Press release

A Solution for Controlled Coefficient of Friction in Cast Polypropylene Films

Daily necessities like food and household items are indispensable in people's daily lives. As the pace of life continues to accelerate, various packaged foods and daily necessities have filled supermarkets and shopping malls, making it convenient for people to purchase, store, and use these items. Packaging materials play a crucial role in this convenience. With the continuous development of the packaging industry, automatic packaging production lines are being increasingly used in the production of food and daily necessities. As the speed and automation of packaging machines continue to increase, quality issues have also become prominent. Problems such as film breakage, slippage, production line interruptions, and package leaks are becoming more frequent, causing significant losses to many flexible packaging material manufacturers and printing companies. The main reason lies in the inability to control the friction and heat sealing properties of the automatic packaging films.Currently, the automatic packaging films on the market have the following main shortcomings:

* The outer layer of the packaging film has a low coefficient of friction (COF), while the inner layer has a high COF, causing slippage during the film run on the packaging line.

* The packaging film performs well at low temperatures but experiences issues at higher temperatures during the automatic packaging process.

* The low COF of the inner layer prevents proper positioning of the contents within the packaging film, leading to sealing failures when the heat seal strip presses on the contents.

* The packaging film performs well at low speeds but experiences poor heat sealing and leakage issues as the packaging line speed increases.

Do you understand the COF of automatic packaging film? Common anti-blocking and slip agents and challenges

The COF measures the sliding characteristics of packaging materials. The film's surface smoothness and appropriate COF are critical for the film packaging process, with different packaging material products having varying COF requirements. In actual packaging processes, friction can act as both a driving and a resisting force, necessitating effective control of the COF within an appropriate range. Generally, automatic packaging films require a relatively low COF for the inner layer and a moderate COF for the outer layer. If the inner layer COF is too low, it may cause instability and misalignment during bag forming. Conversely, if the outer layer COF is too high, it can cause excessive resistance during packaging, leading to material deformation, while too low COF can result in slippage, causing tracking and cutting inaccuracies.

The COF of composite films is influenced by the content of anti-blocking and slip agents in the inner layer, as well as the film's stiffness and smoothness. Currently, the slip agents used in inner layers are typically fatty acid amide compounds (such as primary amides, secondary amides, and bisamides). These materials are not fully soluble in polymers and tend to migrate to the film surface, reducing surface friction. However, the migration of amide slip agents in polymer films is affected by various factors, including slip agent concentration, film thickness, resin type, winding tension, storage environment, downstream processing, usage conditions, and other additives, making it difficult to ensure stable COF. Moreover, as more polymers are processed at higher temperatures, the thermal oxidative stability of slip agents becomes increasingly important. Oxidative degradation can lead to a loss of slip agent performance, discoloration, and odor.

The most common slip agents used in polyolefins are long-chain fatty acid amides, from oleamide to erucamide. The effectiveness of slip agents is due to their ability to precipitate on the film surface after extrusion. Different slip agents exhibit different rates of surface precipitation and COF reduction. As amide slip agents are low-molecular-weight migratory slip agents, their migration within the film is influenced by various factors, resulting in unstable COF. In solventless lamination processes, excessive amide slip agents in the film can cause heat sealing performance issues, commonly referred to as "blocking." The mechanism involves the migration of free isocyanate monomers in the adhesive to the film surface, reacting with the amide to form urea. Due to the high melting point of urea, this results in reduced heat sealing performance of the laminated film.

Novel non-migratory super slip & Anti-blocking agent [https://www.siliketech.com/super-slip-masterbatch/]

To address these issues, SILIKE has launched Non-precipitating Super-slip & Anti-blocking Masterbatch Additive [https://www.siliketech.com/silimer-series-super-slip-masterbatch/] - part of the SILIMER series. These modified polysiloxane products contain active organic functional groups. Their molecules include both polysiloxane chain segments and long carbon chains with active groups. The long carbon chains of active functional groups can physically or chemically bond with the base resin, anchoring the molecules and achieving easy migration without precipitation. The polysiloxane chain segments on the surface provide a smoothing effect.

Specifically, SILIMER 5065HB is designed for CPP films, and SILIMER 5064MB1 is suitable for PE-blown films and composite packaging bags. The advantages of these products include:

* SILIMER 5065HB and SILIMER 5064MB1 offer excellent anti-blocking and smoothness, resulting in a lower COF.

* SILIMER 5065HB and SILIMER 5064MB1 provide stable and permanent slip performance over time and under high-temperature conditions, without affecting printing, heat sealing, transmittance, or haze.

* SILIMER 5065HB and SILIMER 5064MB1 eliminate white powder precipitation, ensuring the integrity and aesthetics of the packaging.

*

SILIKE's SILIMER non-Blooming slip agent series provide an excellent solution for controlling the COF of automatic packaging films, from Cast Polypropylene Films, PE-blown films to Various multiple composite functional films. By addressing the migration issues of traditional slip agents and significantly improving the performance and appearance of packaging films, SILIKE offers a reliable choice for flexible packaging material manufacturers and printing companies.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn

website: www.siliketech.com to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=a-solution-for-controlled-coefficient-of-friction-in-cast-polypropylene-films]

Country: China

Website: https://www.siliketech.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A Solution for Controlled Coefficient of Friction in Cast Polypropylene Films here

News-ID: 3593184 • Views: …

More Releases from ABNewswire

This $6 AI Leprechaun Video Is Replacing the St. Patrick's Day Card as the Funni …

LeprechaunVideo.com launches an AI-powered video greeting service that transforms any selfie into a personalized talking leprechaun with an Irish accent, original comedy script and Celtic music for $5.99 - positioning itself as the modern alternative to the traditional St. Patrick's Day card.

BATH, England - Feb 23, 2026 - LeprechaunVideo.com today launched an AI-powered video greeting service that transforms a selfie into a personalized talking leprechaun, giving anyone a funnier way…

Sure Way Cash introduces online loan service for installment loans up to $10,000

Chicago, IL - Sure Way Cash [https://www.surewaycash.com/] today announced the launch of its online loan connector service that allows U.S. residents to check installment loan options up to $10,000 through a secure request process without a hard credit check.

The platform is designed for borrowers who may have bad credit, limited credit history, or prior loan denials and want to explore loan options without upfront fees or obligation. Users can submit…

Otter Public Relations Awarded in the Excellence in Workplace Culture Award for …

ST. PETERSBURG, Fla. - Feb 23, 2026 - Otter Public Relations [https://otterpr.com/]was proudly awarded Excellence in Workplace Culture for Small Businesses for 2025.

Otter PR, founded by Scott Bartnick and Jay Feldman, is one of the nation's most highly rated and awarded PR firms. With over 300 years of combined experience, Otter PR is known for results-driven campaigns and securing valuable media coverage. Otter PR's team of publicists, writers, marketers, and…

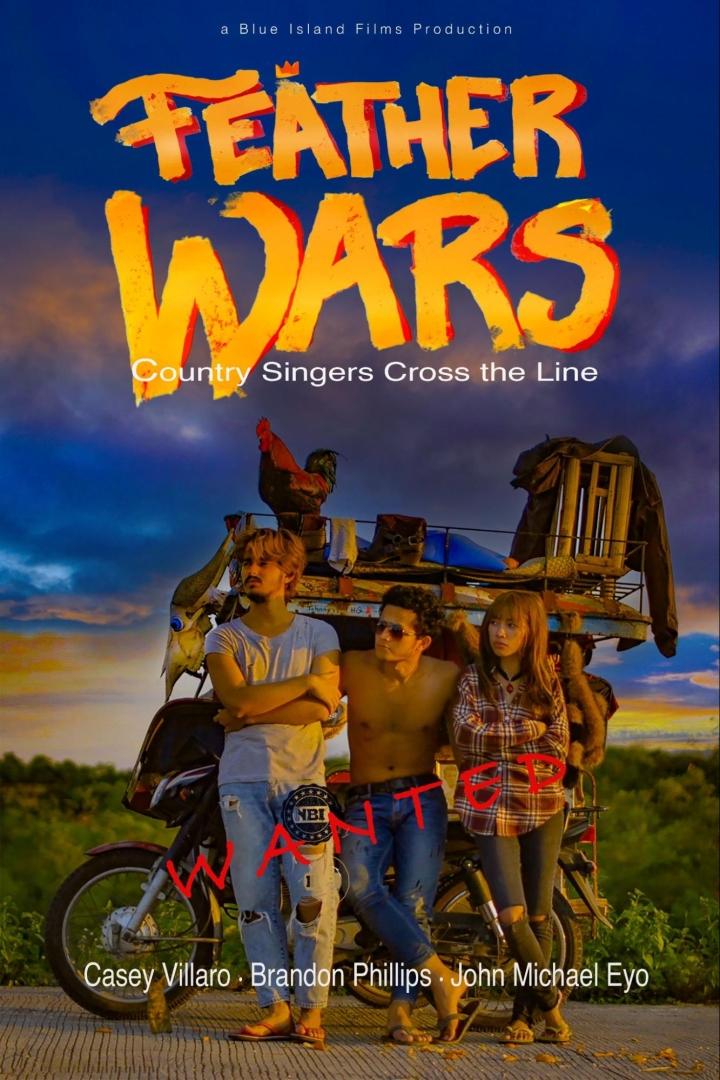

Philippine Coming-of-Age Film "Feather Wars" (2025) Wraps Production in Bohol, S …

Feather Wars is a 140-minute Filipino coming-of-age adventure comedy filmed in Bohol. Directed by Tim Fitzharris and produced by Jesse Fitzharris, it follows two teen musicians fleeing their abusive stepfather, funding their escape through underground cockfighting scams. Blending dark comedy, music, and family drama, the film highlights Filipino culture and earned international screenplay recognition before completing production in 2025.

BOHOL, PHILIPPINES - The Philippine independent film Feather Wars, a 140-minute coming-of-age…

More Releases for COF

COF Flexible Encapsulation Substrate Market Dynamics: Emerging Trends and Innova …

COF Flexible Encapsulation Substrate Market size was valued at USD 1.5 Billion in 2024 and is projected to reach USD 4.2 Billion by 2033, exhibiting a CAGR of 12.3% from 2026 to 2033.

COF Flexible Encapsulation Substrate Market Future Scope

The COF Flexible Encapsulation Substrate Market was valued at approximately USD 950 million in 2022, and it is projected to grow at a compound annual growth rate (CAGR) of 8.2% from 2023…

Global COB-COF Compact Camera Module Market Insights, Forecast to 2029

Global Info Research announces the release of the report "Global COB-COF Compact Camera Module Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . This report is a detailed and comprehensive analysis of the global market, with a particular focus on future projections. The report is structured into various segments, each analyzing the competition, supply and demand trends, as well as key factors that contribute to its changing demands…

Global Chip Packaging COF Substrate Market Research Report 2023-2029

The chip packaging COF substrate is the key to the current screen transformation. The main principle is to put the display driver IC chip into the flexible FPC cable, and then use the characteristics of the FPC itself to fold it to the bottom of the screen. Specifically, through thermocompression bonding, the gold bumps of the IC chip and the inner pins on the flexible substrate circuit will be combined.…

Chip On Flex (COF) Market to See Revolutionary Growth (2023-2029)

The Latest research study released by HTF MI "Global Chip On Flex (COF) Market with 101+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint and status (2023-2029). The market Study is segmented by key a region that is accelerating the marketization. Understanding the segments helps in identifying the importance…

Chip On Film Underfill (COF) Market 2021 | Detailed Report

Global Chip On Film Underfill (COF) Market 2021-2027, has been prepared based on an in-depth market analysis with inputs from industry experts. The report covers the market landscape and its growth prospects in the coming years. The report includes a discussion of the key vendors operating in this market. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC,…

Chip On Flex (COF) Market: Competitive Dynamics & Global Outlook 2023

New report published by Market Research Report Store (MRRS) which offers insights on the global Chip On Flex (COF) market.

Chip-on-Flex, or COF, refers to the semiconductor assembly technology wherein the microchip or die is directly mounted on and electrically connected to a flexible circuit (a circuit built on a flexible substrate instead of the usual printed circuit board). Thus, in a COF assembly, the microchip doesn't have to go through…