Press release

Metal Fabrication Equipment Market Poised for Significant Growth: Forecast to Reach Around USD 103 Billion by 2032

Metal Fabrication Equipment Market Size and Growth:The Metal Fabrication Equipment Market Size, valued at approximately USD 67.2 Billion in 2023, is projected to witness substantial growth. By 2032, the market is expected to reach an impressive USD 102.7 Billion, growing at a robust CAGR of 4.9% from 2024 to 2032. This growth trajectory underscores the escalating demand and the pivotal role metal fabrication equipment plays in modern manufacturing and construction.

Key Market Drivers:

Technological Advancements

One of the primary drivers propelling the Metal Fabrication Equipment Market forward is the rapid pace of technological advancements. Innovations such as CNC (Computer Numerical Control) machines, laser cutting technologies, and advanced welding techniques are revolutionizing the industry, enhancing precision, and efficiency. These technologies are not only improving the quality of metal fabrication but also reducing production costs, thereby attracting more investment and interest in the market.

-------------------------------------------------------------------------------------------------------------------

REQUEST A $1000 DISCOUNT ON CREDIT CARD PURCHASE: https://www.acumenresearchandconsulting.com/inquiry-before-buying/939

-------------------------------------------------------------------------------------------------------------------

Increasing Demand Across Industries:

The demand for metal fabrication equipment is significantly influenced by various industry sectors.

Automotive Industry

The automotive sector is a major contributor to the demand for metal fabrication equipment. With the continuous push towards more efficient and sustainable vehicles, automakers are increasingly relying on advanced fabrication technologies to produce high-quality components and structures. The need for lightweight materials and complex geometries in modern vehicles further drives the adoption of sophisticated metal fabrication equipment.

Aerospace Sector

Similarly, the aerospace industry benefits immensely from advanced metal fabrication equipment. The requirement for precision-engineered components that meet stringent safety and performance standards necessitates the use of cutting-edge fabrication technologies. As the aerospace sector grows, so does the demand for high-performance metal fabrication solutions.

Growing Infrastructure Projects

The expansion of infrastructure projects worldwide also fuels the growth of the metal fabrication equipment market. From bridges and highways to commercial and residential buildings, the need for robust and durable metal structures is on the rise. This trend supports the market's expansion as construction firms invest in state-of-the-art fabrication equipment to meet the increasing demands of infrastructure development.

Download Sample Report Copy of This Report from Here: https://www.acumenresearchandconsulting.com/request-sample/939

Metal Fabrication Equipment Market Trends:

Automation and Robotics

Automation and robotics are at the forefront of trends shaping the Metal Fabrication Equipment Market. The integration of automated systems into fabrication processes enhances productivity, accuracy, and consistency. Robotic arms and automated welding systems are becoming standard in metal fabrication facilities, enabling manufacturers to streamline operations and reduce human error.

Sustainable Practices

Sustainability is becoming a central focus in the metal fabrication industry. Companies are adopting energy-efficient technologies and recycling practices to minimize their environmental impact.

Energy-Efficient Technologies

Energy-efficient technologies are crucial in reducing operational costs and conserving resources. Metal fabrication equipment manufacturers are investing in innovations that reduce energy consumption and improve overall efficiency.

Recycling and Waste Management

Recycling and waste management practices are also gaining traction. The industry is exploring ways to repurpose reduce waste, aligning with global sustainability goals.

Integration of IoT and AI

The Internet of Things (IoT) and Artificial Intelligence (AI) are revolutionizing the metal fabrication landscape. IoT devices enable real-time monitoring and control of fabrication processes, while AI algorithms optimize production schedules and maintenance. This integration enhances operational efficiency and provides valuable insights for decision-making.

Competitive Landscape:

Major Players in the Market

The Metal Fabrication Equipment Market is highly competitive, with several key players dominating the landscape. Companies such as Trumpf, Amada Co., Ltd., and DMG Mori are leading the market, offering a range of advanced metal fabrication solutions.

Market Share Analysis

Metal Fabrication Equipment Market share analysis reveals a dynamic competition among established players and emerging companies. Leading firms are focusing on strategic acquisitions, partnerships, and innovations to maintain their competitive edge.

Leading Companies

Leading companies are continuously evolving their product portfolios to meet the changing needs of the metal fabrication equipment market industry. They invest in research and development to introduce cutting-edge technologies and maintain market leadership.

Emerging Players

Emerging players are also making their mark by introducing novel solutions and catering to niche segments within the market. Their agility and innovative approaches contribute to the overall metal fabrication equipment market growth and diversity.

Strategic Initiatives

Strategic initiatives such as mergers and acquisitions, collaborations, and technology partnerships are shaping the competitive landscape. These moves enable companies to expand their market presence and enhance their product offerings.

Regional Analysis:

North America

In North America, the metal fabrication equipment market is driven by technological advancements and a strong manufacturing base. The region's focus on automation and innovation supports its market growth.

Europe

Europe exhibits significant market potential due to its emphasis on sustainable practices and advanced manufacturing technologies. The region's stringent regulations and environmental standards are encouraging investments in energy-efficient fabrication solutions.

Asia-Pacific

The Asia-Pacific region is witnessing rapid industrialization and infrastructure development, driving demand for metal fabrication equipment. Countries such as China and India are major contributors to the market's expansion in this region.

Rest of the World

The Rest of the World region, including Latin America and the Middle East, is experiencing steady growth in the metal fabrication equipment market. Increasing construction activities and industrialization are key factors driving market expansion in these areas.

Challenges and Opportunities:

Supply Chain Constraints

Supply chain constraints pose challenges to the metal fabrication equipment market. Issues such as raw material shortages and logistical delays can impact production timelines and costs.

Technological Barriers

Technological barriers, including the high initial investment required for advanced equipment, can also hinder market growth. However, ongoing technological advancements are gradually addressing these challenges.

Opportunities for Innovation

Despite these challenges, there are significant opportunities for innovation. Companies that invest in research and development and explore new technologies can capitalize on emerging market trends and gain a competitive advantage.

Future Outlook:

Long-term Market Projections

The long-term outlook for the metal fabrication equipment market is positive, with sustained growth expected. Technological advancements, increased industrial activities, and rising demand for advanced fabrication solutions will continue to drive market expansion.

Potential Market Shifts

Potential market shifts may include the adoption of new materials and fabrication techniques, as well as changes in industry regulations and consumer preferences. Staying abreast of these shifts will be crucial for market players to remain competitive.

Conclusion:

In summary, the Metal Fabrication Equipment Market is poised for substantial growth, driven by technological advancements, increasing industrial demand, and evolving market trends. Acumen Research and Consulting's report provides valuable insights into the market's dynamics, competitive landscape, and future prospects. Businesses and stakeholders can leverage this information to make informed decisions and capitalize on emerging opportunities within the metal fabrication sector.

Ask Query Here: Richard@acumenresearchandconsulting.com or sales@acumenresearchandconsulting.com

Click here to get more information about this Report: https://www.acumenresearchandconsulting.com/metal-fabrication-equipment-market

FAQs:

What is the current size of the Metal Fabrication Equipment Market?

The Metal Fabrication Equipment Market Size was USD 67.2 Billion in 2023 and is expected to grow to USD 102.7 Billion by 2032, reflecting a CAGR of 4.9% from 2024 to 2032.

What factors are driving growth in the Metal Fabrication Equipment Market?

Several factors contribute to the growth of the Metal Fabrication Equipment Market, including technological advancements in fabrication processes, increasing demand across various industries such as automotive and aerospace, and the expansion of infrastructure projects globally. The integration of automation, robotics, IoT, and AI into metal fabrication is also a significant driver.

Who are the major players in the Metal Fabrication Equipment Market?

Major players in the Metal Fabrication Equipment Market include Trumpf, Amada Co., Ltd., DMG Mori, and other key companies. These companies dominate the market by offering advanced fabrication solutions and continuously innovating their product lines. Emerging players are also making significant contributions by catering to specific niches and introducing new technologies.

What are the key trends in the Metal Fabrication Equipment Market?

Key trends in the Metal Fabrication Equipment Market include the increasing adoption of automation and robotics, a focus on sustainable practices like energy-efficient technologies and recycling, and the integration of IoT and AI for improved operational efficiency. These trends are shaping the future of metal fabrication by enhancing productivity and reducing environmental impact.

What is the forecast for the Metal Fabrication Equipment Market?

The Metal Fabrication Equipment Market is forecasted to experience substantial growth, reaching USD 102.7 Billion by 2032. This growth is driven by ongoing technological advancements, the rising demand from various industrial sectors, and the adoption of sustainable and automated fabrication practices. The market is expected to continue evolving with innovations in materials, processes, and technologies.

To Purchase this Premium Report@ https://www.acumenresearchandconsulting.com/buy-now/0/939

201, Vaidehi-Saaket, Baner - Pashan Link Rd, Pashan, Pune, Maharashtra 411021

Acumen Research and Consulting (ARC) is a global provider of market intelligence and consulting services to information technology, investment, telecommunication, manufacturing, and consumer technology markets. ARC helps investment communities, IT professionals, and business executives to make fact based decisions on technology purchases and develop firm growth strategies to sustain market competition. With the team size of 100+ Analysts and collective industry experience of more than 200 years, Acumen Research and Consulting assures to deliver a combination of industry knowledge along with global and country level expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Fabrication Equipment Market Poised for Significant Growth: Forecast to Reach Around USD 103 Billion by 2032 here

News-ID: 3631638 • Views: …

More Releases from Acumen Research and Consulting

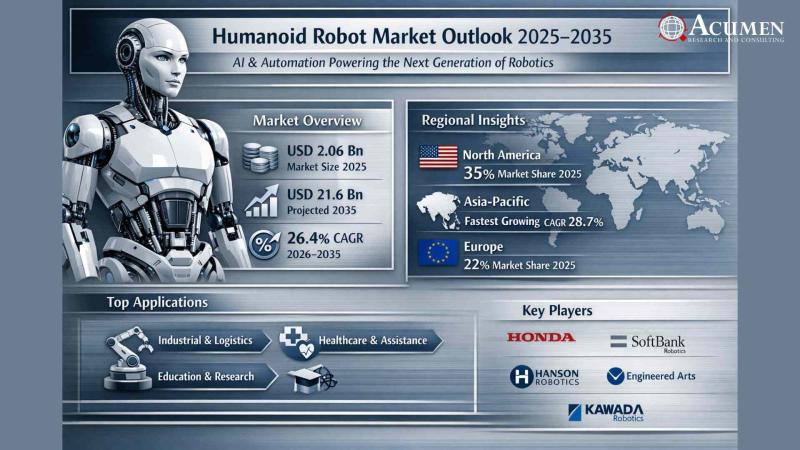

Humanoid Robot Market to Reach USD 21.6 Billion by 2035 | AI & Automation Drive …

Humanoid Robot Market to Surpass USD 21.6 Billion by 2035: AI-Driven Automation Unlocks a New Era of Human-Machine Collaboration

The Humanoid Robot Market is undergoing a transformative boom, reflecting a seismic shift in how industries leverage robotics, artificial intelligence (AI), and automation to meet the growing demands of a rapidly evolving global economy.

According to Acumen Research and Consulting, the global Humanoid Robot Market is projected to grow from USD 2,060.4 million…

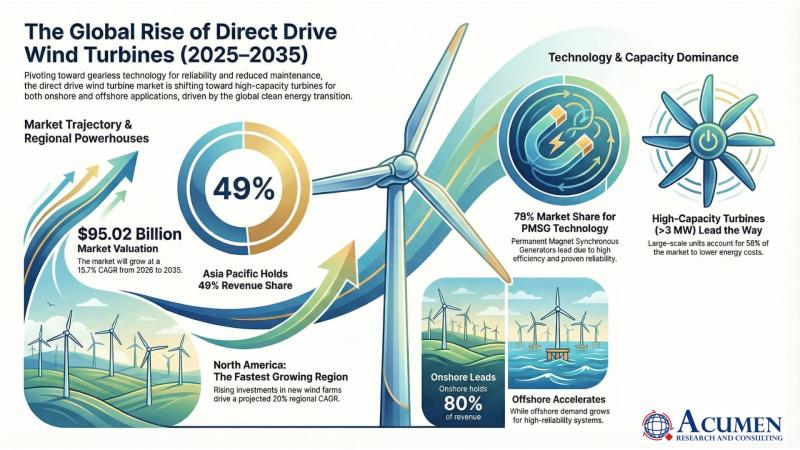

Direct Drive Wind Turbine Market to Reach USD 95.02 Billion by 2035 | Acumen Res …

Direct Drive Wind Turbine Market to Reach USD 95.02 Billion by 2035, Driven by Global Renewable Expansion and Offshore Innovation | Acumen Research and Consulting

The Direct Drive Wind Turbine Market is witnessing unprecedented growth momentum as the global renewable energy transition accelerates. According to a new report by Acumen Research and Consulting, the global Direct Drive Wind Turbine Market size is projected to grow from USD 21.91 billion in 2025…

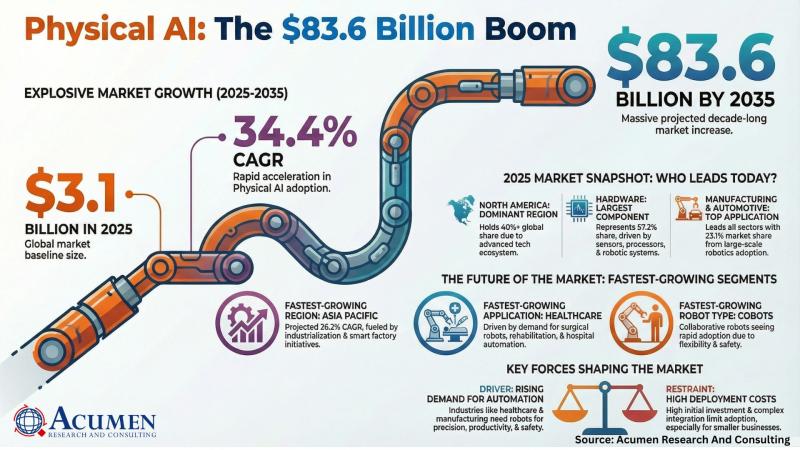

Physical AI Market Set to Surge to USD 83,642.5 Million by 2035 - Groundbreaking …

Global Physical AI Market Report 2026-2035: Robust Growth, Transformational Trends, and Unmatched Opportunities

The Physical AI Market is on the brink of remarkable expansion with groundbreaking advancements in artificial intelligence systems that interact intelligently with the physical world. According to a new market study by Acumen Research and Consulting, the global physical AI market is projected to grow from USD 3,137.5 Million in 2025 to USD 83,642.5 Million by 2035, exhibiting…

Semiconductor Packaging Market to Double from USD 44.21 Billion in 2024 to USD 1 …

Acumen Research And Consulting announces the release of its latest industry report highlighting the robust growth of the Semiconductor Packaging Market. The report reveals that the global market, valued at USD 44.21 billion in 2024, is projected to reach USD 104.76 billion by 2033, expanding at a steady Compound Annual Growth Rate (CAGR) of 10.1% between 2025 and 2033. This rapid growth underscores the increasing importance of packaging innovations in…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…