Press release

Global Silicone Resins Market: Forecasted Growth to Exceed US$ 1.5 Billion by 2032

The global silicone resins market is estimated at US$ 906.8 million in 2022 and is forecast to surpass US$ 1.5 billion by 2032, progressing at a steady CAGR of 5.1% from 2022 to 2032.Demand for liquid silicone resins is expected to increase a CAGR of 5.5% over the forecast period and reach a market size of US$ 783 million by the end of 2032.Silicone resins, a versatile class of synthetic polymers, have been witnessing substantial growth in demand due to their exceptional properties and wide-ranging applications. These resins are formed through the hydrolysis and polycondensation of silanes, resulting in a three-dimensional network structure with silicon-oxygen bonds. The silicone resins market has experienced significant expansion over the years, fueled by advancements in technology, increasing industrialization, and the growing demand for high-performance materials. In this article, we will explore the key factors driving the silicone resins market's growth, the various applications across industries, and the emerging trends that are shaping the industry's future.

Get a FREE Sample Copy of the Report (Including TOC, List of Tables & Figures, and Chart):https://www.factmr.com/connectus/sample?flag=S&rep_id=7539?AG

Market Drivers

Industrial Growth: The rapid industrialization across the globe has led to an increased demand for high-performance materials that can withstand extreme conditions and offer superior durability. Silicone resins possess excellent resistance to heat, chemicals, UV radiation, and weathering, making them ideal for a wide range of industrial applications, including coatings, adhesives, and electrical insulators.

Electronics and Electrical Industry: The electronics and electrical industry represents one of the most significant end-users for silicone resins. As electronic components become more compact and sophisticated, the need for advanced materials to protect and insulate these components has grown. Silicone resins provide outstanding electrical insulation properties, ensuring the reliability and longevity of electronic devices, thus driving their demand in this sector.

Automotive Sector: With an increasing emphasis on energy efficiency and lightweighting in the automotive industry, silicone resins have gained popularity as an ideal material for high-temperature-resistant coatings and adhesives in engine parts, exhaust systems, and automotive electronics. Moreover, these resins contribute to enhanced performance, reduced emissions, and improved safety, further boosting their adoption in the automotive sector.

Construction Industry: Silicone resins find extensive usage in the construction industry, primarily in high-performance architectural coatings, weatherproofing, and structural glazing applications. The increasing focus on sustainable construction materials with enhanced durability has propelled the demand for silicone resins in this sector.

Key Players and Competitive Landscape

Dow Chemicals

Elkem Silicones

Evonik

Innospec Inc.

Iota Silicone Oil (Anhui) Co. Ltd.

Kaneka

KCC Corporation

Shin-Etsu

Siltech Corporation

Wacker

Applications Across Industries

Coatings and Paints: Silicone resins are widely employed as binders in high-temperature-resistant coatings and paints due to their ability to maintain their properties under extreme conditions. They are extensively used in industrial equipment, aerospace, automotive components, and architectural structures, providing protection against corrosion, heat, and chemicals.

Adhesives and Sealants: The excellent adhesive properties of silicone resins make them valuable in various applications, including aerospace assembly, electronic component bonding, and automotive assembly. Additionally, they find use in sealants for building structures and industrial applications due to their strong bonding capabilities and weather resistance.

Electrical and Electronic Components: The electrical and electronic industry relies heavily on silicone resins to encapsulate and protect sensitive components. The resins offer excellent electrical insulation and thermal stability, safeguarding electronic devices from moisture, contaminants, and mechanical stress.

Mold Making and Casting: Silicone resins are popular for mold making in various industries, including arts and crafts, manufacturing, and prototyping. Their ability to capture intricate details and release the molded product easily makes them ideal for these applications.

Textile Coatings: In the textile industry, silicone resins are utilized for imparting water repellency, softness, and wrinkle resistance to fabrics. These coatings enhance the performance and durability of textiles, making them suitable for outdoor apparel, sportswear, and medical textiles.

Emerging Trends

Bio-based Silicone Resins: The shift towards sustainable materials has led to the development of bio-based silicone resins derived from renewable sources. These eco-friendly alternatives are expected to gain prominence as environmental concerns drive industry innovations.

Nanotechnology Integration: Researchers are exploring the incorporation of nanotechnology into silicone resins to enhance their mechanical and thermal properties. Nanoscale additives can improve the resins' performance, making them more versatile and suitable for advanced applications.

3D Printing Applications: Silicone resins are finding new horizons in the field of additive manufacturing, particularly in 3D printing. The ability to print complex structures with silicone resins opens up possibilities in customized medical devices, electronics, and consumer products.

Get Customization on this Report for Specific Research Solutions:https://www.factmr.com/connectus/sample?flag=RC&rep_id=7539?AG

US Sales Office:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E-Mail: sales@factmr.com

About Us -

Fact.MR addresses this challenge head-on by providing insights (not data) that are easy to understand and execute. A leading provider of syndicated and custom market research reports, we offer cutting-edge business intelligence to clients from a range of industries.Our research team is highly qualified to help organizations with their market research needs. In a world where constant disruption is the norm rather than the exception, Fact.MR identifies opportunities and challenges early, and provides its clients the foundation for a winning strategy.We provide both qualitative and quantitative research, spanning market forecast, market segmentation, competitor analysis, and consumer sentiment analysis

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Silicone Resins Market: Forecasted Growth to Exceed US$ 1.5 Billion by 2032 here

News-ID: 3581913 • Views: …

More Releases from FactMR

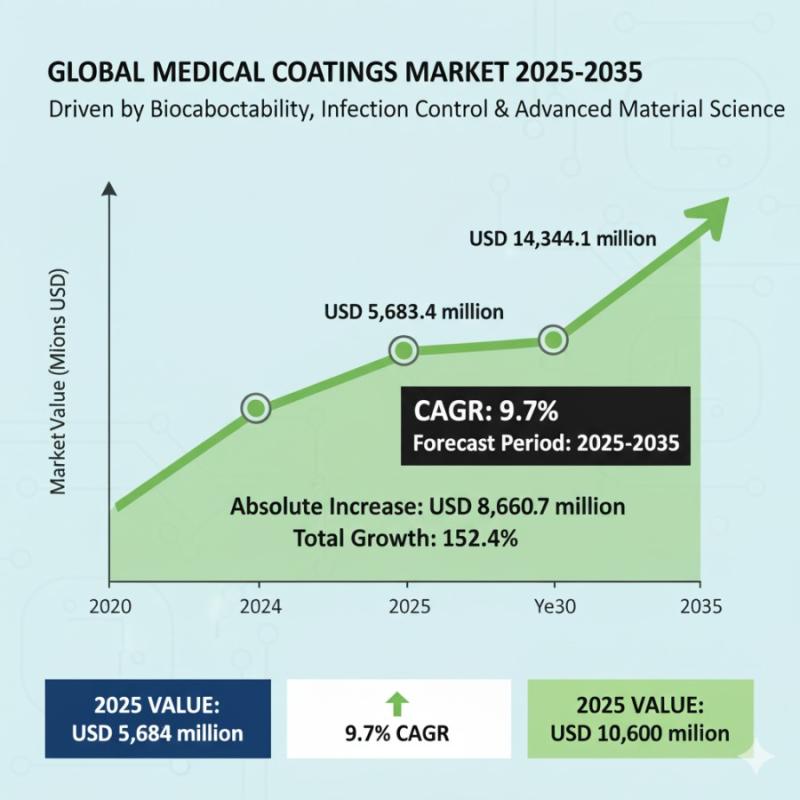

Medical Coatings Market to Hit USD 14,344.1 million by 2035- Growth Accelerates …

The global medical coatings market is set for sustained growth through 2035, powered by minimally invasive procedures, infection prevention priorities, and smart biocompatible innovations. According to Future Market Insights (FMI), the market is valued at USD 5,683.4 million in 2025 and is projected to reach USD 14,344.1 million by 2035, expanding at a compound annual growth rate (CAGR) of 9.7%.

The FMI report, "Medical Coatings Market Size, Share, and Forecast 2025-2035,"…

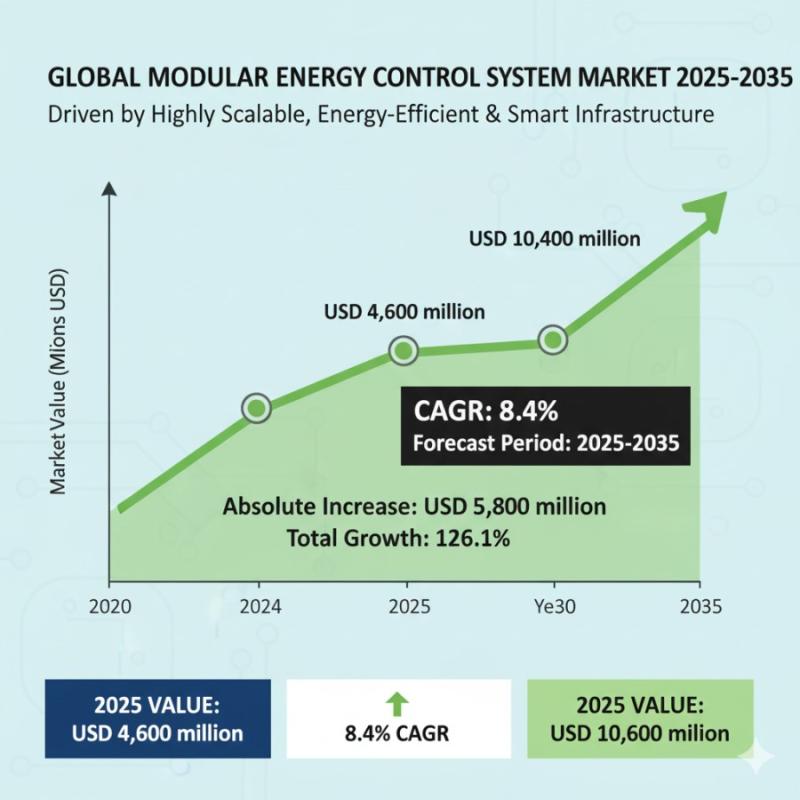

Modular Energy Control System Market to Hit USD 10,400 million by 2035- Growth A …

The global modular energy control system market is set for robust expansion through 2035, fueled by scalable infrastructure, real-time optimization, and seamless renewable energy integration. According to Future Market Insights (FMI), the market is valued at USD 4,600 million in 2025 and is projected to reach USD 10,400 million by 2035, expanding at a compound annual growth rate (CAGR) of 8.4%

The FMI report, "Modular Energy Control System Market Size, Share,…

Airborne Warning and Control System Market to Surpass USD 11,888.1 million by 20 …

The global airborne warning and control system (AWACS) market is accelerating toward a decade of robust expansion, driven by escalating geopolitical tensions, defense modernization, and AI-enhanced threat detection. According to Future Market Insights (FMI), the market is valued at USD 5,209.7 million in 2025 and is projected to reach USD 11,888.1 million by 2035, growing at a compound annual growth rate (CAGR) of 8.6%.

The FMI report, "Airborne Warning and Control…

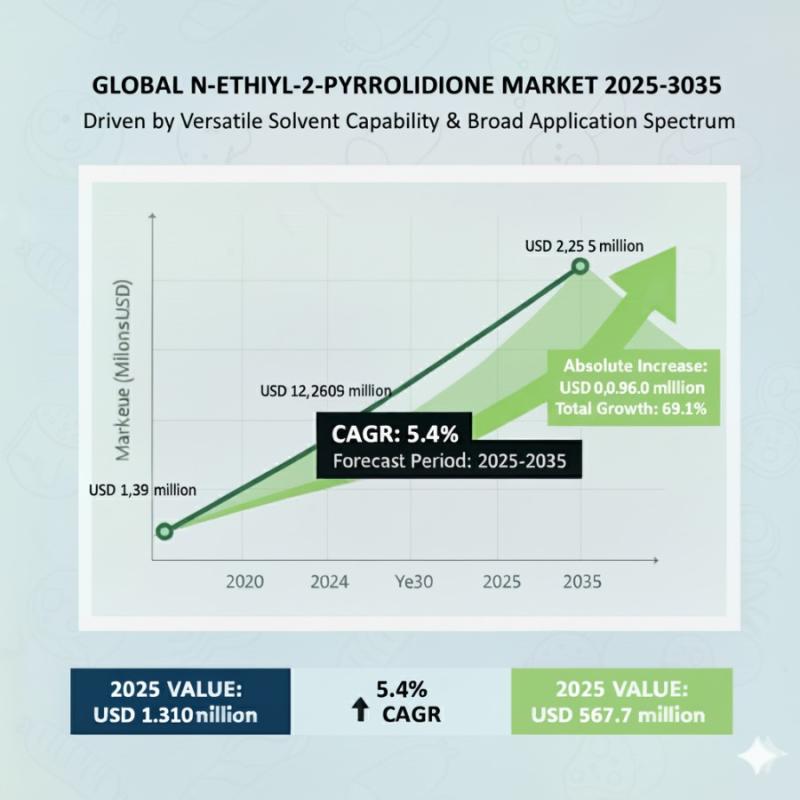

N-Ethyl-2-Pyrrolidone Market to Reach USD 2.35 million by 2035- Steady Growth Le …

The global N-Ethyl-2-Pyrrolidone (NEP) market is poised for consistent expansion through 2035, fueled by rising demand in high-purity electronics, lithium-ion battery production, and pharmaceutical synthesis. According to Future Market Insights (FMI), the market is valued at USD 1.39 million in 2025 and is projected to hit USD 2.35 million by 2035, growing at a compound annual growth rate (CAGR) of 5.4%.

The FMI report, "N-Ethyl-2-Pyrrolidone Market Size, Share, and Forecast 2025-2035,"…

More Releases for Silicone

Revolutionizing Industries: Tenchy Silicone Introduces Cutting-Edge Silicone Tub …

Shenzhen Tenchy Silicone And Rubber Co., Ltd, a renowned leader in silicone products manufacturing, proudly announces the launch of its advanced silicone tubing solutions. Designed to meet the diverse needs of industries such as medical, automotive, and food and beverage, these innovative products represent a significant step forward in silicone technology.

In a world where reliability, performance, and versatility are paramount, silicone tubing stands out as a material of choice for…

Five common properties of silicone and the primary Types of Silicone

Silicones are a versatile class of polymers that come in various forms, offering immense potential for customization to meet the precise needs of the medical and aerospace sectors. Their characteristics enable them to perform diverse functions, such as sealing, lubricating, and fulfilling a host of other tasks.

Silicone's versatility is attributed to its unique physical and mechanical properties, which make it a valuable material in various industries. This article will delve…

Tenchy Silicone: Quality Silicone Tube Supplier for Different Industries

Tenchy Silicone is proud to announce the opening of their new headquarters, which will provide a quality silicone tube supplier service to different industries and businesses. Their silicone tubes are made from FDA-approved materials and are temperature resistant up to 230 degrees Celsius. All products come with an assurance of quality from Tenchy Silicone's team of experienced engineers and technicians who ensure that each product meets customer needs and specifications.…

Tenchy Silicone introducing new silicone foam strip

Tenchy Silicone, the leading provider of high-quality silicone foam strip, is proud to announce their newest product. The Silicone Foam Strip features a combination of both closed-cell and open-cell foaming technologies which offers outstanding thermal insulation and water resistance properties as well as superior airtight performance. It also provides excellent cushioning for equipment, machinery, components and instruments to ensure protection from dust, moisture, abrasion and shock. In addition to its…

Tenchy Silicone Announces Expansion on Silicone Tube Supplier Selection

Tenchy Silicone, a leading silicone tube supplier, is pleased to announce the expansion of its selection of products and services for customers. With over ten years of experience in the industry, the company has established a reputation for providing top-quality silicone tubes that meet customer needs and expectations. The new product line includes tubing from various manufacturers and offers a wide range of materials and sizes to accommodate every project.…

Tenchy Silicone Unveils their New Silicone Seal Gasket

Tenchy Silicone recently released a new silicone seal gasket designed to be used in a variety of industrial applications. It also provides excellent temperature insulation thanks to its ability to withstand temperatures up to 260 °C without any deformation or loss of strength, making it ideal for large-scale industrial projects. The silicone seal gasket is also unaffected by chemicals and ultraviolet light, making it suitable for numerous industries including automotive,…