Press release

Frozen Sweet Corn Manufacturing Plant Setup Cost Report 2024: Raw Materials and Industry Trends

IMARC Group's report titled "Frozen Sweet Corn Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a frozen sweet corn manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into frozen sweet corn manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful frozen sweet corn manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/frozen-sweet-corn-manufacturing-plant-project-report/requestsample

Customization Available

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

Frozen sweet corn has emerged as a versatile and convenient option for consumers seeking nutritious and easy-to-prepare vegetables. This product retains much of its nutritional value, including essential vitamins, minerals, and fiber, making it a popular choice among health-conscious individuals. The freezing process helps to preserve the natural sweetness and texture of the corn, ensuring a long shelf life without the need for preservatives. This convenience, combined with the ability to enjoy sweet corn year-round, has made frozen sweet corn a staple in many households and a favorite ingredient in various culinary dishes, from soups and salads to casseroles and side dishes.

The market for frozen sweet corn is experiencing significant growth, driven by increasing consumer demand for healthy and convenient food options. According to market research, the global frozen vegetables market is projected to grow at a substantial rate, with frozen sweet corn being a key segment. Factors contributing to this growth include the rising awareness of the nutritional benefits of frozen vegetables, improvements in freezing technology that enhance product quality, and the expanding variety of frozen vegetable products available. Additionally, the growing trend of home cooking and the preference for ready-to-cook meal components have boosted the popularity of frozen sweet corn among busy consumers looking for quick and healthy meal solutions.

Current market trends indicate a shift towards organic and non-GMO frozen sweet corn products, reflecting the broader consumer movement towards natural and sustainable food sources. Brands are responding to this demand by offering products that meet these criteria, often highlighting their sourcing practices and quality standards. Another notable trend is the increasing availability of frozen sweet corn in various cuts and packaging sizes, catering to diverse consumer needs and preferences. Innovations in packaging, such as resealable bags, have also enhanced product convenience and shelf appeal. Furthermore, the growing emphasis on reducing food waste has led to more consumers opting for frozen vegetables like sweet corn, which can be portioned and stored easily, thus minimizing spoilage and ensuring longer usability.

Browse Full Report: https://www.imarcgroup.com/frozen-sweet-corn-manufacturing-plant-project-report

Key Insights Covered the Frozen Sweet Corn Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Frozen Sweet Corn Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=22767&flag=C

Key Questions Addressed in This Report:

• How has the frozen sweet corn market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global frozen sweet corn market?

• What is the regional breakup of the global frozen sweet corn market?

• What are the price trends of various feedstocks in the frozen sweet corn industry?

• What is the structure of the frozen sweet corn industry and who are the key players?

• What are the various unit operations involved in a frozen sweet corn manufacturing plant?

• What is the total size of land required for setting up a frozen sweet corn manufacturing plant?

• What is the layout of a frozen sweet corn manufacturing plant?

• What are the machinery requirements for setting up a frozen sweet corn manufacturing plant?

• What are the raw material requirements for setting up a frozen sweet corn manufacturing plant?

• What are the packaging requirements for setting up a frozen sweet corn manufacturing plant?

• What are the transportation requirements for setting up a frozen sweet corn manufacturing plant?

• What are the utility requirements for setting up a frozen sweet corn manufacturing plant?

• What are the human resource requirements for setting up a frozen sweet corn manufacturing plant?

• What are the infrastructure costs for setting up a frozen sweet corn manufacturing plant?

• What are the capital costs for setting up a frozen sweet corn manufacturing plant?

• What are the operating costs for setting up a frozen sweet corn manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a frozen sweet corn manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a frozen sweet corn manufacturing plant?

• What are the key success and risk factors in the frozen sweet corn industry?

• What are the key regulatory procedures and requirements for setting up a frozen sweet corn manufacturing plant?

• What are the key certifications required for setting up a frozen sweet corn manufacturing plant?

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Frozen Sweet Corn Manufacturing Plant Setup Cost Report 2024: Raw Materials and Industry Trends here

News-ID: 3560947 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

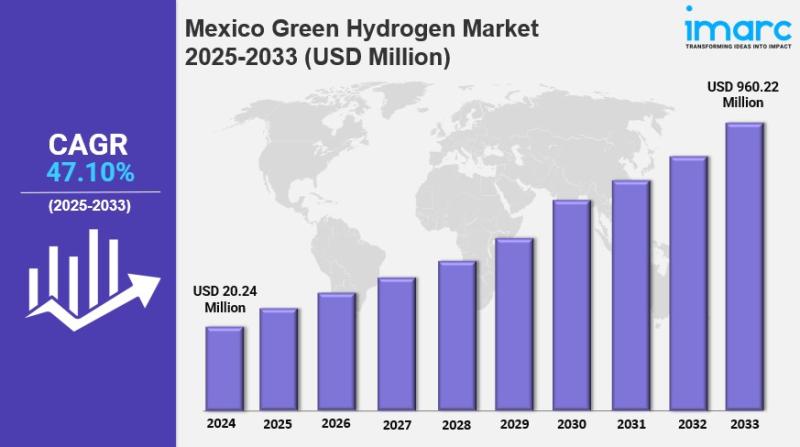

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…