Press release

Detailed Report on Glucometer Manufacturing Plant Setup Cost, Layout and Raw Material Requirements

IMARC Group's report titled "Glucometer Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an glucometer manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into glucometer manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful glucometer manufacturing unit.

Request For a Sample Report: https://www.imarcgroup.com/glucometer-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

A glucometer, also known as a blood glucose meter or blood sugar monitor, is a small yet powerful device that has revolutionized the lives of millions globally. This handheld tool is crucial for managing diabetes, a chronic condition marked by irregular blood sugar levels. By providing a quick and accurate measure of blood glucose from a simple fingertip prick, glucometers enable individuals to track their health effectively. This empowers them to make informed decisions about their diet, medication, and lifestyle, ensuring better diabetes management. The convenience of monitoring blood sugar levels at home or on the go has made glucometers an indispensable part of diabetic care.

The glucometer market is rapidly evolving, influenced by several key factors and emerging trends. With the global rise in diabetes prevalence, there is a growing demand for reliable and convenient blood glucose monitoring tools. This shift is driving the market as more individuals seek efficient ways to manage their condition. Awareness of proactive healthcare and preventive measures is also increasing, contributing to the market's growth. Smart glucometers, which sync data with mobile apps for real-time monitoring and analysis, are becoming increasingly popular. Additionally, the development of non-invasive or minimally invasive glucometers offers pain-free alternatives to traditional methods. Integration with telemedicine and digital health platforms further enhances patient care, allowing healthcare providers to offer personalized advice and treatment remotely.

Browse Full Report with TOC: https://www.imarcgroup.com/glucometer-manufacturing-plant-project-report

Key Insights Covered the Glucometer Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Glucometer Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=11976&flag=C

Key Questions Addressed in This Report:

• How has the glucometer market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global glucometer market?

• What is the regional breakup of the global glucometer market?

• What are the price trends of various feedstocks in the glucometer industry?

• What is the structure of the glucometer industry and who are the key players?

• What are the various unit operations involved in a glucometer manufacturing plant?

• What is the total size of land required for setting up a glucometer manufacturing plant?

• What is the layout of a glucometer manufacturing plant?

• What are the machinery requirements for setting up a glucometer manufacturing plant?

• What are the raw material requirements for setting up a glucometer manufacturing plant?

• What are the packaging requirements for setting up a glucometer manufacturing plant?

• What are the transportation requirements for setting up a glucometer manufacturing plant?

• What are the utility requirements for setting up a glucometer manufacturing plant?

• What are the human resource requirements for setting up a glucometer manufacturing plant?

• What are the infrastructure costs for setting up a glucometer manufacturing plant?

• What are the capital costs for setting up a glucometer manufacturing plant?

• What are the operating costs for setting up a glucometer manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a glucometer manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a glucometer manufacturing plant?

• What are the key success and risk factors in the glucometer industry?

• What are the key regulatory procedures and requirements for setting up a glucometer manufacturing plant?

• What are the key certifications required for setting up a glucometer manufacturing plant?

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: Sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

Phone Number: - +1 631 791 1145, +91-120-433-0800

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Detailed Report on Glucometer Manufacturing Plant Setup Cost, Layout and Raw Material Requirements here

News-ID: 3550330 • Views: …

More Releases from IMARC Group

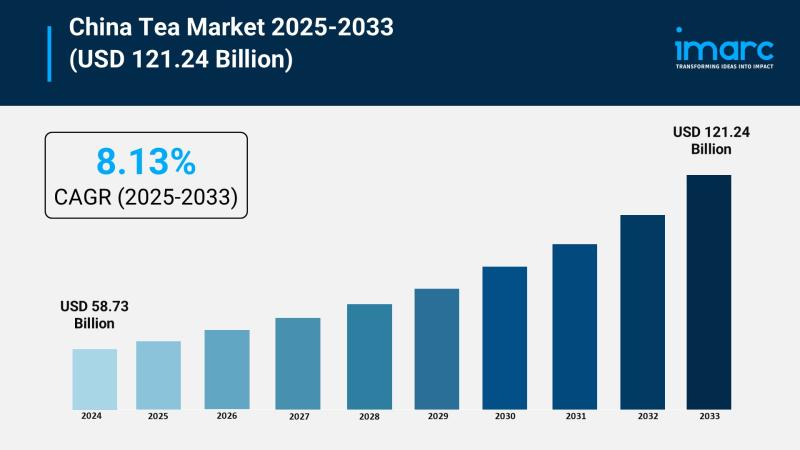

China Tea Market Forecast CAGR of 8.13%, Innovation Trends, and Strategic Insigh …

Market Overview

The China tea market was valued at USD 58.73 Billion in 2024 and is projected to reach USD 121.24 Billion by 2033, growing at a CAGR of 8.13% during 2025-2033. Growth is driven by rising health consciousness, premium product trends, government support, and expanding online retail. Innovation in flavors and packaging attracts younger consumers and global buyers, expanding the market.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

China Tea…

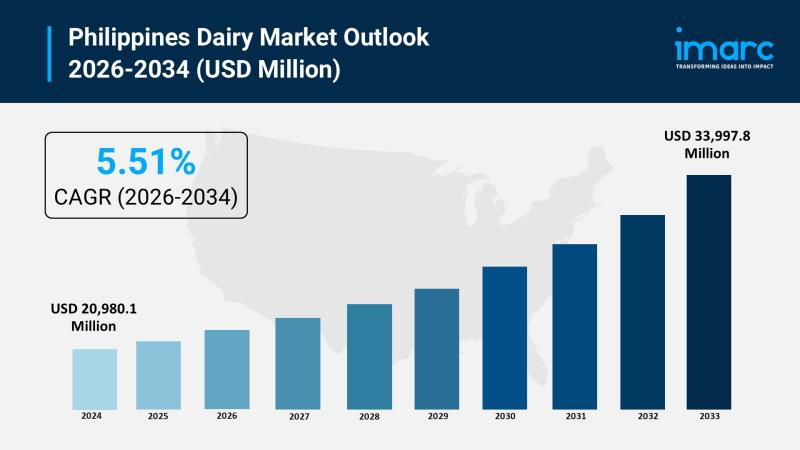

Philippines Dairy Market 2026: Expected to Reach USD 33,997.8 Million by 2034

Market Overview

The Philippines dairy market reached a size of USD 20,980.1 Million and is anticipated to grow to USD 33,997.8 Million by 2034 with a significant growth rate of 5.51%. This expansion is driven by rising demand for nutritious and diverse dairy products, rapid urbanization, increased disposable incomes, improved retail infrastructure, and strong government initiatives promoting local dairy production. Health-conscious consumers and expanding food service sectors further fuel this growth…

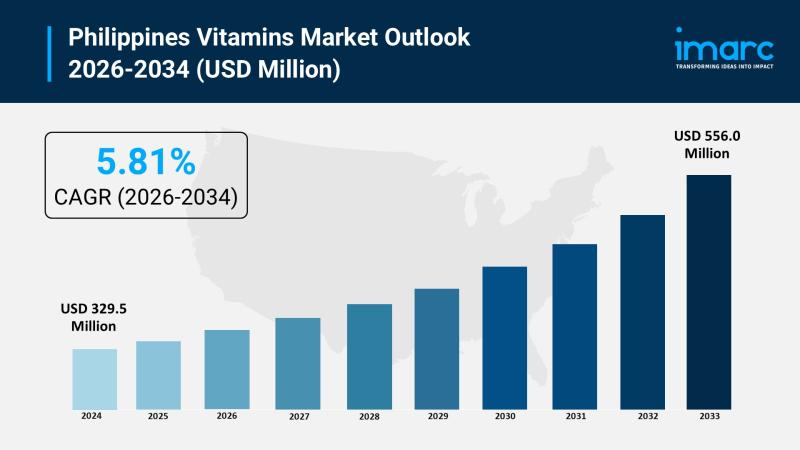

Philippines Vitamins Market 2026 | Projected to Reach USD 556.0 Million by 2034

Market Overview

The Philippines vitamins market was valued at USD 329.5 Million in 2025 and is projected to reach USD 556.0 Million by 2034, growing steadily over the forecast period. The market's growth is driven by increasing health consciousness, a rising geriatric population, and escalating demand for supplements that support immunity, energy, and overall wellness due to proactive health measures. The forecast period for this expansion is 2026-2034, with a CAGR…

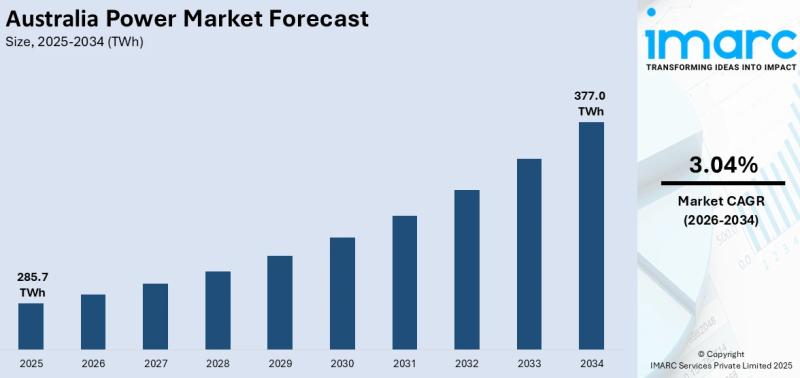

Australia Power Market Projected to Reach TWH 377 by 2034

Market Overview

The Australia power market size reached 285.7 TWh in 2025 and is projected to grow to 377.0 TWh by 2034, with a CAGR of 3.04% during the forecast period of 2026-2034. This growth is driven by rising renewable energy adoption, increased electricity demand, grid modernization, battery storage expansion, transition from coal plants, and government incentives for clean power. Key strategies such as virtual power plant integration and investments in…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…