Press release

Thermolysis's innovation and unique technology to recycled carbon fiber.

Recognizing the importance of sustainability in today's world, Thermolysis is dedicated to creating products that can be entirely recycled, starting with recycled materials.we are not only dedicated to making innovative products but also taking responsibility for them. we promise to implement full recycling measures for all future productions, ensuring environmental integrity and promoting carbon fiber recycling.

Our carbon fiber regeneration process is ISO 14067 certified, emitting only one-fifth of the carbon emissions compared to making new fiber.

Carbon fiber composite materials are the go-to for lightweight applications in major industries. However, looking at the carbon footprint of producing carbon fiber raw filaments, there are two big issues.

First, the high energy use in production leads to significant carbon emissions, resulting in higher carbon taxes on the final products. Second, the recycling technology for carbon fiber composite materials is still developing, so high-value carbon fibers often end up as waste after one use, leading to unnecessary resource depletion.

Thermolysis' unique equipment and technology, we can successfully recycle and reuse carbon fibers. This not only greatly reduces carbon fiber waste but also lowers carbon emissions.

Statistics show that producing one ton of new carbon fiber typically results in about 20-40 tons of CO2 emissions. In 2023, Thermolysis had Germany's TÜV Rheinland certify their ISO 14067 carbon footprint standard. The results show that each kilogram of our "recycled carbon fiber" only emits 5.047 kilograms of CO2 equivalent. Compared to new materials, Thermolysis' recycled carbon fiber has just one-fifth the carbon emissions.

We've also achieved UL 2809 certification for recycled material content verification. The source of recycled carbon fiber materials on the market can be unclear and hard to trace, and inconsistent material quality has made the industry wary of using recycled materials. To earn customer trust, Thermolysis got UL to certify the origin of waste materials. Since 2022, We've secured UL 2809 verification, ensuring full transparency and traceability of material history. This certification proves that Thermolysis processes true recycled materials.

Company Profile.

Thermolysis, based in Taiwan, specializes in the production of recycled carbon fiber. Founded in 2016, we focus on continuous innovation, especially in developing and integrating high-temperature thermal treatment systems for "carbon fiber recycling." Since 2020, we've been building carbon fiber recycling and regeneration factory lines, engaging in processing and production of recycled carbon fiber. Using recycled carbon fiber as the main raw material, we create a series of intermediate products designed for smooth integration into the industrial chain.

Recycled carbon fiber is quite different from virgin fiber in shape, being light and fluffy, with variable lengths and an irregular arrangement, posing challenges for further recycling. To deal with this challenge we committed to developing processed products using recycled carbon fiber, aiming to improve the processability and expand the applications of recycled products.

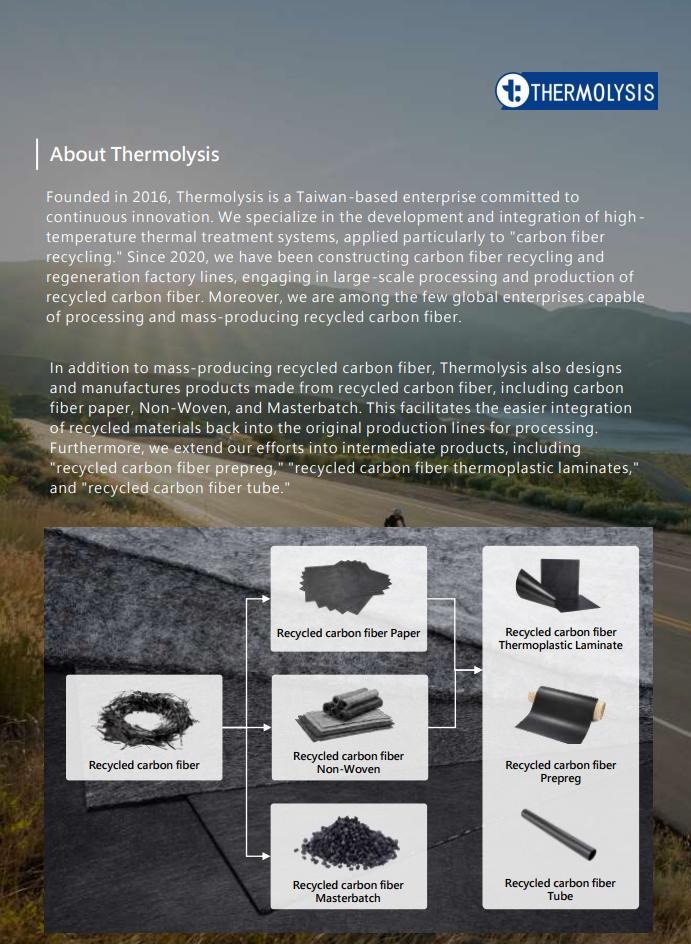

To grow the recycled carbon fiber market, we plan to expand applications to high-value-added products. Besides large-scale recycled carbon fiber production, we meet downstream needs in the carbon fiber industry by designing and manufacturing recycled carbon fiber paper, non-woven materials, and RCF pellets. This ensures a smooth integration of recycled materials into the initial production process.

The "recycled carbon fiber products" developed by Thermolysis include staple fibers, non-woven fabrics, paper, and plastic pellets. These products can be used in both thermosetting and thermoplastic processes. The thermosetting process uses recycled carbon fiber staple for Bulk Molding Compound (BMC) processing. Alternatively, Resin Transfer Molding (RTM) and Sheet Molding Compound (SMC) methods can impregnate "recycled carbon fiber non-woven" and "recycled carbon fiber paper."

The "recycled carbon fiber plastic pellets" made by Thermolysis using Compounding technology are perfect for the injection process, significantly enhancing the mechanical and electrical properties of the finished products and offers excellent characteristics like plastic formability, suitability for mass production, high reprocess ability, and recyclability.

Additionally, "recycled carbon fiber non-woven" and "recycled carbon fiber paper" can be laminated through hot pressing and thermoplastic film materials. Our product line includes intermediate products like "recycled carbon fiber prepregs," "recycled carbon fiber thermoplastic laminates," and "recycled carbon fiber pipes."

TEL:(04)2698-0329

FAX:(04)2698-0330

Email:james.lin@thermolysis-asia.com

Company address:No. 68, Wanxing Rd., Dadu Dist., Taichung City 43241, Taiwan (R.O.C.)

Factory address:No. 16, Tiandan 3rd St., Daliao Dist., Kaohsiung City 83162, Taiwan (R.O.C.)

Thermolysis Co., Ltd. established in 2016. Our core business is the application and development of microwave heating technology, and we are constantly striving for perfection. The proprietary technology "Microwave-Assisted Pyrolysis, MAP" originated from two companies, Norway's MicroFuel AS and Scandinavian Biofuel Company. The technology was supported by The EU 7th Framework Programme from 2009 to 2012 and currently has patents in 19 countries around the world.

In addition of exclusive patent authorization, Thermolysis Co., Ltd has further improved and optimized its technics to meet commercialization needs. We are committed to advance for higher efficiency and zero pollution procedures , providing cleaner and higher value of products.

We believe that innovation is the key to bring the company and the world to a better place.

We focus on the development and application of microwave pyrolysis technology, and constantly try and improve the technology and enhance the performance, thereby expanding our product range. We have product patents, knowledge for pyrolysis tech, experience and factories to make laboratory concepts all the way into commercial products.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Thermolysis's innovation and unique technology to recycled carbon fiber. here

News-ID: 3567233 • Views: …

More Releases for Taiwan

Taiwan Semiconductors Market

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Taiwan Semiconductors Market Size, Share & Trends Analysis Report By Component (Memory Devices, Logic Devices, Analog IC, MPU, Discrete Power Devices, MCU, Sensors, and Others), By Application (Networking & Communications, Data Processing, Industrial, Consumer Electronics, Automotive, and Government), Market Outlook And Industry Analysis 2031"

The Taiwan Semiconductors market is estimated to reach over USD 66.06…

Baseband Processor Packaging Market Research Report 2025 | Global Key Player -AS …

This research report titled “Global Baseband Processor Packaging Market” Size, Status and Forecast 2019-2025 has been added to the wide online database managed by Market Research Hub (MRH). The study discusses the prime market growth factors along with future projections expected to impact the Baseband Processor Packaging Market during the period between 2019 and 2025. The concerned sector is analyzed based on different market factors including drivers, restraints and opportunities…

The Baby Food Sector in Taiwan 2018 | Nestlé Taiwan Ltd, Standard Foods Corpora …

The Baby Food Sector in Taiwan 2018

"The Baby Food Sector in Taiwan, 2018", is an analytical report by Publisher which provides extensive and highly detailed current and future market trends in the Taiwan market.

Western foods are now commonly found on supermarket shelves, and imported foods account for the majority of baby food brands in Taiwan. Although many mothers feed their babies home-made food, demand for commercially prepared baby foods is…

TSMC (Taiwan) Samsung (South Korea) ASE Group (Taiwan) Amkor Technology (U …

Global 2.5D IC Flip Chip Product Market

WiseGuyRerports.com Presents “Global 2.5D IC Flip Chip Product Market Research Report 2019” New Document to its Studies Database. The Report Contain 118 Pages With Detailed Analysis.

Description

This report studies the global 2.5D IC Flip Chip Product market status and forecast, categorizes the global 2.5D IC Flip Chip Product market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top…

Agrochemicals Market in Taiwan

ReportsWorldwide has announced the addition of a new report title Taiwan: Agrochemicals: Market Intelligence (2016-2021) to its growing collection of premium market research reports.

The report “Taiwan: Agrochemicals: Market Intelligence (2016-2021)” provides market intelligence on the different market segments, based on type, active ingredient, formulation, crop, and pest. Market size and forecast (2016-2021) has been provided in terms of both, value (000 USD) and volume (000 KG) in the report. A…

Consumer Payments Country Snapshot: Taiwan 2017 Examines the Consumer Payments m …

"The Report Consumer Payments Country Snapshot: Taiwan 2017 provides information on pricing, market analysis, shares, forecast, and company profiles for key industry participants. - MarketResearchReports.biz"

Taiwan has a very unique payment card environment compared to most other markets. While the infrastructure is in place, with Visa and Mastercard introducing contactless payment capabilities from 2008, point of sale (POS) terminal penetration is only about an eighth of Australia, a similar market…