Press release

Paper Core Manufacturing Plant Setup | Raw Material, Machinery, Project Report and Cost Involved

IMARC Group's report, titled "Paper Core Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for setting up a paper core manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into paper core manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful paper core manufacturing unit.

Request For a Sample Report: https://www.imarcgroup.com/paper-core-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

A paper core is a cylindrical tube made from paper or cardboard, used as a central support for winding materials such as paper, plastic films, textiles, and adhesive tapes. These cores provide structural integrity and facilitate the storage, handling, and transportation of wound products. Paper cores are manufactured through a process called spirally or convolutely winding layers of paperboard, which can be customized in terms of diameter, thickness, and length to meet specific requirements. They are widely used in industries such as packaging, textiles, printing, and manufacturing. The eco-friendly nature of paper cores, being recyclable and biodegradable, adds to their appeal, aligning with growing environmental sustainability trends and regulations.

The expansion of the packaging industry, particularly in sectors like food and beverages, pharmaceuticals, and consumer goods, significantly drives the demand for paper cores. These industries rely on paper cores for the efficient winding and storage of various materials, enhancing their logistical processes. The booming e-commerce sector increases the need for robust and reliable packaging solutions. Paper cores play a crucial role in ensuring the safe transport and storage of goods, particularly for items like films, foils, and paper products. The growing environmental awareness and the push for sustainable packaging solutions are key drivers. Paper cores, being recyclable and biodegradable, align with global sustainability goals, making them a preferred choice over plastic alternatives. The textile industry extensively uses paper cores for winding yarns, fabrics, and other materials. The continuous growth in textile production and innovations in fabric technology bolster the demand for paper cores. The printing and labeling industry relies on paper cores for winding printed materials, labels, and adhesive tapes. The need for high-quality printing and labeling solutions in various sectors supports the market growth. Various industrial applications, such as the winding of cables, wires, and specialty films, drive the demand for durable and customizable paper cores. These applications require cores that can withstand significant weight and tension. Innovations in manufacturing processes have led to the production of stronger and more efficient paper cores. The ability to customize cores in terms of size, strength, and material composition to meet specific industry needs further drives market demand. Rapid industrialization and economic growth in emerging markets increase the consumption of paper cores across various sectors, contributing to the overall market expansion.

Browse Full Report with TOC: https://www.imarcgroup.com/paper-core-manufacturing-plant-project-report

Key Insights Covered the Paper Core Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Paper Core Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=8763&flag=C

Key Questions Addressed in This Report:

• How has the paper core market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global paper core market?

• What is the regional breakup of the global paper core market?

• What are the price trends of various feedstocks in the paper core industry?

• What is the structure of the paper core industry and who are the key players?

• What are the various unit operations involved in a paper core manufacturing plant?

• What is the total size of land required for setting up a paper core manufacturing plant?

• What is the layout of a paper core manufacturing plant?

• What are the machinery requirements for setting up a paper core manufacturing plant?

• What are the raw material requirements for setting up a paper core manufacturing plant?

• What are the packaging requirements for setting up a paper core manufacturing plant?

• What are the transportation requirements for setting up a paper core manufacturing plant?

• What are the utility requirements for setting up a paper core manufacturing plant?

• What are the human resource requirements for setting up a paper core manufacturing plant?

• What are the infrastructure costs for setting up a paper core manufacturing plant?

• What are the capital costs for setting up a paper core manufacturing plant?

• What are the operating costs for setting up a paper core manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a paper core manufacturing plant?

• What is the time required to breakeven?

• What are the profit projections for setting up a paper core manufacturing plant?

• What are the key success and risk factors in the paper core industry?

• What are the key regulatory procedures and requirements for setting up a paper core manufacturing plant?

• What are the key certifications required for setting up a paper core manufacturing plant?

Browse Other Report By IMARC Group:

• Plastic Bag Manufacturing Plant Project Report: https://www.imarcgroup.com/plastic-bag-manufacturing-plant-project-report

• Aluminum Foil Manufacturing Plant Project Report: https://www.imarcgroup.com/aluminum-foil-manufacturing-plant-project-report

• Aluminum Food Container Manufacturing Plant Project Report: https://www.imarcgroup.com/aluminum-food-container-manufacturing-plant-project-report

• Disposable Garbage Bag Manufacturing Plant Project Report: https://www.imarcgroup.com/disposable-garbage-bag-manufacturing-plant-project-report

• Suitcase Manufacturing Plant Project Report: https://www.imarcgroup.com/suitcase-manufacturing-plant-project-report

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: Sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

Phone Number: - +1 631 791 1145, +91-120-433-0800

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Paper Core Manufacturing Plant Setup | Raw Material, Machinery, Project Report and Cost Involved here

News-ID: 3559458 • Views: …

More Releases from IMARC Group

Liquefied Natural Gas (LNG) Manufacturing Plant DPR & Unit Setup Report 2026

Setting up a Liquefied Natural Gas (LNG) manufacturing plant positions investors in one of the most strategically vital and rapidly expanding segments of the global energy value chain, backed by sustained growth driven by the rising global demand for cleaner-burning fuels in power generation, widespread adoption of LNG in the marine and transportation sector as a fuel, and supporting energy security initiatives through long-term supply contracts. As countries quicken their…

Generic Injectables Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, …

Setting up a Generic Injectables Manufacturing Plant requires meticulous planning, strict regulatory compliance, and advanced sterile manufacturing infrastructure. Generic injectable drugs are widely used in hospitals and healthcare facilities for treating critical conditions, chronic diseases, and emergency care. Due to their direct administration into the bloodstream or tissues, manufacturing quality, sterility, and safety standards are significantly higher than for oral formulations. As healthcare systems worldwide transition toward cost-effective treatment solutions…

Fantasy Sports Market in India 2026: Size, Share, Growth Rate & Industry Forecas …

India Fantasy Sports Market Overview

According to IMARC Group's report titled "India Fantasy Sports Market Size, Share, Trends and Forecast by Sports Type, Platform, Demographics, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The India fantasy sports market size was valued at USD 27.0 Billion in 2025. IMARC Group estimates that the market will expand to reach USD 519.8 Billion…

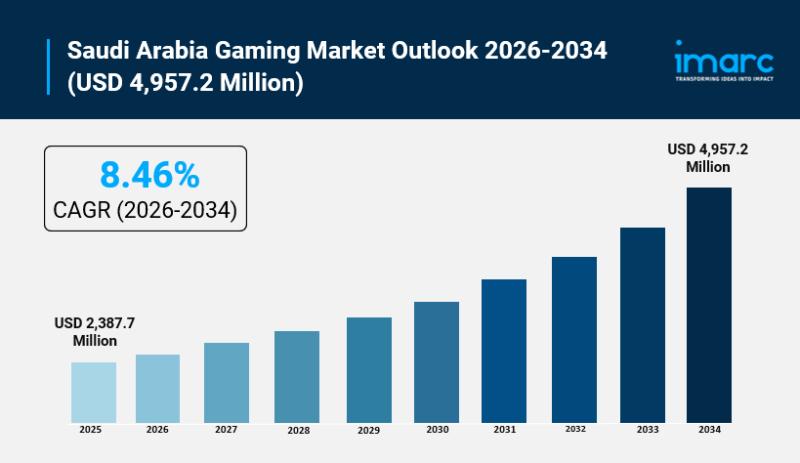

Saudi Arabia Gaming Market is Set For Strong Growth, Projected to Reach USD 4,95 …

Saudi Arabia Gaming Market Overview

Market Size in 2025: USD 2,387.7 Million

Market Forecast in 2034: USD 4,957.2 Million

Market Growth Rate 2026-2034: 8.46%

According to IMARC Group's latest research publication, "Saudi Arabia Gaming Market Report by Device Type (Consoles, Mobiles and Tablets, Computers), Platform (Online, Offline), Revenue (In-Game Purchase, Game Purchase, Advertising), Type (Adventure/Role Playing Games, Puzzles, Social Games, Strategy, Simulation, and Others), Age Group (Adult, Children), and Region 2026-2034", the Saudi Arabia…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…