Press release

Slip agent for Metalized Cast Polypropylene Film, improve the stripping performance of the release film

Metalized Cast Polypropylene Film (Metalized CPP, mCPP) not only has the characteristics of plastic film, but also replaces aluminium foil to a certain extent, playing a role in improving the product grade, and the cost is lower, in the biscuits, leisure food packaging is widely used. However, in the production process, Metalized CPP film often occurs uneven adhesion of the aluminized layer or easy to fall off and other problems, so that the product performance degradation, and even serious and even affect the quality of the contents of the package.Reasons for uneven adhesion or easy peeling of the aluminised layer of Metalized Cast Polypropylene Film (Metalized CPP, mCPP) may include:

1. Inappropriate choice of resin: If the polypropylene resin used is not suitable for the aluminium plating process, insufficient adhesion may result. A polypropylene resin suitable for aluminising should be selected.

2. Inappropriate use of additives: Certain additives may affect the adhesion between the aluminised layer and the polypropylene substrate. For example, slip agents, antistatic agents, etc. may migrate to the surface and affect the adhesion. additives in the CPP substrate (amide low molecular weight slip agents) migrate to the aluminium plating processing surface and collect between the aluminium plating processing surface of the CPP film and the aluminium plating layer, reducing the adhesion of the aluminium plating layer on the CPP substrate, thus making the aluminium plating layer more susceptible to transferring or peeling off etc.

3. Inadequate surface treatment: Prior to aluminising, the surface of the polypropylene film needs to be properly treated, e.g. corona treatment, to increase surface energy and adhesion. Inadequate surface treatment may result in uneven adhesion.

4. Inadequate post-treatment: After aluminising, the film may require further treatment, such as curing, to ensure the stability of the aluminised layer. If post-treatment is not done properly, it may result in a loss of adhesion.

Solving these problems usually requires optimising the production process, choosing the right materials and additives, and ensuring good maintenance of the production equipment.

SILIKE non-migratory super slip additives [https://www.siliketech.com/sf-series-super-slip-masterbatch/], better slip agent for Metalize CPP films.

SILIKE non-Blooming slip agent SF205 [https://www.siliketech.com/slip-silicone-masterbatch-sf205-for-boppcpp-blown-films-product/] is especially suitable for polypropylene cast film and BOPP film. In order to provide good anti-blocking smoothening performance, it should be directly added to the surface layer of the film. The product only contains the smooth component and can be used independently with the anti-blocking agent.

The benefits of SILIKE non-precipitation slip agent masterbatch SF205:

1. Applied to PP film, it can significantly improve the anti-blocking and smoothness of the film and avoid the adhesion during the film production. SILIKE non-Blooming slip agent SF205 can greatly reduce the dynamic and static friction coefficient of the film surface.

2. Under extremely harsh conditions such as high temperature, due to the particularity of polysiloxane structure, the film will keep a stable long-term smoothness.

3. SILIKE Non-Migratory Slip Additives SF205 can improve the stripping performance of the release film, reduce the stripping force and reduce the stripping residue.

4. SILIKE non-Blooming slip agent SF205 can effectively solve the "powder out" phenomenon of film products.

5. In the high temperature environment, it can still maintain a low friction coefficient, SILIKE non-precipitation slip agent masterbatch SF205 can be applied to high-speed pack cigarette film that need to have good hot and smooth performance.

6. Due to the smoothing agent component contains silicone chain segments, SILIKE non-Blooming slip agent SF205 has good processing lubricity, and can improve processing efficiency and also improve the production performance during the the production process.

Notes: SILIKE non-precipitation slip agent masterbatch SF205 has good processing performance, therefore, in the early processing it may clean out of leftover material or inpurity from the equipment, and result in the film crystal point increasing phenomenon, but after the production becomes stable, the film performance is not affected.

If you need high-performance film slip agents [https://www.siliketech.com/super-slip-masterbatch/], contact SILIKE. We have extensive experience with cast and blown films and have provided effective processing solutions for many film packaging manufacturers.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website: www.siliketech.com [https://www.siliketech.com/] to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=slip-agent-for-metalized-cast-polypropylene-film-improve-the-stripping-performance-of-the-release-film]

Country: China

Website: https://www.siliketech.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Slip agent for Metalized Cast Polypropylene Film, improve the stripping performance of the release film here

News-ID: 3718580 • Views: …

More Releases from ABNewswire

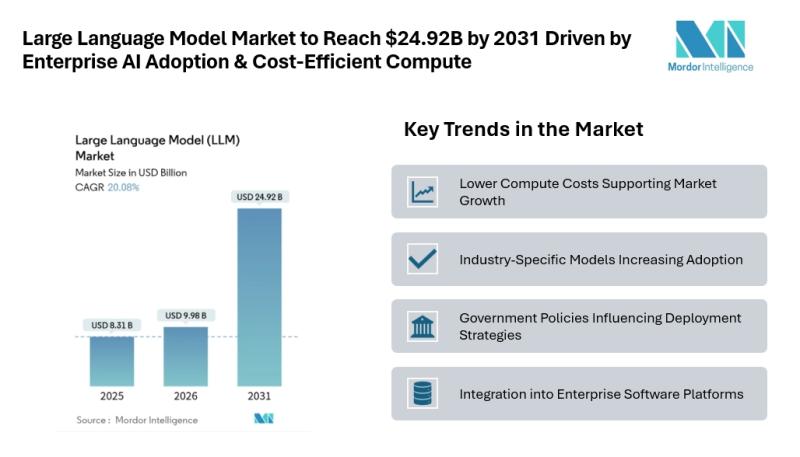

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

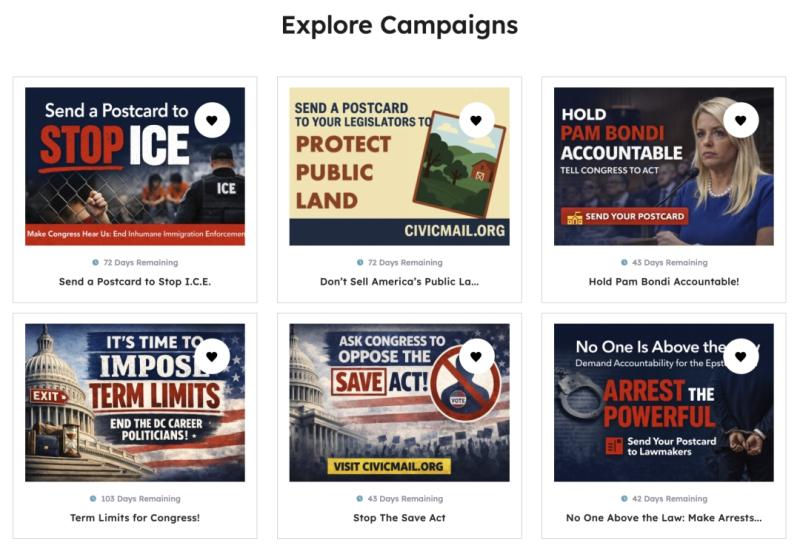

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for SILIKE

Silicone Powder Applications and Benefits: Elevate Product Performance with SILI …

Unlock the potential of silicone powder - a high-performance, micronized additive designed to enhance surface properties, streamline processing, and deliver exceptional slip and anti-scratch functionality across multiple industries. From thermoplastics and coatings to personal care and rubber compounds, silicone powder brings measurable improvements in quality and efficiency.

What Is Silicone Powder?

Silicone powder is a fine, white, micronized additive composed of ultra-high molecular weight siloxane polymer dispersed in silica. It's primarily used…

Enhance EVA Film Production with SILIKE SILIMER 2514E

EVA film, short for Ethylene Vinyl Acetate film, is a versatile material made from a copolymer of ethylene and vinyl acetate. It's widely used across various industries due to its unique properties, such as flexibility, transparency, durability, and strong adhesion. The vinyl acetate content in EVA can be adjusted during production, allowing manufacturers to tailor its characteristics, like softness, toughness, or clarity, to suit specific applications. Common uses include solar…

Tree Planting Day Special: SILIKE Sows Seeds of Green, Building a Sustainable Sm …

Spring breezes gently brush, and green sprouts begin to emerge. Today, March 12, is Tree Planting Day, marking a significant milestone in SILIKE's green initiatives! In alignment with China's "Dual Carbon" strategy, Chengdu SILIKE Technology Co., Ltd., driven by its mission to empower ecology through technology, joined hands with all employees to launch a unique Tree Planting Day activity titled "Green for the Future, Building a Sustainable Smart Manufacturing Home."…

Christmas Greetings and Future Prospects from SILIKE

As the bells of Christmas ring out, spreading warmth and joy, SILIKE would like to extend our sincerest holiday greetings to all our esteemed clients. May this Christmas season fill your lives with love, laughter, and prosperity, and bring you closer to your dearest ones.

Over the past years, we have been on an incredible journey together, exploring the vast potential of our environmentally friendly, skin-friendly silicone-based thermoplastic elastomer materials -…

SILIKE anti-squeak masterbatch, Provides permanent noise reduction for PC/ABS

PC/ABS materials are more commonly used for lifting brackets for display devices and are also commonly used for automotive interiors.

Many components used in automotive instrument panels, center consoles, and trim are made from polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) blends. These materials are prone to squeaking, which is caused by friction and vibration when two parts move against each other (stick-slip action).

Currently, common solutions include covering soft rubber materials, coating lubricants on the surface,…

Celebrating the 20th anniversary of Thermoplastic Vulcanizate Manufacturer SILIK …

Chengdu Silike Technology Co., Ltd. is a technologically innovative enterprise integrating R&D, production and sales, as well as a Vegan Leather Manufacturer, Sustainable Leather Manufacturer, Silicone Elastomer Manufacturer and Thermoplastic Elastomers Overmolding Manufacturer. Since its establishment in 2004, SILIKE has been focusing on the application of silicone in the field of polymer materials, dedicated to improving the processing performance and surface properties of materials, and providing Performance Materials and Performance…