Press release

Dry Ramming Mass Market worth $3.2 billion by 2028 | Key players Saint-Gobain (France), Dense Refractories Co., Ltd. (China), Imperial World Trade Private Limited (India), Casco Specialty Products, Inc. (US).

Dry Ramming Mass Market, Dry Ramming Mass, Ramming Mass, Europe Dry Ramming Mass Market, APAC Dry Ramming Mass Market

Browse 201 market data Tables and 41 Figures spread through 221 Pages and in-depth TOC on "Dry Ramming Mass Market - Global Forecast to 2028"

View detailed Table of Content here - https://www.marketsandmarkets.com/Market-Reports/dry-ramming-mass-market-252792065.html

In the steel industry, dry ramming mass plays a crucial role. It finds diverse applications in various steelmaking processes, including lining ladles for the transportation and pouring of molten steel, constructing covers for ladles to retain heat during transportation, lining tundishes for the temporary holding and distribution of molten metal during continuous casting, and providing refractory lining in reheat furnaces used to bring steel ingots or slabs to desired temperatures. Additionally, dry ramming mass is utilized in the lining of steel crucibles for smaller-scale alloy production, in pouring channels and troughs to guide molten steel from furnaces to molds, ensuring a controlled and smooth flow during casting processes. Furthermore, it contributes to the thermal stability and wear resistance of mixer furnaces employed in blending different grades of steel or alloys. The versatility of dry ramming mass makes it an integral component in enhancing the efficiency, durability, and quality of various steel manufacturing applications.

Alumina ramming mass stands out as a preferred choice in specific applications owing to its distinctive properties that confer several advantages over silica and magnesia-based ramming masses. Comprising primarily high-alumina aggregates, often exceeding 80% alumina content, it ensures excellent refractoriness and resistance to high temperatures. Notably, its commendable thermal shock resistance proves crucial in environments characterized by rapid temperature fluctuations, as commonly encountered in metal melting and casting processes. Well-suited for non-ferrous metal applications, particularly in the melting and holding of metals like aluminum and its alloys, alumina ramming mass boasts chemical inertness, preventing undesirable reactions with molten metals or slags and thereby ensuring the stability of the lining. The material's versatility extends to various non-ferrous metal melting processes, underlining its adaptability to diverse industrial applications. Further enhancing its utility, alumina ramming mass exhibits notable abrasion resistance, contributing to the longevity and durability of refractory linings within furnaces. The adaptability of alumina ramming mass to different furnace designs and operating conditions adds a layer of flexibility to its application, making it a versatile and reliable choice across a spectrum of industrial settings.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=252792065

The Asia Pacific region has become a focal point for the increased demand in refractory materials, particularly dry ramming mass, owing to a confluence of factors. Rapid industrialization in countries such as China, India, Japan, Thailand, Vietnam, Malaysia and Indonesia have spurred growth in steel, non-ferrous metals, and foundry industries, amplifying the need for reliable refractory solutions. China, as the world's largest steel producer, stands out as a major consumer of refractories, significantly driving the demand for dry ramming mass. The region's extensive construction and infrastructure projects, coupled with the establishment of new industrial facilities, further contribute to the escalating demand for refractory materials. Diverse manufacturing activities encompassing automotive, electronics, and heavy machinery production in the region intensify the reliance on furnaces and high-temperature equipment, necessitating steadfast refractory linings. The rise in non-ferrous metal production, including aluminum, copper, and zinc, underscores the critical role of dry ramming mass in the construction and maintenance of furnaces for these expanding industries. The energy and petrochemical sectors in countries like China and India are on the ascent, demanding refractory materials for furnaces and reactors, fostering sustained growth. Government initiatives supporting industrial growth and infrastructure development, coupled with a competitive manufacturing landscape featuring numerous refractory material suppliers, contribute to the robust market for dry ramming mass. Moreover, technological advancements in manufacturing processes enhance the quality and performance of refractory materials, driving the adoption of advanced dry ramming mass products across diverse industrial applications in the region.

The key players in this market are Saint-Gobain (France), Dense Refractories Co., Ltd. (China), Imperial World Trade Private Limited (India), Vishva Vishal Refractory Limited (India), Refcast Corporation (India), Henan Xinmi Changxing Refractory Material Co., Ltd. (China), Casco Specialty Products, Inc. (US), Gita Refractories Private Limited (India), Shenghe Refractories (China), RHI Magnesita N.V. (Austria) etc.

Request Sample Pages @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=252792065

Established in 2007, Dense Refractories Co., Ltd. has emerged as a prominent manufacturer of refractory materials in China. Headquartered in Zibo City, Shandong Province, the company boasts a comprehensive portfolio of high-quality refractory products, including castable refractories, precast shapes, dry ramming mixes, and specialized refractory materials. Catering to diverse industries such as steel, cement, aluminum, glass, and power generation, Dense Refractories Co., Ltd. is committed to delivering exceptional products, unparalleled service, and innovative solutions to its customers.

Strategically located manufacturing facilities in Zibo, Hebei, Henan, and Jiangsu enable Dense Refractories Co., Ltd. to efficiently produce and deliver its products to customers across the country. The company's operations are organized into three distinct segments: the Steel Industry Segment, the Cement Industry Segment, and the Aluminum Industry Segment, allowing for focused expertise and tailored solutions for each industry's specific needs.

Make an Enquiry @ https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=252792065

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA: +1-888-600-6441

Email: sales@marketsandmarkets.com

Press Release: https://www.marketsandmarkets.com/PressReleases/dry-ramming-mass.asp

Research Insights: https://www.marketsandmarkets.com/ResearchInsight/dry-ramming-mass-market.asp

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we made a formal transformation into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Dry Ramming Mass Market worth $3.2 billion by 2028 | Key players Saint-Gobain (France), Dense Refractories Co., Ltd. (China), Imperial World Trade Private Limited (India), Casco Specialty Products, Inc. (US). here

News-ID: 3556406 • Views: …

More Releases from MarketsandMarkets

Top Ultrasound Market Trends Driving Growth in 2025 and Beyond | Philips Healthc …

The global ultrasound market is entering a transformative phase in 2025. Once primarily associated with pregnancy scans and basic imaging, ultrasound has now evolved into a powerful, multipurpose diagnostic tool with applications across cardiology, oncology, musculoskeletal care, emergency medicine, and beyond.

As healthcare systems worldwide shift towards non-invasive, affordable, and portable imaging solutions, ultrasound is becoming central to modern diagnostics. According to market insights, the ultrasound industry is poised for steady…

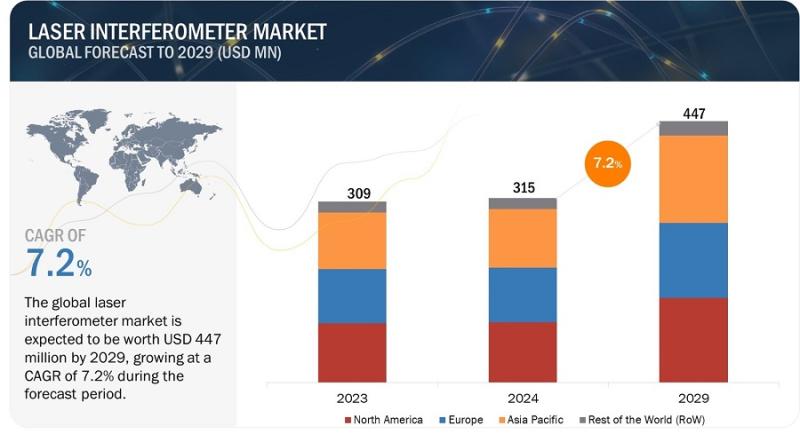

Laser Interferometer Market Set to Grow at the Fastest Rate- Time to Grow your R …

The global laser interferometer market is expected to be valued at 315 million in 2024 and is projected to reach USD 447 million by 2029, at a CAGR of 7.2% from 2024 to 2029. Emerging applications in industries push the market's growth due to the growing demand for precision in the manufacturing sector. However, challenges such as higher initial investments and maintenance costs cause problems. Despite these, opportunities arise for…

With 19.6% CAGR, Battery Testing, Inspection, and Certification Market Growth to …

The battery testing, inspection, and certification market is projected to reach USD 36.7 billion by 2029 from USD 14.9 billion in 2024 at a CAGR of 19.6% during the forecast period. Increasing adoption of EVs and energy storage systems, rising enforcement of stringent standards to ensure battery safety, thriving portable electronics industry, and rapid advances in battery technology are the major factors contributing to the market growth.

Download PDF Brochure @…

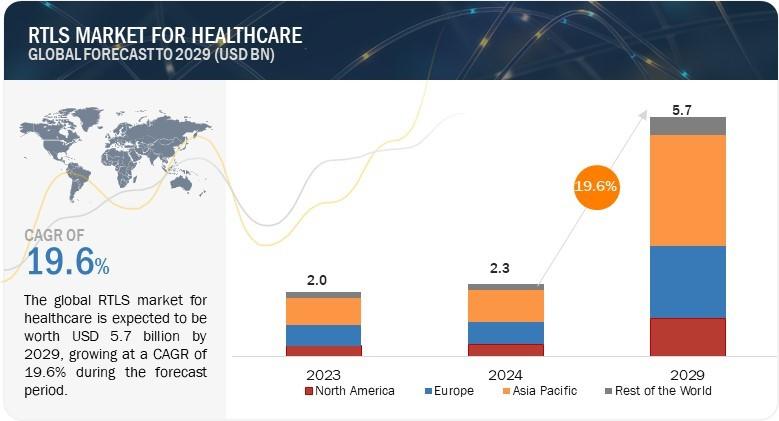

Real-Time Location Systems Revolutionize Healthcare: Insights from MarketsandMar …

The global RTLS market for healthcare is projected to grow from USD 2.3 billion in 2024 to USD 5.7 billion by 2029, at a compound annual growth rate of 19.6% from 2024 to 2029. As it attracts more and more players who enter this market with innovative RTLS features for customers, the market for RTLS technology is rapidly increasing. Top companies in this market focus on healthcare, retail, and manufacturing…

More Releases for Ramming

Acidic Ramming Mass Market Research Report: Sales, Volume, Revenue and Players A …

Global Info Research's report is a detailed and comprehensive analysis for global Acidic Ramming Mass market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the Acidic Ramming Mass market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product…

How To Setup a Silica Ramming Mass Manufacturing Plant

Setting up a silica ramming mass manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Silica Ramming Mass Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Dry Ramming Mass Market Outlook and Future Projections for 2030

The dry ramming mass market represents a dynamic and continually evolving landscape, shaped by changing consumer demands and technological advancements. In this comprehensive report, we provide an in-depth exploration of the market, designed for a wide range of stakeholders including manufacturers, suppliers, distributors, and investors. Our goal is to equip industry participants with essential insights that enable informed decision-making in an ever-changing market environment. This analysis not only examines the…

Silica Ramming Mass Manufacturing Plant Project Report: Machinery Requirements a …

IMARC Group's report titled "Silica Ramming Mass Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a silica ramming mass manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In…

Refractory Ramming Material Market Analysis and Future Prospects for 2030

The refractory ramming material market represents a multifaceted and continually evolving realm, influenced by shifting consumer demands and technological advancements. In this comprehensive report, we embark on a thorough exploration of this market landscape, catering to a diverse audience ranging from manufacturers and suppliers to distributors and investors. Our primary objective is to arm industry stakeholders with indispensable insights, enabling them to make well-informed decisions within the swiftly changing market…

Neutral Ramming Mass Market 2023-2031: Unveiling Growth Trajectory

The global neutral ramming mass market is poised for substantial growth between 2023 and 2031, driven by increasing demand from the steel industry and infrastructure development projects worldwide. Neutral ramming mass is a refractory lining material used in induction furnaces, ladles, and other high-temperature applications for steelmaking processes.

Neutral ramming mass, composed primarily of magnesia and aluminum oxide, exhibits excellent resistance to thermal shock and erosion, making it ideal for lining…