Press release

Aluminum Extrusion Manufacturing Plant Project Report 2024: Raw Materials, Investment Opportunities, Cost and Revenue

IMARC Group's report, titled "Aluminum Extrusion Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for setting up an aluminum extrusion manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into aluminum extrusion manufacturing plant process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful aluminum extrusion manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/aluminum-extrusion-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

Aluminum extrusion, a pivotal process in metal fabrication, revolutionizes the creation of intricate and customized aluminum profiles. By forcing aluminum alloys through a shaped die, this method transforms simple, malleable material into complex cross-sectional shapes for various applications. From sleek architectural components to durable automotive parts, aluminum extrusion offers unparalleled versatility, combining strength with lightweight properties. As an essential technique in modern manufacturing, it epitomizes precision and efficiency, meeting the diverse needs of industries seeking resilient and customizable solutions for structural and design challenges. Aluminum extrusion stands as an integral process, shaping the landscape of contemporary metal fabrication.

The aluminum extrusion market is propelled by key drivers and dynamic trends that underscore its crucial role in diverse industries. A major driver is the increasing demand for lightweight and durable materials in sectors such as automotive, construction, and aerospace. Aluminum extrusion provides a solution, offering strength and versatility while significantly reducing the overall weight of structures and components. Technological advancements contribute to market growth, with innovations in extrusion processes enhancing efficiency and precision. Continuous research and development focus on optimizing the extrusion of aluminum alloys to meet evolving industry standards and specifications. Moreover, sustainability is a prevailing trend shaping the market. Aluminum, being a recyclable material, aligns with the growing emphasis on eco-friendly practices. The recyclability of aluminum extrusions caters to the sustainability goals of industries seeking environmentally responsible solutions. Customization is another notable trend. The ability of aluminum extrusion to create intricate and tailor-made profiles aligns with the increasing demand for personalized designs in architecture, furniture, and consumer goods. In conclusion, the aluminum extrusion market is driven by the demand for lightweight and sustainable materials, technological advancements, and the trend towards customization.

Browse Full Report with TOC: https://www.imarcgroup.com/aluminum-extrusion-manufacturing-plant-project-report

Key Insights Covered the Aluminum Extrusion Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Aluminum Extrusion Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=18627&flag=C

Key Questions Addressed in This Report:

• How has the aluminum extrusion market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global aluminum extrusion market?

• What is the regional breakup of the global aluminum extrusion market?

• What are the price trends of various feedstocks in the aluminum extrusion industry?

• What is the structure of the aluminum extrusion industry and who are the key players?

• What are the various unit operations involved in an aluminum extrusion manufacturing plant?

• What is the total size of land required for setting up an aluminum extrusion manufacturing plant?

• What is the layout of an aluminum extrusion manufacturing plant?

• What are the machinery requirements for setting up an aluminum extrusion manufacturing plant?

• What are the raw material requirements for setting up an aluminum extrusion manufacturing plant?

• What are the packaging requirements for setting up an aluminum extrusion manufacturing plant?

• What are the transportation requirements for setting up an aluminum extrusion manufacturing plant?

• What are the utility requirements for setting up an aluminum extrusion manufacturing plant?

• What are the human resource requirements for setting up an aluminum extrusion manufacturing plant?

• What are the infrastructure costs for setting up an aluminum extrusion manufacturing plant?

• What are the capital costs for setting up an aluminum extrusion manufacturing plant?

• What are the operating costs for setting up an aluminum extrusion manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for an aluminum extrusion manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up an aluminum extrusion manufacturing plant?

• What are the key success and risk factors in the aluminum extrusion industry?

• What are the key regulatory procedures and requirements for setting up an aluminum extrusion manufacturing plant?

• What are the key certifications required for setting up an aluminum extrusion manufacturing plant?

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: Sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

Phone Number:- +1 631 791 1145, +91-120-433-0800

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Extrusion Manufacturing Plant Project Report 2024: Raw Materials, Investment Opportunities, Cost and Revenue here

News-ID: 3559315 • Views: …

More Releases from IMARC Group

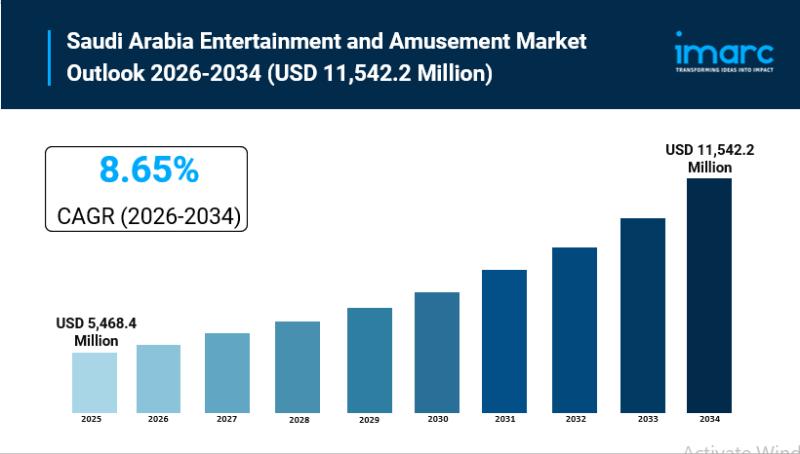

Saudi Arabia Entertainment and Amusement Market Size to Reach USD 11,542.2 Milli …

Saudi Arabia Entertainment and Amusement Market Overview

Market Size in 2025: USD 5,468.4 Million

Market Size in 2034: USD 11,542.2 Million

Market Growth Rate 2026-2034: 8.65%

According to IMARC Group's latest research publication, "Saudi Arabia Entertainment and Amusement Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Saudi Arabia entertainment and amusement market size reached USD 5,468.4 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 11,542.2 Million…

Philippines Wound Care Market 2026 | Worth USD 175.8 Million by 2034 | At a CAGR …

Market Overview

The Philippines wound care market size reached USD 111.4 Million in 2025. Looking forward, the market is expected to reach USD 175.8 Million by 2034, exhibiting a growth rate (CAGR) of 5.20% during 2026-2034. The market is expanding due to rising awareness of advanced treatments, greater healthcare access, and demand for innovative products such as hydrocolloid dressings and antimicrobial solutions. Growing hospital investments, home healthcare adoption, and focus on…

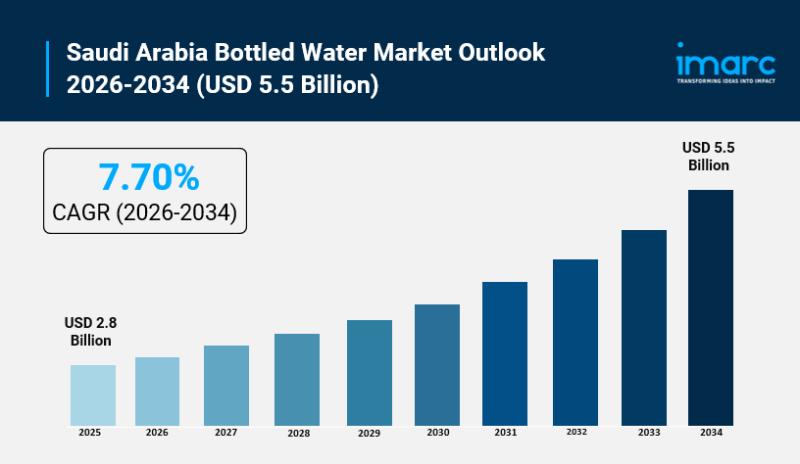

Saudi Arabia Bottled Water Market Size to Surpass USD 5.5 Billion by 2034 at a C …

Saudi Arabia Bottled Water Market Overview

Market Size in 2025: USD 2.8 Billion

Market Size in 2034: USD 5.5 Billion

Market Growth Rate 2026-2034: 7.70%

According to IMARC Group's latest research publication, "Saudi Arabia Bottled Water Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia bottled water market size was valued at USD 2.8 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 5.5 Billion by…

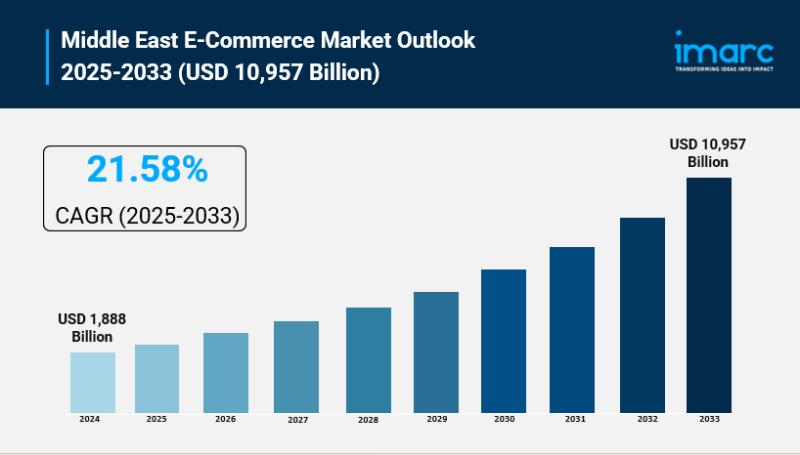

Middle East E-Commerce Market Size to Hit USD 10,957 Billion by 2033 | With a 21 …

Middle East E-Commerce Market Overview

Market Size in 2024: USD 1,888 Billion

Market Size in 2033: USD 10,957 Billion

Market Growth Rate 2025-2033: 21.58%

According to IMARC Group's latest research publication, "Middle East E-Commerce Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the Middle East e-commerce market size was valued at USD 1,888 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 10,957 Billion by 2033, exhibiting a…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…