Press release

Metal Forging Market Projected to Reach $153.9 Billion by 2031, Driven by Infrastructure Growth and Technological Innovations

The global metal forging market is poised for significant expansion, with projections estimating its valuation to reach $153.9 billion by 2031, growing at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2031. This growth is driven by several factors, including the rising demand for forged metal components in the automotive and aerospace industries, increasing infrastructure development, and advancements in forging technologies. However, the market also faces challenges, such as the energy-intensive nature of forging processes, fluctuating raw material costs, and environmental concerns. Despite these obstacles, the metal forging industry presents substantial opportunities for growth, particularly through the adoption of Industry 4.0 technologies and innovations in forging methods.Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5879

Introduction to Metal Forging

Metal forging is a manufacturing process that involves shaping metal using compressive forces, typically delivered by hammers, presses, or dies. This process is crucial for producing a wide range of components used in various industries, including automotive, aerospace, construction, oil and gas, and machinery. Forged components are known for their superior strength, durability, and resistance to fatigue, making them ideal for applications that require high-performance materials.

The metal forging market has evolved significantly over the years, with advancements in technology leading to improved efficiency, precision, and capabilities. Today, the industry is characterized by a diverse range of forging methods, materials, and end-use applications, each contributing to the market's overall growth.

Key Drivers of Market Growth

1. Infrastructure Development

One of the most significant drivers of the metal forging market is the ongoing surge in infrastructure development worldwide. Governments and private entities are investing heavily in building and upgrading infrastructure, including roads, bridges, airports, and power plants. These projects require a wide range of forged metal components, from structural steel to machinery parts, driving demand in the forging industry.

In emerging economies, rapid urbanization and industrialization are leading to increased construction activities, further fueling the demand for forged components. For example, countries in Asia-Pacific, such as China and India, are witnessing a boom in infrastructure projects, which is expected to continue over the next decade. This trend is contributing to the growth of the metal forging market in the region, making it a key area of focus for industry players.

2. Rising Demand in the Automotive Industry

The automotive industry is one of the largest consumers of forged metal components, accounting for a significant share of the market. Forged parts are used in critical applications within vehicles, such as engines, transmissions, drivetrains, and chassis components. The durability and strength of forged components make them essential for ensuring the safety and reliability of vehicles.

The increasing production of automobiles, particularly in developing regions, is driving the demand for forged metal components. Additionally, the shift towards electric vehicles (EVs) is creating new opportunities for the forging industry. While EVs have fewer moving parts compared to traditional internal combustion engine vehicles, they still require high-quality forged components for critical applications such as battery housings, powertrain elements, and suspension systems. The ongoing transition to EVs is expected to drive further growth in the metal forging market.

3. Growth in the Aerospace Industry

The aerospace industry is another key driver of the metal forging market, with forged components playing a critical role in aircraft manufacturing. The production of commercial aircraft is on the rise, driven by increasing air travel and the expansion of airline fleets, particularly in Asia-Pacific and the Middle East. Forged metal parts are essential for the construction of aircraft engines, landing gear, and structural elements, where strength, precision, and reliability are paramount.

The demand for forged components in the aerospace industry is also supported by advancements in materials and forging technologies. For instance, the use of lightweight materials such as titanium and aluminum alloys in aerospace applications is increasing, driven by the need for fuel efficiency and reduced emissions. These materials are often forged to create high-performance components that meet the stringent requirements of the aerospace industry.

Challenges Facing the Metal Forging Market

1. Energy-Intensive Processes

One of the most significant challenges facing the metal forging market is the energy-intensive nature of the forging process. Forging requires substantial amounts of energy to heat and shape metal, making the industry highly susceptible to fluctuations in energy prices. As global energy costs continue to rise, manufacturers may face increased production costs, which could impact profitability and hinder market growth.

In addition to the financial implications, the high energy consumption associated with forging processes raises environmental concerns. The industry is under increasing pressure to reduce its carbon footprint and adopt more sustainable practices. This challenge is driving research and development efforts aimed at improving energy efficiency and reducing emissions in the forging process. For example, some manufacturers are exploring the use of alternative energy sources, such as renewable energy, to power their forging operations.

2. Fluctuating Raw Material Costs and Availability

The cost and availability of raw materials, such as steel, aluminum, titanium, and nickel alloys, are critical factors that influence the metal forging market. These materials are essential for the forging process, and their prices are subject to various factors, including global supply and demand dynamics, geopolitical tensions, and environmental regulations.

Fluctuating raw material costs can lead to uncertainty in pricing and profitability for forging manufacturers. Additionally, disruptions in the supply chain, whether due to geopolitical issues or natural disasters, can further exacerbate the challenge of securing a steady supply of raw materials. For example, the COVID-19 pandemic highlighted the vulnerability of global supply chains, leading to shortages of critical materials and components.

To mitigate these risks, some forging companies are adopting strategies such as vertical integration, where they acquire or partner with raw material suppliers to secure a stable supply. Others are investing in research and development to create new materials or alloys that offer similar properties to traditional metals but are less susceptible to price fluctuations.

3. Environmental and Regulatory Challenges

The metal forging industry is subject to a range of environmental regulations aimed at reducing emissions, waste, and energy consumption. Compliance with these regulations can be costly and may require significant investments in new technologies and processes. For example, the European Union's Emissions Trading System (ETS) and the United States' Clean Air Act impose strict limits on industrial emissions, including those from metal forging operations.

In addition to regulatory pressures, there is growing demand from consumers and businesses for sustainable and environmentally friendly products. This trend is driving the industry to adopt more sustainable practices, such as recycling chunk metal, reducing waste, and improving energy efficiency. However, implementing these changes can be challenging, particularly for small and medium-sized enterprises (SMEs) that may lack the resources to invest in new technologies.

Opportunities for Growth in the Metal Forging Market

1. Adoption of Industry 4.0 Technologies

The metal forging industry is increasingly adopting Industry 4.0 technologies, such as automation, artificial intelligence (AI), and the Internet of Things (IoT), to enhance production efficiency, reduce waste, and improve product quality. These technologies offer significant opportunities for growth by enabling manufacturers to optimize their operations and respond more effectively to market demands.

For example, the use of AI in predictive maintenance can help identify potential equipment failures before they occur, reducing downtime and maintenance costs. Similarly, IoT-enabled devices can provide real-time data on the forging process, allowing manufacturers to monitor and adjust production parameters to improve efficiency and quality.

Another area where Industry 4.0 technologies are making an impact is in supply chain management. By leveraging data analytics and AI, forging companies can better predict demand, manage inventory, and optimize their supply chains. This can help reduce lead times, minimize waste, and improve customer satisfaction.

2. Advancements in Forging Technology

Advancements in forging technology are creating new opportunities for growth in the metal forging market. Traditional forging methods, such as open die and closed die forging, have been refined over the years to improve precision and reduce material waste. Additionally, newer techniques, such as cold forging and precision forging, are gaining popularity due to their ability to produce high-quality components with minimal post-processing.

Cold forging, in particular, is expected to register the highest CAGR during the forecast period. This method enhances the mechanical properties of the forged parts, such as strength, hardness, and durability, by inducing strain hardening and aligning the grain structure of the metal. As a result, cold-forged components are highly desirable for applications requiring superior mechanical performance, such as in the automotive and aerospace industries. The high-speed nature of cold forging also allows for rapid production, making it an attractive option for manufacturers looking to increase output while maintaining consistent quality.

Precision forging is another area of growth, offering the ability to produce complex shapes with tight tolerances and minimal waste. This method is particularly useful in industries where precision and performance are critical, such as aerospace, defense, and medical devices. As demand for high-performance components continues to grow, precision forging is expected to play an increasingly important role in the metal forging market.

3. Growth in Emerging Markets

Emerging markets, particularly in Asia-Pacific, Latin America, and Africa, offer significant opportunities for growth in the metal forging market. These regions are experiencing rapid industrialization, urbanization, and infrastructure development, driving demand for forged metal components.

For example, Asia-Pacific is expected to dominate the metal forging market, accounting for over 51.0% of the market share in 2024. Countries such as China, India, Japan, and South Korea are witnessing a boom in manufacturing and construction activities, creating a strong demand for forged components in industries such as automotive, aerospace, and construction.

In Latin America, countries like Brazil and Mexico are investing in infrastructure projects and expanding their industrial base, leading to increased demand for forged components. Similarly, in Africa, the growing energy and mining sectors are driving demand for high-performance forged components that can withstand harsh operating conditions.

As these emerging markets continue to develop, they offer substantial growth opportunities for forging companies that can establish a strong presence in the region. By investing in local production facilities, forging companies can tap into these markets and meet the rising demand for forged components.

4. Increasing Demand for Lightweight Materials

The demand for lightweight materials in various industries, particularly automotive and aerospace, is driving innovation in the metal forging market. Lightweight materials, such as aluminum, titanium, and magnesium alloys, are increasingly being used in forging applications due to their high strength-to-weight ratios and excellent mechanical properties.

In the automotive industry, the push for fuel efficiency and reduced emissions is leading manufacturers to adopt lightweight materials for key components such as engine parts, structural elements, and chassis components. Forged aluminum, for example, is widely used in the production of wheels, suspension systems, and engine components, offering the necessary strength and durability while reducing overall vehicle weight.

The aerospace industry is also a major consumer of lightweight forged components, particularly those made from titanium and aluminum alloys. These materials are used in critical applications such as aircraft engines, landing gear, and structural elements, where weight reduction is essential for improving fuel efficiency and performance.

As the demand for lightweight materials continues to grow, the metal forging market is expected to see increased adoption of these materials, driving further innovation and growth.

Customize Your Report : https://www.meticulousresearch.com/request-sample-report/cp_id=5879

Regional Insights: Asia-Pacific Leads the Way

The global metal forging market is segmented by region, with each region exhibiting distinct growth trends and opportunities.

Asia-Pacific: The Dominant Market

The Asia-Pacific region is expected to dominate the metal forging market, accounting for over 51.0% of the market share in 2024. The region's growth is driven by rapid industrialization, urbanization, and infrastructure development, particularly in countries such as China, India, Japan, and South Korea.

China is the largest market for metal forging in the region, driven by its massive manufacturing base and ongoing infrastructure projects. The country is home to a large number of forging companies, ranging from small and medium-sized enterprises to large multinational corporations. China's strong industrial base, coupled with government support for manufacturing and infrastructure development, is expected to drive continued growth in the metal forging market.

India is another key market in the region, with rapid urbanization and industrialization creating strong demand for forged components. The Indian government's focus on infrastructure development, such as the construction of roads, bridges, and power plants, is driving demand for forged metal components in the construction and energy sectors.

Japan and South Korea are also significant players in the Asia-Pacific metal forging market, with advanced manufacturing capabilities and a focus on high-performance applications in industries such as automotive and aerospace. Both countries have a strong tradition of innovation in forging technologies, making them leaders in the development of new materials and processes.

North America: A Strong Market with Technological Leadership

North America, including the United States and Canada, represents a significant market for metal forging, driven by strong demand from the automotive, aerospace, and defense industries. The region benefits from advanced manufacturing capabilities, technological innovation, and a well-established industrial base.

The United States is the largest market for metal forging in North America, with a strong focus on high-performance applications in aerospace and defense. The country is home to some of the world's leading forging companies, which are known for their expertise in producing complex, high-quality components for critical applications.

Canada is also a key market in the region, with a focus on automotive and industrial applications. The country's strong manufacturing base and access to raw materials make it an important player in the North American metal forging market.

Europe: A Market Focused on Quality and Precision

Europe is a key market for metal forging, with a focus on high-performance applications in aerospace, automotive, and industrial sectors. The region is characterized by its emphasis on quality and precision, supported by a strong manufacturing infrastructure and technological advancements.

Germany is the largest market for metal forging in Europe, driven by its strong automotive and industrial sectors. The country is known for its precision engineering and high-quality manufacturing, making it a leader in the production of forged components for critical applications.

The United Kingdom and France are also significant players in the European metal forging market, with a focus on aerospace and defense applications. Both countries have a strong tradition of innovation in forging technologies, particularly in the development of lightweight materials and advanced processes.

Latin America: Growth Driven by Infrastructure and Industrial Expansion

Latin America is experiencing growth in the metal forging market, driven by infrastructure development and industrial expansion. Countries such as Brazil and Mexico are key contributors to the region's growth, with increasing demand for forged components in construction, automotive, and energy sectors.

Brazil is the largest market for metal forging in Latin America, with a focus on infrastructure projects and industrial manufacturing. The country's growing energy sector, particularly in oil and gas exploration, is driving demand for high-performance forged components that can withstand harsh operating conditions.

Mexico is another key market in the region, with a strong focus on automotive manufacturing. The country's proximity to the United States, combined with its growing industrial base, makes it an important player in the North American supply chain for forged components.

Middle East & Africa: Growth Supported by Energy and Mining Sectors

The Middle East and Africa region is seeing growth in the metal forging market, supported by infrastructure projects, oil and gas exploration, and industrial development. The region's growth is driven by investments in construction, energy, and mining sectors.

The Middle East, particularly countries such as Saudi Arabia and the United Arab Emirates, is investing heavily in infrastructure development as part of their economic diversification efforts. These projects are driving demand for forged metal components in construction and energy applications.

Africa is also experiencing growth in the metal forging market, particularly in the mining sector. The continent's rich mineral resources and growing industrial base are creating demand for robust forged components that can withstand the rigors of mining operations.

Key Players: Leading Innovators Driving Market Growth

The metal forging market is characterized by the presence of several key players who are leading the industry through innovation and strategic initiatives. These companies are investing in research and development, technological advancements, and strategic partnerships to maintain their competitive edge.

Read Full Report @ https://www.meticulousresearch.com/product/metal-forging-market-5879

Leading Companies in the Metal Forging Market:

Arconic Corporation (U.S.): A global leader in lightweight metals engineering and manufacturing, Arconic is known for its innovative forging solutions and advanced materials used in aerospace, automotive, and industrial applications.

Nippon Steel Corporation (Japan): As one of the largest steel producers in the world, Nippon Steel provides a wide range of forged components for automotive, construction, and energy sectors, leveraging its expertise in steel manufacturing.

Precision Castparts Corp. (U.S.): Precision Castparts specializes in high-performance forgings for aerospace, defense, and industrial applications, known for its advanced materials and precision engineering.

Thyssenkrupp AG (Germany): Thyssenkrupp is a leading engineering company with a focus on producing high-quality forged components for automotive, aerospace, and industrial applications.

Bharat Forge Limited (India): Bharat Forge is one of the largest forging companies in the world, known for its expertise in producing complex, high-strength components for automotive and industrial applications.

Aubert & Duval (France): Aubert & Duval is a leading producer of high-performance forged components for aerospace, defense, and energy applications, known for its expertise in advanced materials and precision engineering.

Scot Forge (U.S.): Scot Forge is a leading open die forging company, specializing in producing large, complex components for heavy industry, including mining, oil and gas, and power generation.

Ellwood Group Incorporated (U.S.): Ellwood Group is a leading supplier of forged components for the aerospace, defense, and energy sectors, known for its advanced manufacturing capabilities and focus on quality.

Sumitomo Corporation (Japan): Sumitomo is a diversified industrial company with a strong presence in the metal forging market, producing high-quality forged components for automotive, aerospace, and industrial applications.

GKN Aerospace (U.K.): GKN Aerospace is a leading producer of high-performance forged components for the aerospace industry, known for its expertise in advanced materials and precision engineering.

These companies are at the forefront of innovation in the metal forging market, driving growth through technological advancements, strategic partnerships, and a focus on quality and performance.

Read Related Reports-

• Metal Powder Market : https://www.meticulousresearch.com/product/metal-powder-market-5860

• Aerospace and Defense Metal Stamping Market : https://www.meticulousresearch.com/product/aerospace-and-defense-metal-stamping-market-5103

• Metal Stamping Market : https://www.meticulousresearch.com/product/metal-stamping-market-4315

• South East Asia Galvanized Steel Market : https://www.meticulousresearch.com/product/south-east-asia-galvanized-steel-market-5019

• Galvanized Steel Market : https://www.meticulousresearch.com/product/galvanized-steel-market-5846

• Superabsorbent Polymers Market : https://www.meticulousresearch.com/product/superabsorbent-polymers-market-5525

• Silicone Elastomers Market : https://www.meticulousresearch.com/product/silicone-elastomers-market-5844

• Construction Equipment Market : https://www.meticulousresearch.com/product/construction-equipment-market-5847

• Cleanroom Technology Market : https://www.meticulousresearch.com/product/cleanroom-technology-market-5542

• Industrial Automation Software Market : https://www.meticulousresearch.com/product/industrial-automation-software-market-5279

Meticulous Market Research Inc.

21267 Willis St, Ste 200

Redding, California, 96001

United States of America

Entity (File) Number: C4705184

About Meticulous Research®

Meticulous Research® was founded in 2010 and incorporated as Meticulous Market Research Pvt. Ltd. in 2013 as a private limited company under the Companies Act, 1956. Since its incorporation, the company has become the leading provider of premium market intelligence in North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

The name of our company defines our services, strengths, and values. Since the inception, we have only thrived to research, analyze, and present the critical market data with great attention to details. With the meticulous primary and secondary research techniques, we have built strong capabilities in data collection, interpretation, and analysis of data including qualitative and quantitative research with the finest team of analysts. We design our meticulously analyzed intelligent and value-driven syndicate market research reports, custom studies, quick turnaround research, and consulting solutions to address business challenges of sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Forging Market Projected to Reach $153.9 Billion by 2031, Driven by Infrastructure Growth and Technological Innovations here

News-ID: 3644678 • Views: …

More Releases from Meticulous Research®

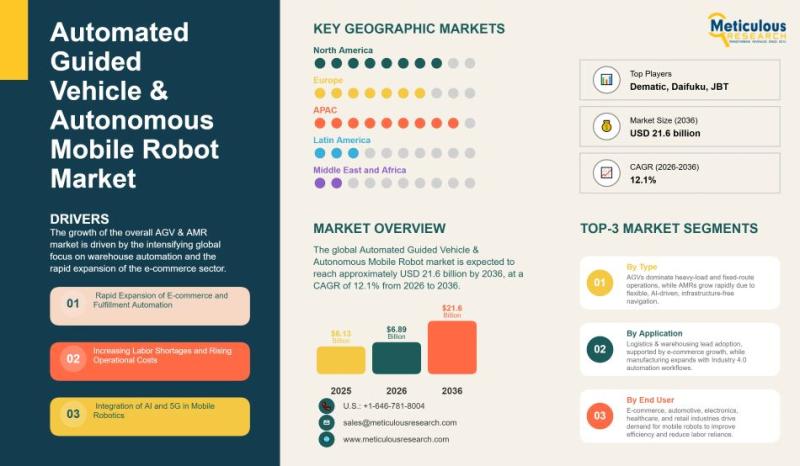

Global AGV & AMR Market Outlook 2026-2036: Trends, Growth, and Opportunities

The market for Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) is growing rapidly as industries around the world embrace automation. In 2025, the global market was valued at around USD 6.13 billion. By 2026, it is expected to reach USD 6.89 billion and could climb to USD 21.6 billion by 2036, growing at a healthy CAGR of 12.1%. This surge is largely fueled by the increasing need for…

Global Vanadium Flow Battery Market Forecast 2026-2036: Trends, Growth Drivers, …

The vanadium flow battery market is on the rise, largely because the world needs better ways to store renewable energy over long periods. Back in 2025, the market was valued at about USD 387.5 million, and by 2026 it is expected to reach roughly USD 468.1 million. Looking further ahead, by 2036, this market could touch USD 3 billion, growing at an impressive CAGR of 20.4% from 2026 to 2036.…

Automotive Intrusion Detection and Prevention Systems (IDPS) Market: Global Outl …

The global automotive intrusion detection and prevention systems (IDPS) market is projected to reach USD 7.82 billion by 2036, up from USD 1.53 billion in 2026, reflecting a robust compound annual growth rate (CAGR) of 17.9% over the forecast period. Automotive IDPS are specialized cybersecurity solutions designed to monitor vehicle networks, detect malicious activities or unusual behavior, and respond in real time to mitigate cyber threats. These systems protect connected,…

Functional Safety Microcontrollers (MCUs) Market: Global Outlook, Growth Trends, …

The global functional safety microcontrollers (MCUs) market is experiencing strong and sustained growth, driven by the rising complexity of automotive electronics and increasingly strict vehicle safety requirements. The market is projected to expand from a value of USD 4.92 billion in 2026 to USD 14.73 billion by 2036, registering a compound annual growth rate (CAGR) of 11.6% over the forecast period. This growth reflects the essential role functional safety MCUs…

More Releases for America

Stabilit America Highlights Applications of Fiberglass Roof Panels with Stabilit …

Roofing materials are very important in the realm of modern construction, as they should be long lasting, economical and attractive. Fiberglass roof panels are a few of the numerous choices among several alternatives that have received a reputation of being versatile, long life, and adaptable in various sectors. They are favored by the architects, contractors, and property developers due to their lightweight construction, resistance to weather factors, and the ease…

Deodorants Market Report by Region (North America, EMEA, Latin America, Asia)

2025 - Pristine Market Insights, a leading market research firm, announced the release of its latest and comprehensive market research report on Deodorants market. The report spans over 500 pages and delivers 10-year market forecast in US dollars (or custom currencies upon request). It provides in-depth analysis of market dynamics (drivers, opportunities, restraints), PESTLE insights, latest industry trends, and demand factors. The report includes segmented market value, share (%), compound…

Sequestrant Market Report by Region (North America, EMEA, Latin America, Asia)

2025 - Pristine Market Insights, a leading market research firm, announced the release of its latest and comprehensive market research report on Sequestrant market. The report spans over 500 pages and delivers 10-year market forecast in US dollars (or custom currencies upon request). It provides in-depth analysis of market dynamics (drivers, opportunities, restraints), PESTLE insights, latest industry trends, and demand factors. The report includes segmented market value, share (%), compound…

Buttermilk Market Study by Region (North America, Latin America, Europe, Asia, M …

2025 - Pristine Market Insights, a leading market research firm, announced the release of its latest and comprehensive market research report on Buttermilk market. The report spans over 500 pages and delivers 10-year market forecast in US dollars (or custom currencies upon request). It provides in-depth analysis of market dynamics (drivers, opportunities, restraints), PESTLE insights, latest industry trends, and demand factors. The report includes segmented market value, share (%),…

Textiles Market Analysis Report, Regional Outlook - Europe, North America, South …

Adroit Market Research has announced the addition of the “Global Textiles Market Size Status and Forecast 2025”, The report classifies the global Textiles in a precise manner to offer detailed insights about the aspects responsible for augmenting as well as restraining market growth.

This report studies the global Textiles Speaker market, analyzes and researches the Textiles Speaker development status and forecast in Europe, North America, Central America, South America, Asia Pacific…

Global Gaucher Disease Market 2018 Covering North America, South America, Europe

Gaucher Disease Market

Summary

The Global Gaucher Disease Market is defined by the presence of some of the leading competitors operating in the market, including the well-established players and new entrants, and the suppliers, vendors, and distributors. The key players are continuously focusing on expanding their geographic reach and broadening their customer base, in order to expand their product portfolio and come up with new advancements.

Gaucher Disease market size to maintain the average annual growth…