Press release

Friction Stir Welding Market Set for USD 367.05 Million Growth by 2030

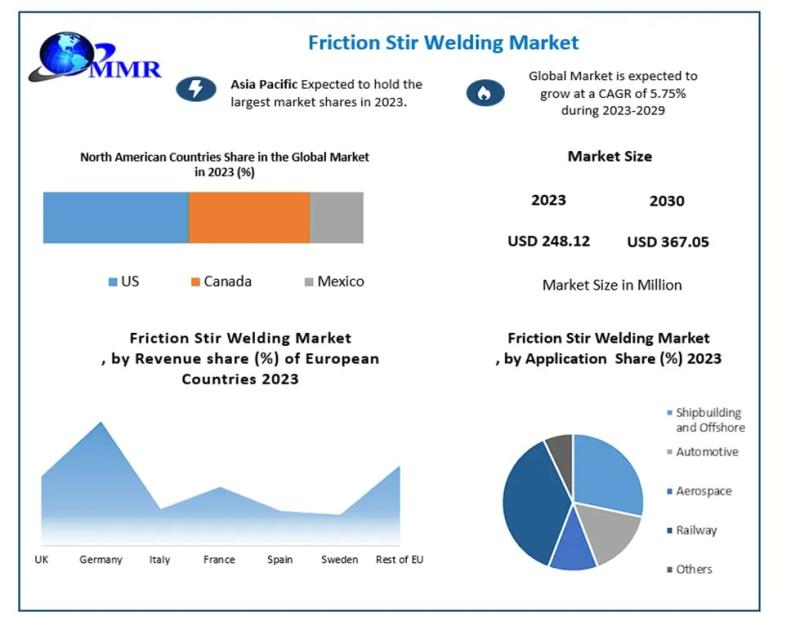

The 𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 size was valued at USD 248.12 Million in 2023 and the total Friction Stir Welding Market revenue is expected to grow at a CAGR of 5.75% from 2024 to 2030, reaching nearly USD 367.05 Million.𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰:

Friction stir welding (FSW) is a revolutionary solid-state welding technique that joins two materials without melting them, utilizing a non-consumable rotating tool to generate frictional heat at the interface of the workpieces. This process allows for the creation of strong, high-quality joints while eliminating the need for flux, filler metal, or shielding gas. The friction stir welding market is witnessing significant growth due to its increasing adoption in industries such as automotive, aerospace, and electronics, where the demand for lightweight and durable components is paramount. Regions such as North America and Europe are leading the market, bolstered by advancements in technology and increasing investments in research and development.

𝐂𝐮𝐫𝐢𝐨𝐮𝐬 𝐀𝐛𝐨𝐮𝐭 𝐎𝐮𝐫 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬? 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐘𝐨𝐮𝐫 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 :https://www.maximizemarketresearch.com/request-sample/10856/

𝐃𝐫𝐢𝐯𝐞𝐫𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭:

Several key factors are propelling the friction stir welding market forward. One of the primary drivers is the technology's ability to enhance the mechanical properties of welded materials, including improved fatigue resistance, strength, and durability. As industries increasingly prioritize efficiency and quality, the demand for advanced welding solutions like FSW has surged. Additionally, the automotive sector's ongoing transition toward electric and lightweight vehicles has further fueled interest in FSW, as manufacturers seek efficient methods to produce high-quality joints in various components.

Another significant driver is the growing emphasis on sustainable manufacturing processes. Friction stir welding's solid-state nature reduces energy consumption and material waste compared to traditional welding methods, making it an attractive option for companies looking to minimize their environmental footprint. With rising regulatory pressure and consumer awareness regarding sustainability, FSW presents an opportunity for industries to adopt greener practices while maintaining high standards of production quality.

𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐓𝐫𝐞𝐧𝐝𝐬:

The friction stir welding market is witnessing notable trends that highlight its growing importance in various sectors. One prominent trend is the increasing automation of FSW processes, as manufacturers invest in advanced robotics and automation technologies to enhance productivity and precision. Automated systems not only reduce labor costs but also ensure consistent weld quality, making them appealing to industries with stringent quality control requirements. Furthermore, the integration of smart technologies, such as data analytics and real-time monitoring, is enhancing the efficiency of FSW operations and enabling manufacturers to optimize their welding processes.

𝐓𝐡𝐞 𝐈𝐧𝐭𝐞𝐫𝐞𝐬𝐭𝐞𝐝 𝐒𝐭𝐚𝐤𝐞𝐡𝐨𝐥𝐝𝐞𝐫𝐬 𝐜𝐚𝐧 𝐄𝐧𝐪𝐮𝐢𝐫𝐞 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐏𝐮𝐫𝐜𝐡𝐚𝐬𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 :https://www.maximizemarketresearch.com/inquiry-before-buying/10856/

𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐩𝐩𝐨𝐫𝐭𝐮𝐧𝐢𝐭𝐢𝐞𝐬:

The friction stir welding market is ripe with opportunities, especially as industries continue to seek advanced manufacturing solutions. The growing demand for lightweight and high-strength materials in sectors such as automotive and aerospace presents a significant opportunity for FSW. As electric and hybrid vehicles become more prevalent, the need for innovative welding techniques that can efficiently join lightweight materials will drive the market forward. Additionally, advancements in FSW technology, such as the development of hybrid systems that combine FSW with other welding techniques, could further broaden the scope of applications and enhance market growth.

𝐖𝐡𝐚𝐭 𝐢𝐬 𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐈𝐧𝐬𝐢𝐠𝐡𝐭?

The Asia Pacific region is poised to become a dominant force in the friction stir welding market, driven by substantial growth in the automotive, railway, aerospace, and defense industries. Countries like China and India are leading the charge, with China maintaining its status as a global leader in vehicle production and sales. The country's substantial investment in electric vehicle production and advanced manufacturing techniques underscores the potential for friction stir welding applications in vehicle assembly. As the region's industrial landscape continues to evolve, the demand for FSW technology will likely rise, supported by the need for high-quality welds in lightweight materials.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐅𝐮𝐥𝐥 𝐏𝐃𝐅 𝐒𝐚𝐦𝐩𝐥𝐞 𝐂𝐨𝐩𝐲 𝐨𝐟 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐩𝐨𝐫𝐭 @https://www.maximizemarketresearch.com/request-sample/10856/

𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬 𝐨𝐟 𝐭𝐡𝐞 𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭:

by Equipment Type

Fixed Friction Stir Welding

Adjustable Friction Stir Welding

Self-reacting Friction Stir Welding

by Material

Aluminium alloy

Magnesium

Titanium

Copper

Steel alloys

Others

by Application

Shipbuilding and Offshore

Automotive

Aerospace

Railway

Others

𝐖𝐡𝐨 𝐢𝐬 𝐭𝐡𝐞 𝐥𝐚𝐫𝐠𝐞𝐬𝐭 𝐦𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐞𝐫𝐬 𝐨𝐟 𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 𝐒𝐭𝐢𝐫 𝐖𝐞𝐥𝐝𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐰𝐨𝐫𝐥𝐝𝐰𝐢𝐝𝐞?

1. Concurrent Technologies Corp. - USA

2. FOOKE GmbH - Germany

3. Gatwick Technologies Ltd. - UK

4. HFW Solutions LLC - USA

5. Hitachi High-Technologies Corp. - Japan

6. Manufacturing Technology, Inc. (MTI) - USA

7. Midea Group (KUKA AG) - China/Germany

8. Norsk Hydro ASA - Norway

9. PaR Systems LLC - USA

10. Yamazaki Mazak Corp. - Japan

11. Beijing FSW Technology Co., Ltd. - China

12. The ESAB Group, Inc. - USA (part of Colfax Corporation)

13. KUKA Systems GmbH - Germany

14. MegaStir - USA

15. Eta Technology Private Limited - India

16. Grenzebach Maschinenbau GmbH - Germany

17. Colfax Corporation (ESAB) - USA

18. Schlumberger Limited - USA

𝐅𝐨𝐫 𝐦𝐨𝐫𝐞 𝐢𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧 𝐚𝐛𝐨𝐮𝐭 𝐭𝐡𝐢𝐬 𝐫𝐞𝐩𝐨𝐫𝐭 𝐯𝐢𝐬𝐢𝐭 :https://www.maximizemarketresearch.com/market-report/global-friction-stir-welding-market/10856/

𝐊𝐞𝐲 𝐎𝐟𝐟𝐞𝐫𝐢𝐧𝐠𝐬:

Past Market Size and Competitive Landscape

Friction Stir Welding Market Size, Share, Size & Forecast by different segment

Market Dynamics - Growth Drivers, Restraints, Opportunities, and Key Trends by region

Friction Stir Welding Market Segmentation - A detailed analysis by Product

Competitive Landscape - Profiles of selected key players by region from a strategic perspective

Competitive landscape - Market Leaders, Market Followers, Regional player

Competitive benchmarking of key players by region

PESTLE Analysis

PORTER's analysis

Value chain and supply chain analysis

Legal Aspects of business by region

Lucrative business opportunities with SWOT analysis

Recommendations

𝐅𝐨𝐫 𝐚𝐝𝐝𝐢𝐭𝐢𝐨𝐧𝐚𝐥 𝐫𝐞𝐩𝐨𝐫𝐭𝐬 𝐨𝐧 𝐫𝐞𝐥𝐚𝐭𝐞𝐝 𝐭𝐨𝐩𝐢𝐜𝐬, 𝐯𝐢𝐬𝐢𝐭 𝐨𝐮𝐫 𝐰𝐞𝐛𝐬𝐢𝐭𝐞:

♦ Global Smart Parking System Market https://www.maximizemarketresearch.com/market-report/global-smart-parking-system-market/15067/

♦ Collagen Market https://www.maximizemarketresearch.com/market-report/global-collagen-market/37222/

♦ Global Yeast Nutrients Market https://www.maximizemarketresearch.com/market-report/global-yeast-nutrients-market/73280/

♦ Global Industrial Controls System Market https://www.maximizemarketresearch.com/market-report/global-industrial-controls-system-market/33096/

♦ Global Fatty Amides Market https://www.maximizemarketresearch.com/market-report/global-fatty-amides-market/6359/

♦ Ventilator Market Europe https://www.maximizemarketresearch.com/market-report/ventilator-market-europe/1951/

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡:

MAXIMIZE MARKET RESEARCH PVT. LTD.

⮝ 3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

✆ +91 9607365656

🖂 sales@maximizemarketresearch.com

🌐 www.maximizemarketresearch.com

𝐀𝐛𝐨𝐮𝐭 𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡:

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Friction Stir Welding Market Set for USD 367.05 Million Growth by 2030 here

News-ID: 3708573 • Views: …

More Releases from MAXIMIZE MARKET RESEARCH PVT. LTD

Wine Production Machinery Market Growing at a Robust CAGR of 6.4% Driven by Auto …

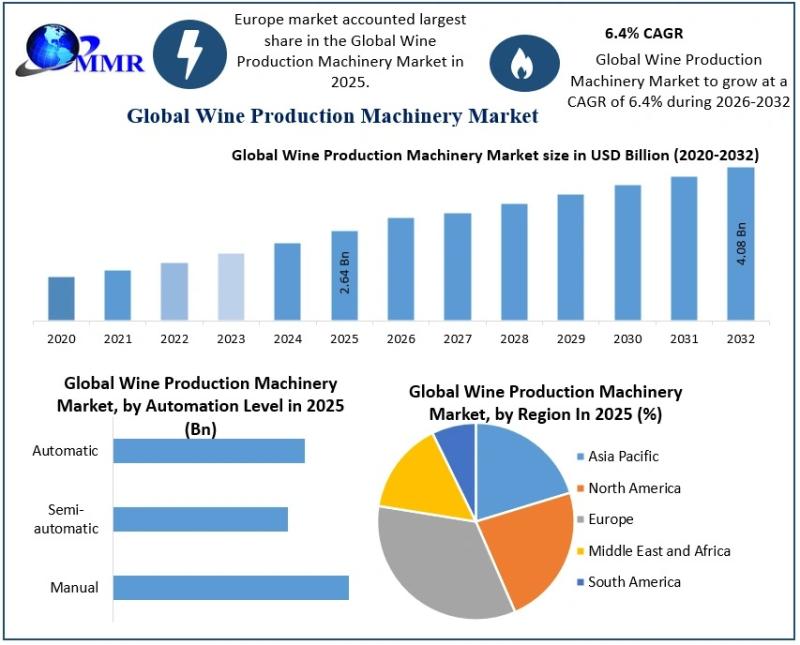

The Wine Production Machinery Market size was valued at USD 2.64 Billion in 2025 and the total Wine Production Machinery revenue is expected to grow at a CAGR of 6.4% from 2026 to 2032, reaching nearly USD 4.08 Billion by 2032.

Wine Production Machinery Market Overview:

The Wine Production Machinery Market is witnessing steady transformation as wineries across the globe increasingly adopt modern equipment to enhance efficiency, consistency, and product quality. From…

Fusion Energy Market Outlook Highlights Strong Growth at 7.4% CAGR

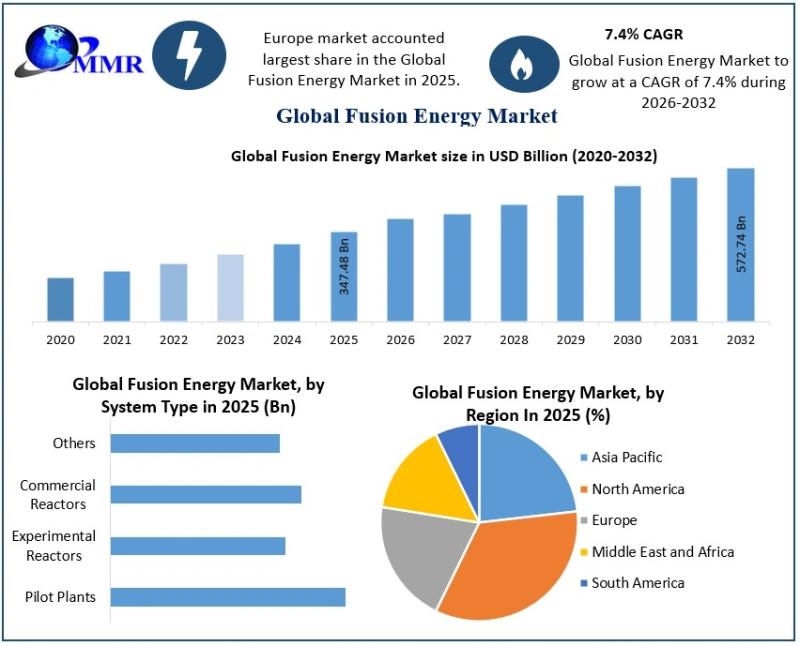

The Fusion Energy Market size was valued at USD 347.48 Billion in 2025 and the total Fusion Energy revenue is expected to grow at a CAGR of 7.4% from 2026 to 2032, reaching nearly USD 572.74 Billion by 2032.

Fusion Energy Market Overview:

The Fusion Energy Market is gaining global attention as nations, industries, and researchers intensify efforts to develop cleaner and more sustainable power alternatives for the future. Fusion energy is…

India Gold Loan Market Shows Strong Momentum Driven by Trust, Technology, and Fi …

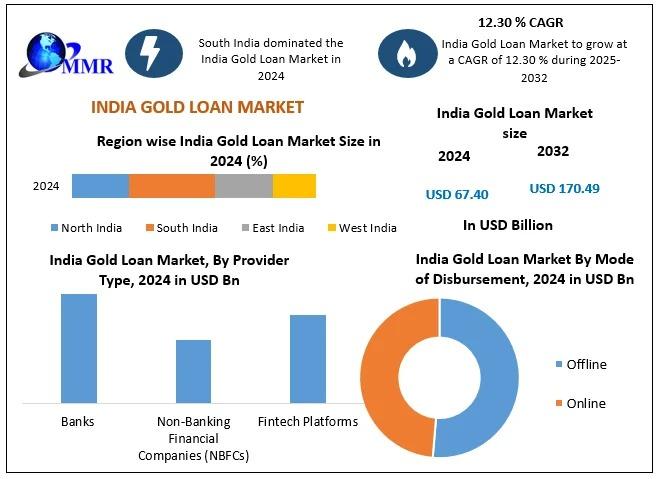

The India Gold Loan Market size was valued at USD 67.40 Billion in 2024 and the total India Gold Loan Market is expected to grow at a CAGR of 12.30 % from 2025 to 2032, reaching nearly USD 170.49 Billion.

India Gold Loan Market Overview:

The India Gold Loan Market has steadily evolved into a trusted financial solution for individuals and small businesses seeking quick access to funds without liquidating their long-term…

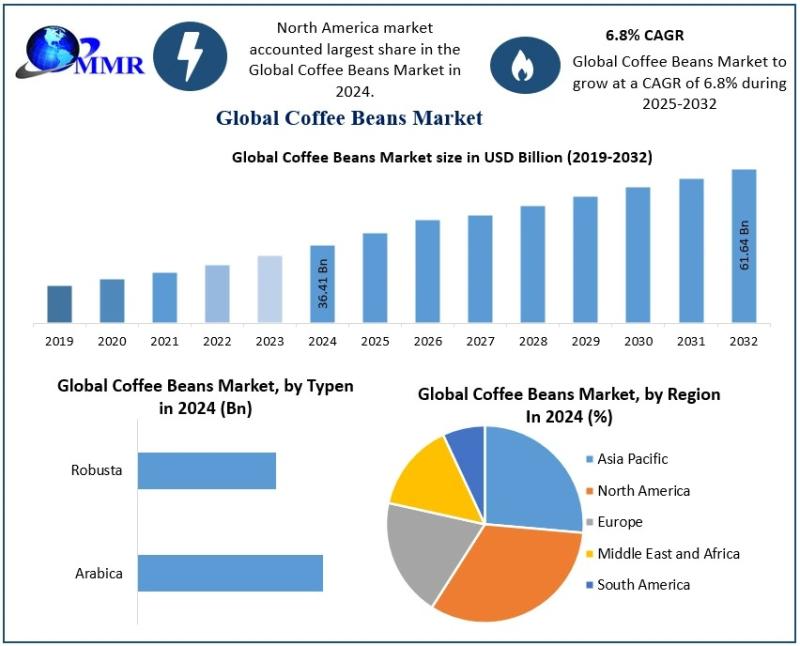

Coffee Beans Market Trends Highlight Rising Demand for Specialty, Sustainable, a …

The Coffee Beans Market size was valued at USD 36.41 Billion in 2024 and the total Coffee Beans revenue is expected to grow at a CAGR of 6.8% from 2025 to 2032, reaching nearly USD 61.64 Billion.

Coffee Beans Market Overview:

The Coffee Beans Market reflects a complex ecosystem that begins at farms and extends to global distribution networks. Coffee beans are cultivated across diverse climatic regions, each contributing unique taste profiles…

More Releases for Friction

Friction Products and Materials Market Is Booming Worldwide | Tenneco, Carlisle …

The latest research study released by AMA on the Friction Products and Materials Market offers over 181 pages of analysis on business strategies employed by key and emerging industry players. It provides insights into current market developments, landscape, technologies, drivers, opportunities, market outlook, and status. The market study is segmented by key regions driving market growth. The Friction Products and Materials study combines qualitative and quantitative market data, primarily collected…

Friction Materials Market Analysis By Top Keyplayers - ABS FRICTION CORP., Akebo …

The "Friction Materials Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Friction Materials Market, 2024-2031

Verified Market Research's most recent report, "Friction Materials Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth…

Friction Modifiers Market, By Type (Organic Friction Modifiers and Inorganic Fri …

Data Bridge Market Research analyses that the friction modifiers market will witness a CAGR of 9.7% for the forecast period of 2022-2029. Friction modifiers market report analyses the growth, due to accelerating application of friction modifiers in advertising and promotions of various brands.

Friction modifiers, also known as boundary lubrication additives, are oil-soluble chemicals used in lubricants as transmission and internal combustion engine additives. These lubricants are used in machine components…

Friction Product Market 2027 Worldwide Analysis on Revenue, Segmentation and Key …

MARKET INTRODUCTION

Friction products are used to produce friction in order to reduce the velocity or stop the movement of a particular object. Friction is the resistance which opposes the movement of object. Friction products cover wide range of pads, linings, blocks, rolls, sheets, clutches etc. Commonly used materials in friction based products are paper (cotton or cellulose fiber and phenolic resin mixture), elastomerics, graphitics, sintered metal ceramics, advanced fibers and…

Global Friction Products and Materials Market 2018 Top Players are: ABS Friction …

Friction material is used in every-day mundane applications such as automotive brakes and clutches to commercial and industrial applications.

According to this study, over the next five years the Friction Products and Materials market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019. In particular, this report presents the global market share (sales and…

GMP Friction Products Develops Friction Materials for Wind Energy Turbine Market …

Brakes Stop and Hold Wind Turbine Blades for Emergency, High Winds or Maintenance

AKRON, OHIO (January 19, 2012) – GMP Friction Products, working with wind turbine manufacturers and the suppliers to the OEM market, has developed high-speed friction brake materials designed to reduce rotational speed below maximum value or bring the blades of a wind energy turbine to a standstill. Following more than 1,000 braking sequence tests, they have developed friction…