Press release

Meeting Demands: The Advantages of Vacuum Forming Machines in Production

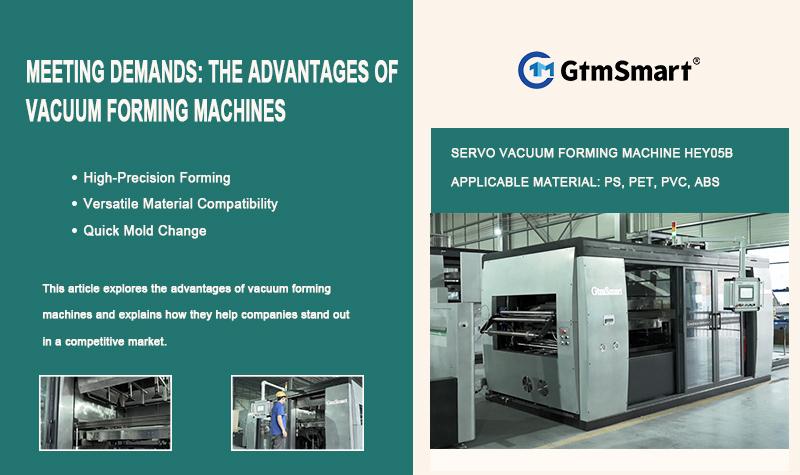

Meeting Demands: The Advantages of Vacuum Forming Machines in ProductionIn today's rapidly evolving manufacturing industry, consumer demand for personalized products is increasing. Manufacturers must respond quickly to market needs, providing high-quality, customized products. Our vacuum forming machines have become essential equipment due to their flexibility and efficiency. This article explores the advantages of vacuum forming machines and explains how they help companies stand out in a competitive market.

Image: https://ecdn6.globalso.com/upload/p/1194/image_product/2024-07/the-advantages-of-vacuum-forming-machines-in-production.jpg

1. Working Principle and Features of Vacuum Forming Machines

A automated vacuum forming machine [https://www.gtmsmart.com/servo-vacuum-forming-machine-hey05b-product/] uses vacuum technology to adhere thermoplastic sheets to the surface of a mold, cooling them into various shapes. Its main features include:

* High-Precision Forming: The vacuum forming machine can precisely control temperature and pressure, ensuring uniform softening of the plastic sheet after heating, resulting in high-precision forming.

* Versatile Material Compatibility: It is suitable for various thermoplastic materials, such as PVC, PET, PS, and PP, meeting the needs of different products.

* Quick Mold Change: Modern plastic vacuum thermal forming machines have a quick mold change function, allowing for rapid switching between different molds, thereby improving production efficiency.

2. Advantages of Vacuum Forming Machines

Flexibility: plastic forming vacuum machines [https://www.gtmsmart.com/servo-vacuum-forming-machine-hey05b-product/] can quickly adjust production processes and molds to meet different customer needs, enabling diverse product customization. Whether for complex shapes or small batch personalized orders, vacuum forming machines can complete them efficiently.

* Efficient Production: Compared to traditional injection molding, vacuum forming machines have shorter production cycles, allowing for faster product forming and processing. For companies that need to respond quickly to market demands, vacuum forming machines are crucial for enhancing production efficiency.

* Cost Advantages: In customized production, mold costs are often a significant challenge for companies. Vacuum forming machines have relatively low mold manufacturing costs and fast mold change speeds, effectively reducing production costs. Additionally, their high material utilization rate minimizes material waste during production.

* Quality Assurance: Commercial vacuum form machines achieve high-precision forming processes, ensuring the quality and consistency of each customized product. Advanced control systems can monitor various parameters in real-time during production, adjusting processes as needed to ensure high-quality output.

3. Recommendations for Choosing Vacuum Forming Machines

Select Equipment Based on Production Needs: Companies should choose vacuum forming machines of appropriate specifications based on their production needs to ensure the equipment meets all production requirements.

Focus on Automation Level: As the automation level of modern vacuum forming machines increases, companies should consider the level of automation when selecting equipment to enhance production efficiency and reduce labor costs.

Prioritize After-Sales Service and Technical Support: When choosing vacuum forming machinery, companies should value the after-sales service and technical support provided by suppliers to ensure timely maintenance and upkeep, extending the equipment's lifespan.

The advantages of vacuum forming machines [https://www.gtmsmart.com/servo-vacuum-forming-machine-hey05b-product/] are evident. Their flexibility, efficiency, and cost advantages make them vital tools for meeting diverse market demands. By choosing the right vacuum forming machines, companies can enhance production efficiency, reduce costs, and ensure high-quality output, securing a competitive edge in the market. With continuous technological advancements, vacuum forming machines will demonstrate their unique advantages in more industries, aiding companies in achieving sustainable development.

Media Contact

Company Name: GTMSMART Machinery Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=meeting-demands-the-advantages-of-vacuum-forming-machines-in-production]

Country: China

Website: https://www.gtmsmart.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Meeting Demands: The Advantages of Vacuum Forming Machines in Production here

News-ID: 3577305 • Views: …

More Releases from ABNewswire

VIP Auto PA: Auto Brokers Near Me Redefine Transparent Car Leasing in Feastervil …

VIP Auto PA continues serving Pennsylvania with transparent, factory-direct car leasing services from its Feasterville-Trevose location, offering zero-down options and no-haggle pricing across all vehicle makes and models.

Feasterville-Trevose, PA - The traditional car-buying experience has long frustrated consumers with high-pressure sales tactics and inflated pricing structures. VIP Auto PA [http://www.vipautopa.com/] continues addressing these industry pain points through a customer-centric brokerage model that has served Pennsylvania drivers since 2007. Operating from…

Austin Nail Salon Dream Spa Expands Service Menu with Apres Gel-X and Holistic W …

Dream Spa in Austin expands with Apres Gel-X nails, infrared sauna, and head spa treatments, offering comprehensive beauty and wellness services at its Airport Boulevard location near downtown Austin.

Dream Spa [https://www.dreamspaatx.com/], located at 5301 Airport Blvd, Suite 200 in Austin, Texas, has announced the expansion of its service offerings to include authentic Apres Gel-X nail extensions, infrared sauna therapy, and signature head spa treatments. The locally established business continues to…

Terrance Private Investigator Expands Houston Private Investigator Services with …

Terrance Private Investigator launches a Houston community program offering consultation, family case support, and professional investigation services to residents facing sensitive personal matters.

A Houston-based investigative firm is taking action to support families facing difficult personal situations. Terrance Private Investigator & Associates [https://piterrance.com/] has announced a new community initiative designed to provide accessible resources and confidential case consultations for residents throughout the Houston area.

The program addresses growing concerns among families facing…

El Monte Agency Strengthens Home Insurance Options and Community Protection Serv …

Marvin Martinez: Allstate Insurance strengthens El Monte's insurance options with bilingual services, comprehensive coverage, and community-focused customer education, earning Elite Agent recognition through consistent service excellence.

El Monte, California - The local insurance landscape continues to evolve as Marvin Martinez, of Allstate Insurance [https://agents.allstate.com/marvin-martinez-el-monte-ca.html?utm_source=GMB&utm_medium=Website], reinforces the company's commitment to protecting families and businesses throughout the San Gabriel Valley. The agency's focus on personalized coverage solutions has positioned it as a trusted…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…