Press release

Metal Injection Molding (MIM) Market: A Growing Trend in Manufacturing

Metal Injection Molding (MIM) is a manufacturing process that involves injecting a powdered metal mixture into a mold and then sintering it to produce complex metal parts. This technology has gained significant traction in recent years, driven by its ability to produce high-quality, intricate components at a relatively low cost. This post will delve into the MIM market, exploring its size, share, opportunities, challenges, demand, and trends.Market Size and Share

Data Bridge Market Research analyses that the global Metal Injection Molding (MIM) market is expected to reach USD 8,240.36 million by 2031 from USD 4,277.50 million in 2023, growing with a substantial CAGR of 8.60% in the forecast period of 2024 to 2031.

For more Information, visit https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

The MIM market is a substantial segment of the global manufacturing industry. While precise figures can vary depending on data sources and regional factors, the market is estimated to be worth billions of dollars. Key players in the market include established manufacturing companies, specialized MIM service providers, and technology developers.

Market Opportunities

The MIM market presents several significant opportunities:

Complex part production: MIM is particularly well-suited for producing complex and intricate metal parts that would be difficult or expensive to manufacture using traditional methods.

Miniaturization: MIM enables the production of miniature components, which are essential in various industries, including electronics, medical devices, and aerospace.

Cost-effectiveness: MIM can be more cost-effective than traditional manufacturing methods, especially for high-volume production of complex parts.

Material versatility: MIM can be used with a wide range of metal powders, allowing for the production of parts with varying properties and characteristics.

Customization: MIM offers a high degree of customization, enabling the production of parts with specific tolerances, finishes, and properties.

Market Challenges

Despite its growth potential, the MIM market faces several challenges:

Initial investment: The upfront investment required to set up a MIM facility can be substantial, limiting entry into the market for smaller companies.

Technological complexities: MIM is a complex process that requires specialized equipment and expertise. Ensuring process control and quality can be challenging.

Material limitations: While MIM can be used with a wide range of metal powders, there are limitations in terms of the types of materials that can be processed.

Environmental concerns: The sintering process used in MIM can generate emissions and waste, which must be managed in accordance with environmental regulations.

Competition: The MIM market is becoming increasingly competitive, with numerous players vying for market share.

Market Demand

The demand for MIM is driven by several factors:

Miniaturization: The trend towards smaller and more compact electronic devices and medical components is driving demand for miniature metal parts that can be produced using MIM.

Customization: The ability to customize MIM parts to meet specific requirements is driving demand in industries such as aerospace, automotive, and medical devices.

Cost-effectiveness: MIM can offer significant cost savings compared to traditional manufacturing methods, particularly for high-volume production.

Product quality: MIM can produce parts with high precision and consistency, meeting the demanding quality standards of many industries.

Regulatory compliance: MIM can help companies comply with regulatory requirements related to product safety and performance.

Market Trends

Several key trends are shaping the MIM market:

Advanced materials: The development of new metal powders and materials is expanding the range of applications for MIM.

Automation: The increasing automation of MIM processes is improving efficiency and reducing costs.

Integration with other technologies: MIM is being integrated with other manufacturing technologies, such as 3D printing and additive manufacturing, to create more complex and innovative products.

Sustainability: There is a growing emphasis on sustainability in manufacturing, and MIM can contribute to this by reducing waste and improving resource efficiency.

Emerging markets: The growth of emerging markets, particularly in Asia, is creating new opportunities for MIM as these regions expand their manufacturing capabilities.

Browse Trending reports:

Global Women Nutrition Market - Industry Trends and Forecast to 2031 https://www.databridgemarketresearch.com/reports/global-women-nutrition-market

Global Phenol Market - Industry Trends and Forecast to 2031 https://www.databridgemarketresearch.com/reports/global-phenol-market

Global Unmanned Ground Vehicle Market - Industry Trends and Forecast to 2031 https://www.databridgemarketresearch.com/reports/global-unmanned-ground-vehicle-market

Global Testing, Inspection, and Certification (TIC) Market for Building and Construction - Industry Trends and Forecast to 2031 https://www.databridgemarketresearch.com/reports/global-testing-inspection-and-certification-tic-market

In conclusion, the MIM market is a growing industry, driven by the need for complex, high-quality metal parts. As technology continues to advance and the demand for customized and miniaturized components increases, the MIM market is expected to experience further expansion and innovation.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: Corporatesales@databridgemarketresearch.com

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding (MIM) Market: A Growing Trend in Manufacturing here

News-ID: 3666176 • Views: …

More Releases from Data Bridge Market Research

Scented Candle Market Shows Strong Growth Driven by Wellness and Home Décor Tr …

The global scented candle market is on track for significant expansion, increasing from an estimated USD 3.60 billion in 2024 to USD 6.00 billion by 2032, registering a strong CAGR of 6.60%. Rising consumer interest in home ambiance, wellness, and premium lifestyle products continues to drive market demand.

Get More Detail: https://www.databridgemarketresearch.com/reports/global-scented-candle-market

Market Growth Drivers

The scented candle market has evolved beyond being just a decorative item. Key growth factors include:

Home Fragrance &…

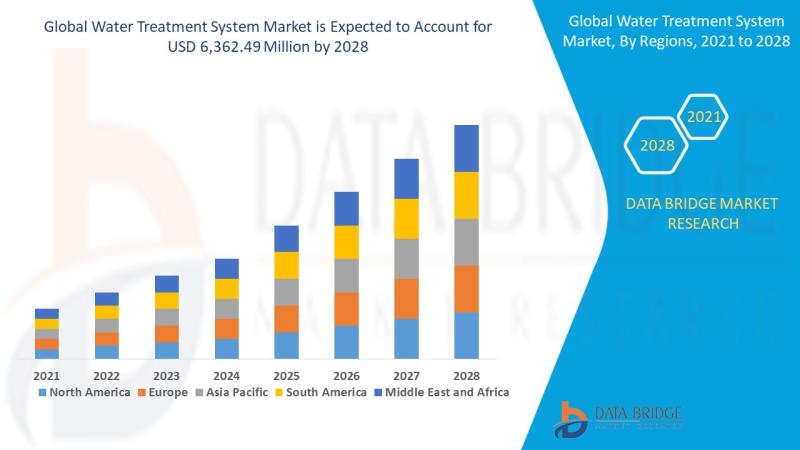

Water Treatment System Market: Sustaining the Future of Clean Water

Introduction

Understanding Water Treatment Systems

Water treatment systems are designed to purify and disinfect water for various uses-drinking, industrial processes, irrigation, and wastewater reuse. These systems eliminate contaminants such as bacteria, viruses, heavy metals, chemicals, and particulates, making water safe and sustainable for consumption and use.

Importance in Global Sustainability

Clean water is essential to life and industrial progress. With growing water demand and pollution, water treatment systems are now critical infrastructure across the…

Veterinary X-Ray Market Size, Analysis, Scope, Demand, Opportunities, Statistics

According to Data Bridge Market Research The global Veterinary X-Ray market size was valued at USD 915.19 million in 2024 and is projected to reach USD 1576.00 million by 2032, with a CAGR of 7.03 % during the forecast period of 2025 to 2032.

With increasing globalization and digital disruption, the Equine X-Ray Solutions Market is expanding across multiple industries, . Market research data indicates that businesses in the Companion Animal…

Veterinary X-Ray Market Size, Analysis, Scope, Demand, Opportunities, Statistics

According to Data Bridge Market Research The global Veterinary X-Ray market size was valued at USD 915.19 million in 2024 and is projected to reach USD 1576.00 million by 2032, with a CAGR of 7.03 % during the forecast period of 2025 to 2032.

With increasing globalization and digital disruption, the Equine X-Ray Solutions Market is expanding across multiple industries, . Market research data indicates that businesses in the Companion Animal…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…