Press release

Counterpressure Filling Systems with Reliable Vacuum Technology

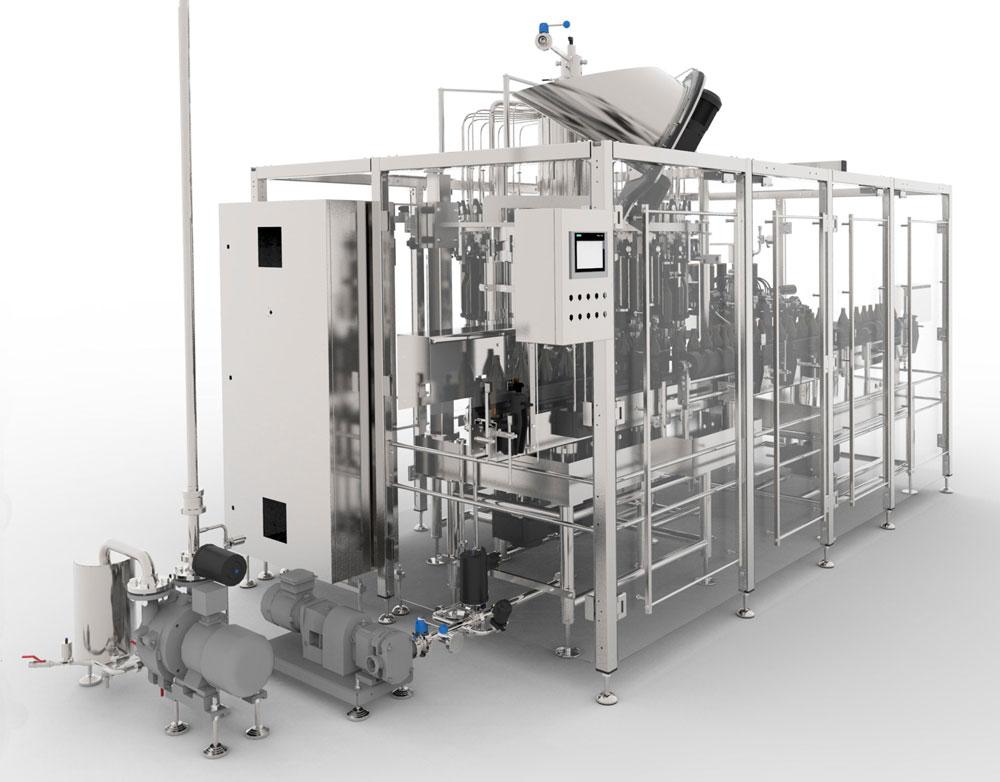

Counterpressure filler systems for carbonated drinks are the main product of Leibinger GmbH in Teningen, southern Germany. The company’s success can be attributed to its combination of the state-of-the-art technology, top quality, equipment flexibility and hygienic design. The integrated vacuum technology supplied by Busch Vacuum Pumps and Systems allows filling to be performed under extremely low oxygen conditions, which improves both shelf life and quality of the drinks.Leibinger manufactures machinery and equipment for bottling and filling carbonated drinks, and produces systems which can rinse, fill and seal between 1,000 and 11,500 bottles or cans per hour. The company originated as Winterwerb, Streng & Co. GmbH in Mannheim in 1909, and in the same year presented the first automatic rotating bottling system as part of an equipment exhibition at the Munich Beer Festival. The company grew to become one of the largest suppliers of bottling equipment and at times employed 500 staff, but declared bankruptcy in 1980. Production continued under the management of Gert Transier SMB Technik GmbH, which was acquired entirely by Benedikt Leibinger in 2008. In April 2009 the company moved to the newly constructed production facility in Teningen. Specialization in equipment for smaller filling volumes proved to be successful, and the company now employs 30 staff. The production area will double in size in 2016 due to increased demand. Leibinger is also extending its international marketing network, and now has distributors throughout the world.

Most of the company’s customers are small breweries with a maximum production capacity of 11,500 bottles or cans per hour. Leibinger equipment is also purchased by larger breweries producing smaller quantities of special beers or beer in different bottle shapes. The increasing trend towards high quality craft beers has been to the company’s advantage, as craft beer brewers value the high quality, reliability and long service lifetime of Leibinger equipment. They also appreciate the flexibility offered by Leibinger systems, which can be easily adapted to a wide range of bottle shapes and sizes by manual adjustment of the filling lines and centring bells. Many customers see the compact dimensions of Leibinger equipment as a decisive advantage, as production space is often limited. Smaller brewers in the USA and Australia in particular have invested in quality equipment “made in Germany” – these countries are currently the main sales markets for Leibinger products.

An important component of counterpressure filler systems is the vacuum pump, which pre-evacuates the bottles to extract the CO2 injected by the flushing process and removes any residual oxygen completely. The empty bottles are then primed with CO2, equalizing the pressure between the bottles and the filling vessel and allowing beer to be filled more rapidly and without foaming. Leibinger Multima counterpressure filler systems (fig. 1) are available with a double pre-evacuation option. Leibinger relies on Busch Dolphin liquid ring vacuum pumps to meet the high standards demanded by the bottle evacuation process. Dolphin liquid ring vacuum pumps are CIP-compliant and require minimal quantities of fresh water for their recirculation systems. The vacuum pumps are equipped with a CIP valve upstream of the gas inlet, allowing the operator to decide whether or not to include the pumps in the CIP process.

From a technical perspective Dolphin liquid ring vacuum pumps (fig. 2) are ideal for this application. They are impervious to water and beer ingestion, and deliver a constant vacuum level. The operating fluid used is water, which is recirculated in an open system. This means that CO2 and air are removed from the water in a downstream container. The water is returned to the vacuum pump, with any losses due to entrained water in the outlet gas stream compensated by the addition of fresh water. This arrangement has the advantage of minimal water consumption. The fresh water added to the system ensures that the recirculation water is gradually replaced, removing any traces of beer and CIP liquids. Fresh water addition also allows the system temperature to be controlled easily.

The water used as an operating fluid forms a so-called liquid ring in the vacuum pump (fig. 3). This ring encloses the compression chamber and forms an airtight seal. The eccentric mounting of the impeller causes this chamber to expand as it rotates, drawing gas into the inlet. Further rotation reduces the volume of the chamber, compressing and expelling the gas through the pump outlet.

This robust vacuum technology guarantees reliable operation and constant vacuum levels. The wide range of Dolphin liquid ring vacuum pumps available from Busch ensures that all sizes of counterpressure filler systems are equipped with a correctly dimensioned vacuum supply.

Busch is based in the same region of southern Germany as Leibinger. Part of the reason for Leibinger’s decision in favour of Busch was to secure a local supplier capable of rapid responses to consultation requests and technical enquiries. Furthermore, Busch is also an internationally active company with its own subsidiaries worldwide, and maintains a comprehensive service network in Leibinger’s export countries. Leibinger’s own maintenance program includes remote access: installed equipment and systems can be analysed via the Internet and instructions given to local service personnel.

Author: Uli Merkle

Contact: www.buschvacuum.com

Busch Vacuum Pumps and Systems is one of the largest manufacturers of vacuum pumps, blowers and compressors in the world.

With a lot of experience and top qualified personnel, we are forward-looking and strive to improve our products and ourselves. We are constantly at work developing innovative technologies that will define the vacuum world of the future.

Our manufacturing plants utilize the most modern manufacturing techniques, machinery and equipment under very strict quality controls, which surpass DIN EN ISO 9001 requirements.

As of 2016, Busch Vacuum Pumps and Systems employs more than 3000 people and features the largest selection of vacuum pumps for the industrial applications in the world. Due to its immense line of vacuum pumps, expertise and experience in the building of vacuum systems and the extensive service network, Busch is capable of providing ideal comprehensive solutions.

With 60 companies in 42 countries and sales agencies worldwide, we are strategically positioned throughout the world to provide our customers with the essentials for success.

Our goal always is to provide the customer with the highest possible return on investment. Personal consulting, choice of the optimum product and prompt service on site are key features of our comprehensive service that make the achievement of this goal reality. Our experience and know how in broadly diversified applications and product design furnish the basis.

Busch’s headquarter is located in Maulburg, Germany. Besides Busch Holding, the German manufacturing plant, Busch Produktions GmbH, the sales organization, Dr.-Ing. K. Busch GmbH and service company, Busch Dienste GmbH are headquartered here. In addition, Busch operates production plants in Switzerland, Great Britain, Czech Republic, Korea and the USA.

Busch Vacuum Pumps and Systems

Marketing/Marketing Services

Uli Merkle

Schauinslandstraße 1

79689 Maulburg

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Counterpressure Filling Systems with Reliable Vacuum Technology here

News-ID: 356270 • Views: …

More Releases from Busch Dienste GmbH

Liquid ring vacuum pumps – Classic vacuum technology and yet still state of th …

Vacuum technology has never stopped developing – not only in the recent past, but for decades it has continued to progress. Today, dry screw vacuum pumps are used in chemical processing technology and many other applications just as dry claw vacuum pumps have established themselves as standard vacuum generators in entire branches of industry. Oil-lubricated rotary vane vacuum pumps are also state of the art in many applications, not least…

Proven vacuum technology fit for Industry 4.0

Busch Vacuum Pumps and Systems enjoyed a great deal of interest from an audience of experts at the IFFA in Frankfurt. The vacuum technology specialist showcased its latest products for the vacuum packaging of meat and sausage products and for meat processing.

Busch also premiered the new R 5 PLUS rotary vane vacuum pump, which is prepared for Industry 4.0. This innovative vacuum pump is based on proven rotary vane vacuum…

Busch solutions for Industry 4.0 at ComVac

The Busch Vacuum Pumps and Systems trade show appearance received a great response from visitors to ComVac, the leading international trade show for compressed air and vacuum technology, held in Hanover, Germany. The interested trade show crowds were able to discover the topic of Vacuum 4.0 and the best-fitting innovative vacuum solutions at Busch.

Numerous visitors took the opportunity to talk to the Busch vacuum experts. With Vacuum 4.0, Busch is…

Dry vacuum systems for centralization of vacuum supply

The concept, design and realization of central vacuum supplies is one of Busch Vacuum Pumps and Systems' core competencies. Thousands of such vacuum systems are in operation worldwide. A wide range of operating principles for generating vacuum in the individual pump modules are applied. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry-compressing vacuum modules can be used, for example in vacuum systems with COBRA NX screw vacuum…

More Releases for Leibinger

Inkjet Print Machine Market Size, Share Report, Growing Demand to 2033 Linx, Vid …

Inkjet print machines use a non-contact printing method that applies liquid ink onto paper or other substrates through tiny nozzles, creating precise dots of color. Unlike traditional printing methods like offset or laser printing, inkjet technology offers high resolution and the ability to print intricate designs, detailed images, and text with smooth gradients. Inkjet printers are popular for both home and professional use, as they are capable of producing vibrant,…

Coding and Marking Equipment Market Expecting Huge Demand in Upcoming Years |Com …

The "Coding And Marking Equipment Market" intelligence report, just published by USD Analytics Market, covers a micro-level study of important market niches, product offers, and sales channels. To determine market size, potential, growth trends, and competitive environment, the Coding And Marking Equipment Market provides dynamic views. Both primary and secondary sources of data were used to generate the research, which has both qualitative and quantitative depth. Several of the major…

Security Printing Market Outlook to 2025 - 3M, Leibinger Group, Gietz, Pozzoni S …

Premium Market Insights reports titled “Security Printing Market” and forecast to 2025 gives a detailed analysis of the market with key company profiles. Security Printing market is evaluated based on two segments i.e., by type and application and covers essential statistics and details for current and future market scenarios. The report actively includes informative aspects relating to product developments, launches, and trends, to assist market players, shareholders, and investors…

Coding and Marking Market – Comprehensive Survey On Demand 2025 | Paul Leibing …

Global Coding and Marking Market: Overview

The global market for coding and marking is projected to witness a steady growth in the next few years. As per the research study, the market is likely to register a 7% CAGR between 2017 and 2021. The rising demand for coding and packaging techniques from several industries, including cosmetic, food and beverage, pharmaceutical, and other industries. The rising competition among the key players has…

Global Coding and Marking System Market To 2025 | KGK, KBA-Metronic, Squid Ink, …

Qyresearchreports include new market research report Global Coding and Marking System Market Professional Survey Report 2018 to its huge collection of research reports.

This report studies Coding and Marking System in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue, consumption, import and export in these regions, from 2013 to 2018, and forecast to 2025.

The global Coding and Marking System market is carefully studied…

Global Security Printer Market 2017 - KBA, LEIBINGER, Goebel, KOMORI, CBPM

Report studies Security Printer in Global market that focuses on the top Manufacturers, Market Segment by Countries, Split by Product Types (with sales, revenue, price, market share of each type), Split by applications this report focuses on sales, market share and growth rate of Security Printer in each application.

This report studies Security Printer in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue,…