pumps are single-stage double suction split volute casing centrifugal pumps and used or liquid transportation for water works, air-conditioning circulation, building, irrigation, drainage pump station, electric power station, industrial water supply system, fire-fighting system, shipbuilding and so on.

Double Suction Pump Application Fields

Municipal, construction, ports

Chemical industry, paper making, paper pulp industry

Mining and metallurgy;

Fire control

Environmental protection

Advantages of End Suction Pump

Reliability and durability

End-suction pumps are known for their exceptional reliability and durability. Its rugged structural design ensures stable performance under harsh working conditions. This reliability makes end-suction pumps popular in various industries.

Diverse sizes and designs

End-suction pumps are available in a variety of sizes and designs, providing the flexibility to adapt to different application needs. Whether it's a small operation or a large industrial project, you'll find the right end-suction pump to meet your specific specifications.

Efficient fluid transfer

Designed for efficient fluid transfer, these pumps provide excellent efficiency in terms of energy consumption. They are able to efficiently handle a variety of traffic flows while maintaining consistent performance. By minimizing energy waste, end-suction pumps save users money over the long term.

Convenience of installation and maintenance

End-suction pumps are relatively simple to install and maintain. Its simple and modular design makes the installation process easy. Additionally, routine maintenance tasks such as inspections, repairs and component replacements can be easily completed, reducing downtime and associated costs.

Convenient interchangeable parts

End-suction pumps feature interchangeable parts for quick and easy maintenance and repair. This feature makes troubleshooting and component replacement efficient, further reducing downtime and improving operational efficiency.

compact design

The compact design of end-suction pumps is a major advantage, allowing them to operate efficiently in limited spaces. This makes them ideal for space-constrained installations. The small footprint ensures flexibility in factory layout and facilitates integration with existing systems.

Cost effective

End-suction pumps provide a more cost-effective fluid transfer solution than other pump types. Its relatively low initial investment, coupled with efficient operation and convenient maintenance, significantly reduces life cycle costs. This affordability makes it ideal for applications with limited budgets.

Versatility

The versatility of end-suction pumps makes them suitable for a wide range of applications. From HVAC systems, water supply and distribution, irrigation to general industrial processes, these pumps meet diverse fluid transfer needs. Its adaptability has enhanced its popularity across industries.

Low noise operation

End-suction pumps are designed for low-noise operation and are suitable for applications where noise control is required, such as residential, commercial buildings or noise-sensitive environments.

ESC series Closed Coupled Mono-block Single Stage End Suction Centrifugal pump [https://www.tkflopumps.com/esc-series-closed-coupled-mono-block-single-stage-end-suction-centrifugal-pump-product/]

- Pumping clean or slightly contaminated water (max.20 ppm) containing no solid particles for circulation, conveying and pressurized water supply.

- Cooling/cold water, sea water and industrial water.

- Applying on municipal water supply, irrigation, building, general industry, power stations, etc.

- Pump assembly composed of pump head, motor and base-plate.

- Pump assembly composed of pump head, motor and iron cushion.

- Pump assembly composed of pump head and motor

- Mechanical seal or packing seal

- Installation and operation instructions

Media Contact

Company Name: Shanghai Tongke Flow Technology Co., Ltd

Contact Person: Tongke Flow T

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-is-the-difference-between-inline-and-end-suction-pumps]

Country: China

Website: https://www.tkflopumps.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What Is The Difference Between Inline And End Suction Pumps? here

News-ID: 3744803 • Views: …

More Releases from ABNewswire

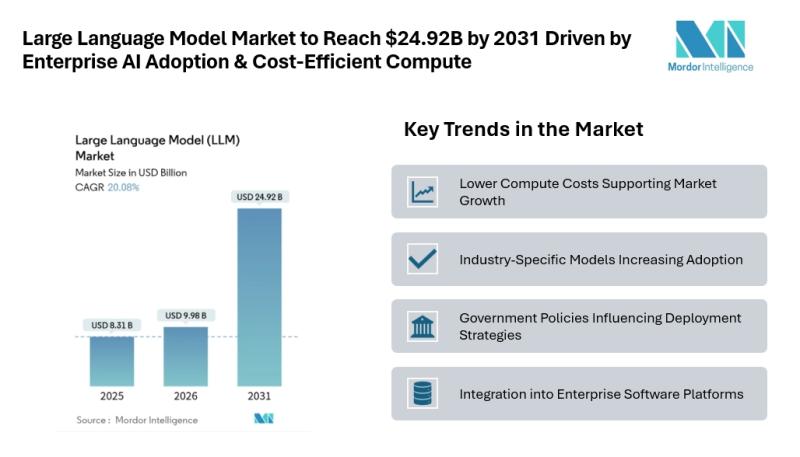

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

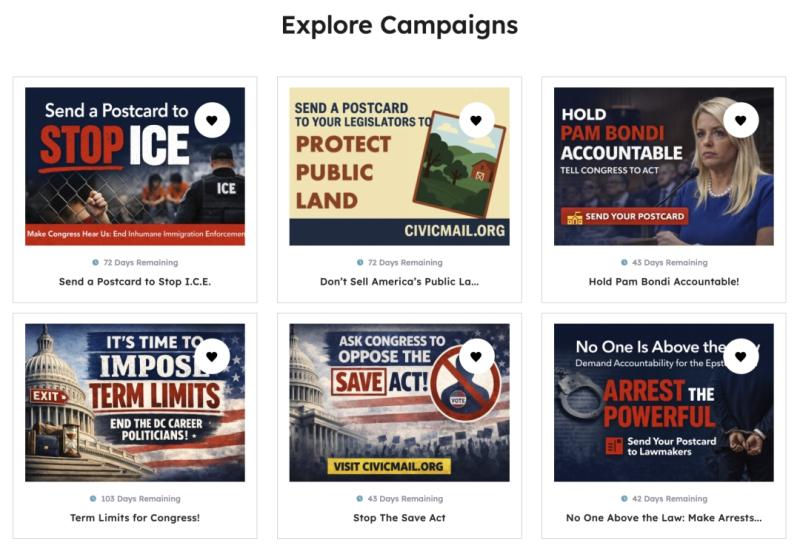

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for Pump

Asphalt Pumps Market Key Players: Johnson Pump, Viking Pump, Rotan Pump, Shanggu …

The Asphalt Pumps Market Research Reports 2021 – 2027 is an Analysis and In-depth study of the Asphalt Pumps Market Industry, with the target of global market trend. The report mainly focuses on the market size, market structure, market share, growth cost structure, and forecast for 2027. The Research Report is an analysis of quantitative of the Asphalt Pumps market and gives information for making strategies…

Automotive Pump Market Forecast to 2028 - Covid-19 Impact and Global Analysis - …

MARKET INTRODUCTION

Automotive pumps are utilized for transferring automotive fluids in the vehicles. These pumps are mainly used for improving vehicle performance and fuel efficiency. The increase in demand for environment-friendly solutions has pushed several manufacturers to design and develop advanced pumps. The pumps are used in various vehicle systems such as coolant, steering, fuel, transmission, and lubrication.

Download Sample Report in PDF Version @ www.theinsightpartners.com/sample/TIPRE00006033/?utm_source=openpr&utm_medium=10387

This report sample includes:

A brief introduction to…

Solar Pump Market Current & Future Growth Forecast To 2027 | CRI Pump, LORENTZ, …

Asia-pacific contributed to the highest share, accounting for more than half of the global solar pump market in 2019, and will maintain its dominance throughout the forecast period. This is attributed to increase in government initiatives in region such as India, drive the market growth in this region. However, Europe is expected to grow at the highest CAGR of 8.5% from 2020 to 2027. This is owing to means of…

Agricultural Pump Market Advancement Outlook 2020-2026: Sulzer, Dayuan Pump, Wil …

The Latest report about the Agricultural Pump market provides a detailed evaluation of the business vertical in question, alongside a brief overview of the industry segments. An exceptionally workable estimation of the present industry scenario has been delivered in the study, and the Agricultural Pump market size with regards to the revenue and volume have also been mentioned. In general, the research report is a compilation of key data with…

Agricultural Water Pump Market Growth Opportunities 2020: Lingxiao Pump, East Pu …

The newly issued research report provides comprehensive and an in-depth assessment of the "Global Agricultural Water Pump Market Forecast 2020-2026", which will also offer relevant data for the new industry entrants as well as well-established Agricultural Water Pump market players. According to the study, the worldwide Agricultural Water Pump market report unfolds the current and historical Agricultural Water Pump industry scenarios, Agricultural Water Pump market development patterns and is expected…

Global Slurry Pump Market: Tsurumi Pump, Shijiazhuang Kingda Pump, Xylem, Weir G …

Global Market Study Evaluate on Slurry Pump Industry by Type, Manufacturers, Application, Type, and Regions, Forecast up to 2022

The scope of the global Slurry Pump market report is:

This report offers a comprehensive evaluation of the Slurry Pump market. It does so by in-depth qualitative insights, historical Slurry Pump market data, and verifiable projections about global Slurry Pump market size. The projections featured in the Slurry Pump market report have been…